Reinforced aramid honeycomb sandwich plate

An aramid honeycomb and sandwich technology, applied in the field of enhanced aramid honeycomb sandwich panels, can solve the problems of weak honeycomb panels, poor impact resistance, low bonding strength, etc., achieve excellent thermal stability and improve impact resistance. performance, the effect of improving the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

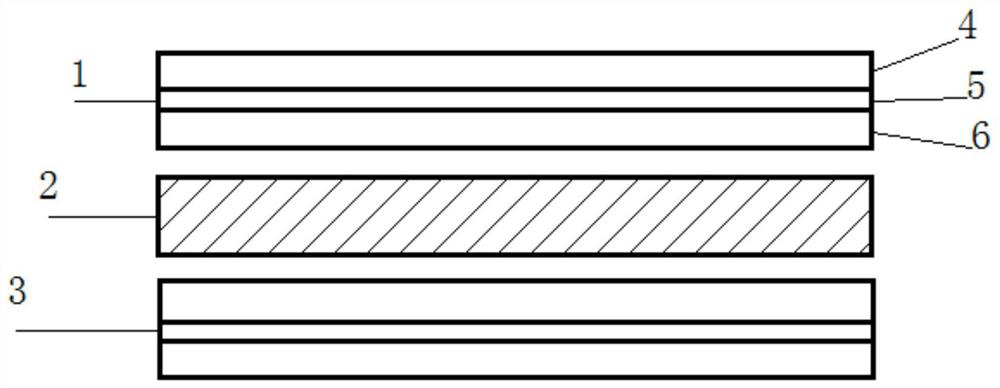

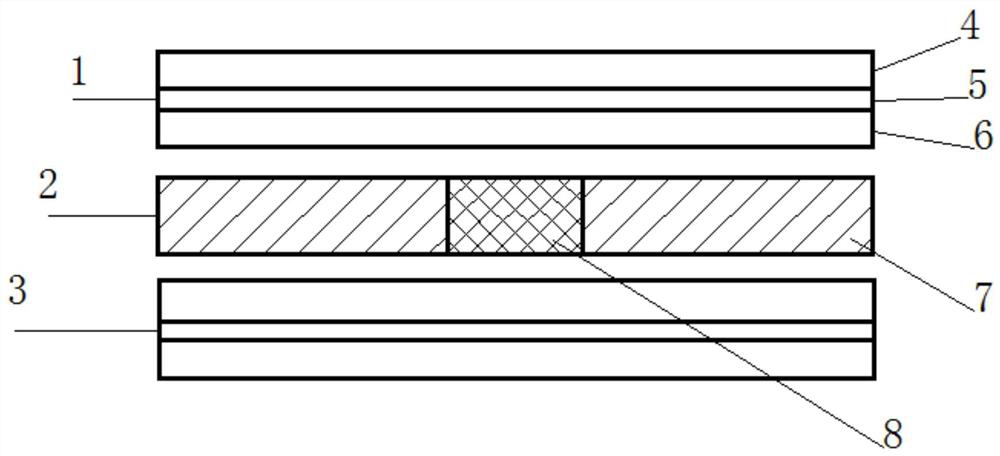

[0055] A reinforced version of the aramid honeycomb sandwich panel, which is composed of an upper skin layer, a middle aramid honeycomb core layer and a lower skin layer. The periphery of the aramid honeycomb core layer and the lower skin layer is sealed with edge banding profiles;

[0056] The thickness of the upper skin layer is 0.9mm, the thickness of the middle aramid honeycomb core layer is 10mm, and the thickness of the lower skin layer is 0.9mm; the wall thickness of each cell in the middle aramid honeycomb core is the same, 0.18mm;

[0057] Both the upper skin and the lower skin have a three-layer composite structure. The upper and lower layers are carbon fiber / PEEK resin panels. The curing temperature is 100℃, the time is 1h, the pressure is 0.2MPa, the whole process is vacuumed, the vacuum degree is -0.3MPa, the middle layer is aramid pulp, and the adjacent two layers are glued and connected by autoclave;

[0058] The thickness of the upper layer of the upper skin o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com