High-entropy alloy preparation method based on selective laser melting technology

A laser selective melting and high-entropy alloy technology, which is applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the limitations of high-entropy alloy complex structural parts preparation and industrial application, large performance impact, composition segregation, etc. problems, to achieve the effect of excellent comprehensive mechanical properties, high material utilization rate and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

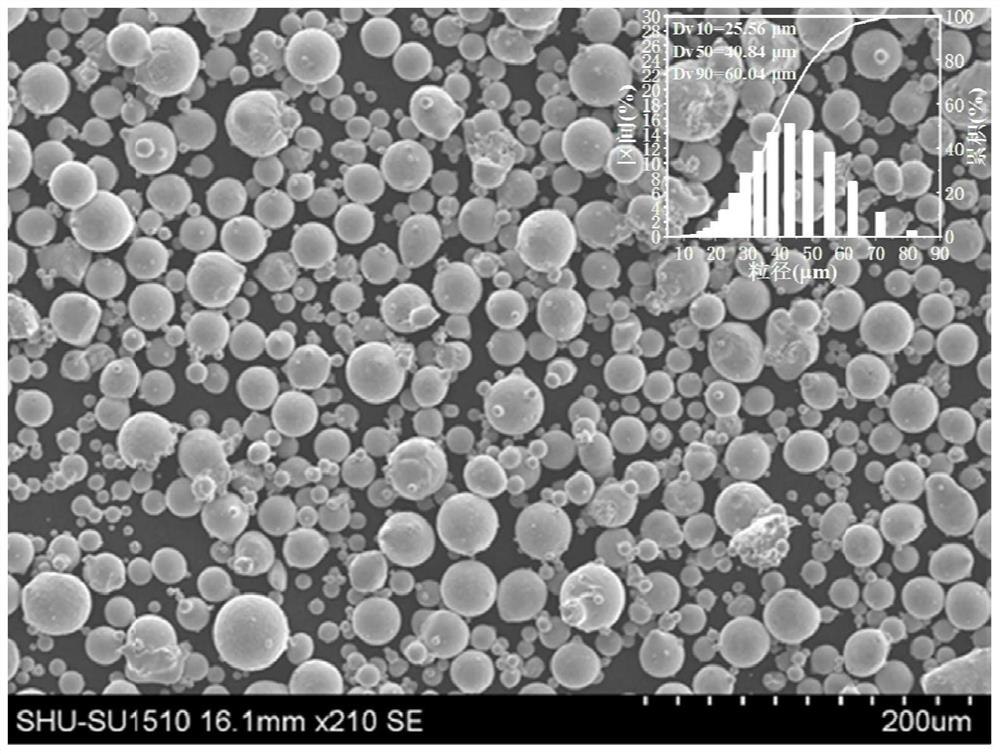

[0049] In the atomization equipment, a high-speed inert gas argon gas flow is used to impact the pre-alloyed (FeCoNi) in a molten state 86 al 7 Ti 7 High entropy alloy, under the action of gas flow (FeCoNi) 86 al 7 Ti 7 The high-entropy alloy metal liquid is broken into metal droplets and sprayed, and under the physical action of the liquid surface tension, a small-sized and round-shaped melt is gradually formed, and then spherical or nearly spherical (FeCoNi) is obtained after cooling and solidification. 86 al 7 Ti 7 High entropy alloy powder.

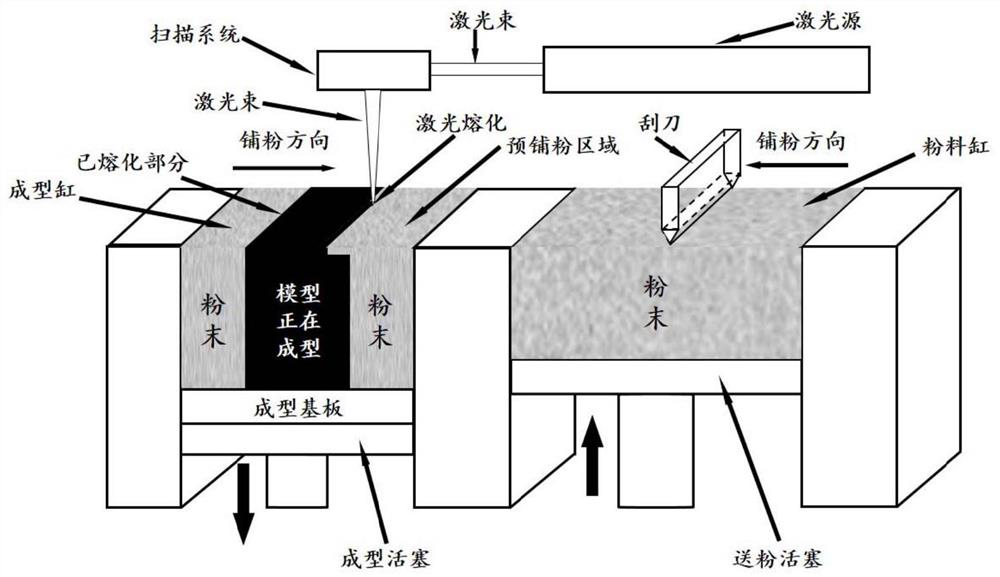

[0050] Use the computer-aided 3D design software Solidworks to carry out the 3D design of the parts and create and output STL format files. The size of the block is 10mm×10mm×10mm and the tensile sample of the standard size is used. The slicing software Magics is used to slice the 3D part data. And output the CLI format file, use the RP64 software to fill the laser scanning path planning of the slice file and convert it into an...

Embodiment 5

[0055] The difference from Example 1 is that a heat treatment equipment is used to heat-treat the high-entropy alloy obtained with a predetermined size, wherein the heat treatment equipment is a muffle furnace, the heat treatment temperature is 780°C, the heat treatment time is 4h, and water quenching. The specific parameters are as follows Table 1.

[0056] For (FeCoNi) prepared by gas atomization technology 86 al 7 Ti 7 The high-entropy alloy powders were dried and scanned by a tungsten filament microscope to obtain the surface morphology of the powders, such as figure 1 shown.

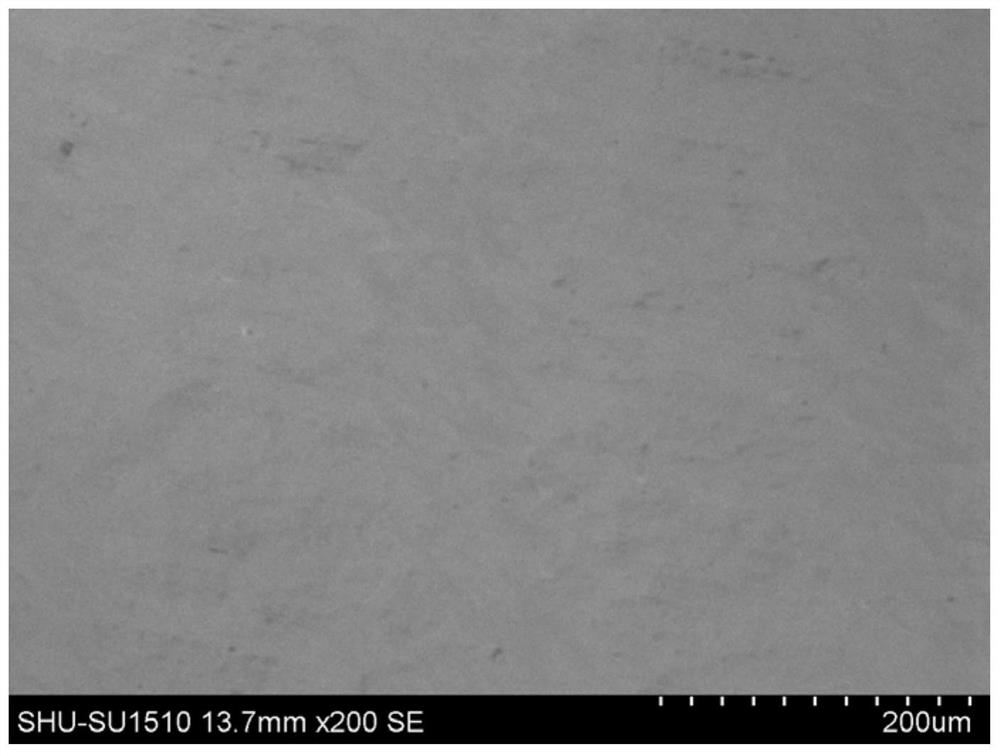

[0057] The high-entropy alloy sample prepared based on laser selective melting technology was polished and scanned by a tungsten filament microscope to obtain the surface morphology of the sample, such as image 3 shown.

[0058] Tensile tests were carried out on tensile samples of standard dimensions of high-entropy alloys prepared with different parameters and before and after heat treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com