Superconducting tunnel junction, superconducting electronic component and preparation method thereof

A tunnel junction and superconducting technology, which is applied in the manufacture/processing of superconductor components and superconductor devices, can solve problems such as inability to meet the requirements for the use of ultra-high frequency oscillators, low resonance frequency, and inability to meet application requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

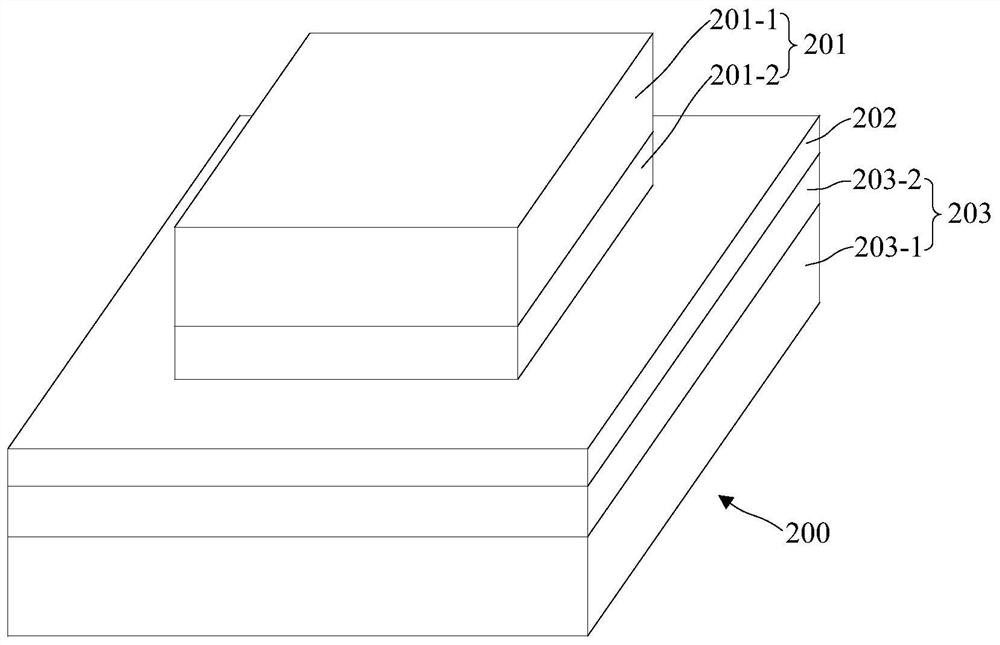

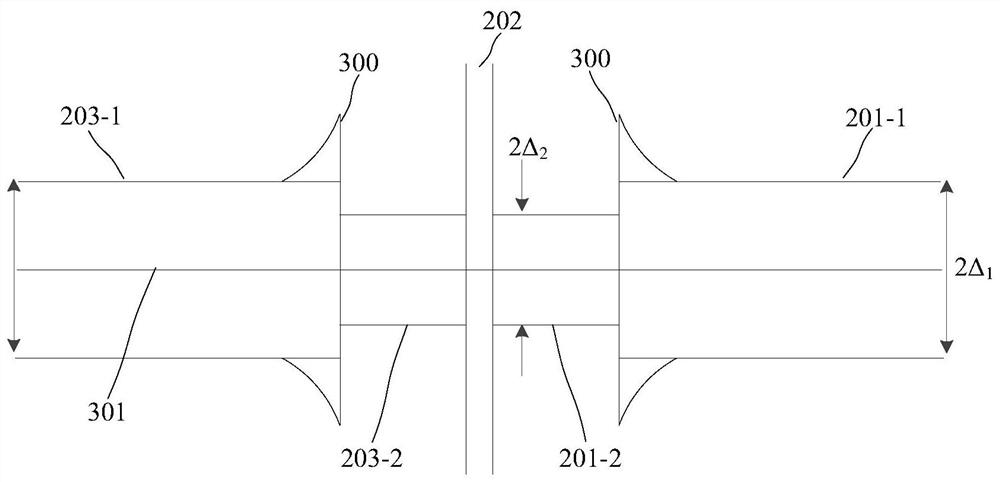

[0079] This embodiment provides a superconducting tunnel junction, such as figure 2 As shown, the superconducting tunnel junction 200 includes a lower electrode 203 , a dielectric layer 202 formed on the lower electrode 203 , and an upper electrode 201 formed on the dielectric layer 202 . Both the upper electrode 201 and the lower electrode 203 include a multilayer structure, the multilayer structure includes layers of different superconducting materials, the superconducting tunnel junction forms a heterogeneous superconducting tunnel junction, and from the dielectric layer to the direction of the upper electrode and the lower electrode, i.e. figure 2 In the direction of the arrow R shown, the energy band widths of the different superconducting materials of the multilayer structure gradually increase.

[0080] In a preferred embodiment of this embodiment, as figure 2 As shown, both the upper electrode 201 and the lower electrode 203 include a two-layer structure. Specifi...

Embodiment 2

[0090] This embodiment provides a superconducting electronic element, such as Figure 5 As shown, the superconducting electronic element 400 includes a substrate 401 and at least one superconducting tunnel junction 402 formed on the substrate 401 (for convenience of illustration, Figure 5 Only one of the superconducting tunnel junctions is shown). At least one superconducting tunnel junction is electrically connected in series and / or in parallel.

[0091] The substrate 401 may be a commonly used substrate such as single crystal silicon, sapphire, silicon carbide, silicon dioxide on single crystal silicon, and the like. The thickness of the substrate 401 can be between 0.2mm-0.7mm, and of course the thickness of the substrate 401 can be selected according to actual needs.

[0092] The superconducting tunnel junction 402 includes a lower electrode 402-1, a dielectric layer 402-2 formed on the lower electrode, and an upper electrode 402-3 formed on the dielectric layer 402-2. ...

Embodiment 3

[0097] This embodiment provides a method for preparing a superconducting electronic element, such as Figure 8 As shown, the method includes the following steps:

[0098] providing a substrate on which a patterned masking layer is formed;

[0099] forming a lower electrode on the substrate through the patterned mask layer;

[0100] forming a dielectric layer on the lower electrode;

[0101] forming an upper electrode on the dielectric layer;

[0102] Wherein, the upper electrode and the lower electrode include a superconducting material, the upper electrode, the dielectric layer, and the lower electrode form a superconducting tunnel junction, and both the upper electrode and the lower electrode include a multi- a layer structure, the multilayer structure includes layers of different superconducting materials, and in the direction from the dielectric layer to the upper electrode and the lower electrode, the different superconducting materials of the multilayer structure The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com