Ultralow-demagnetization-rate high-temperature samarium-cobalt permanent magnet material and preparation method thereof

A permanent magnet material, high temperature technology, used in magnetic materials, permanent magnet manufacturing, inductor/transformer/magnet manufacturing, etc., can solve problems such as poor high temperature stability and high high temperature demagnetization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

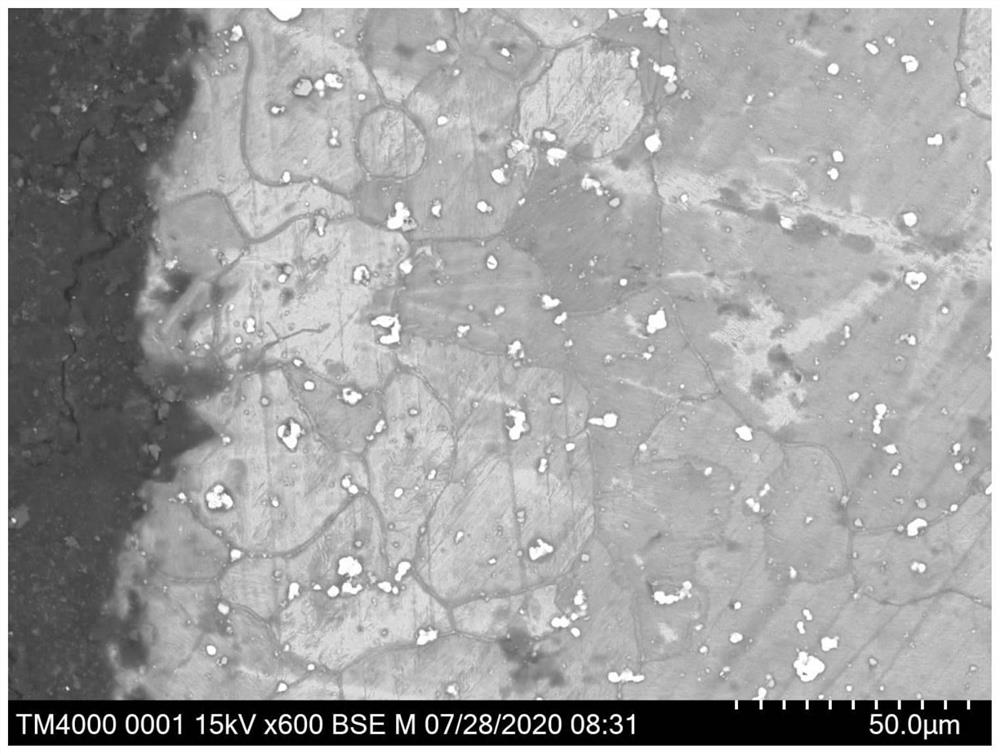

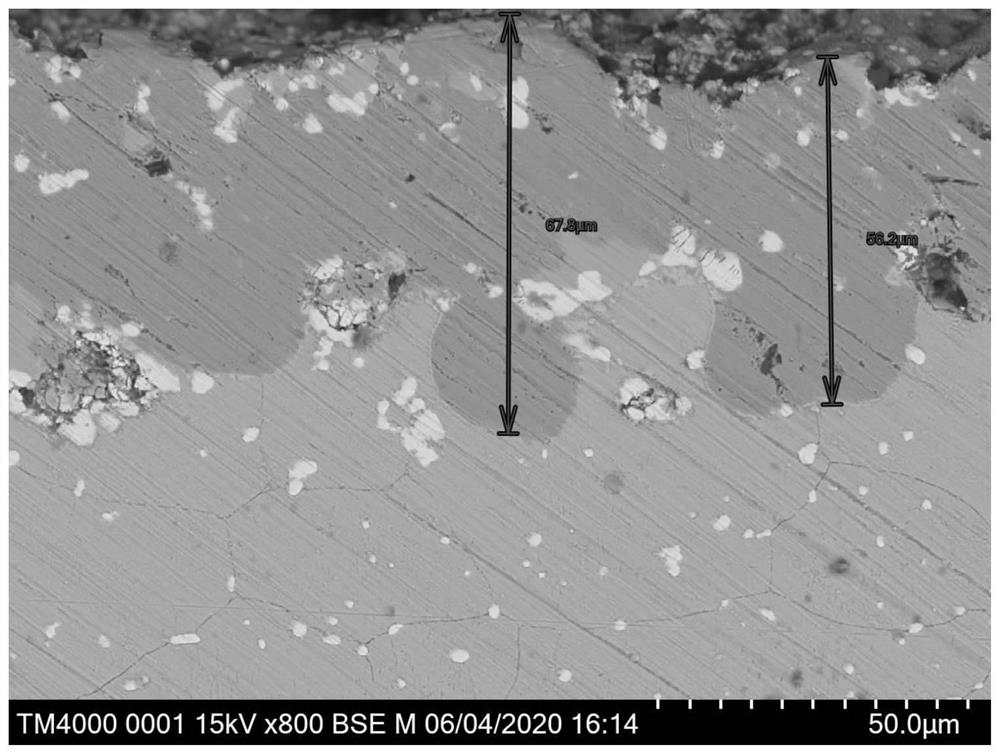

Image

Examples

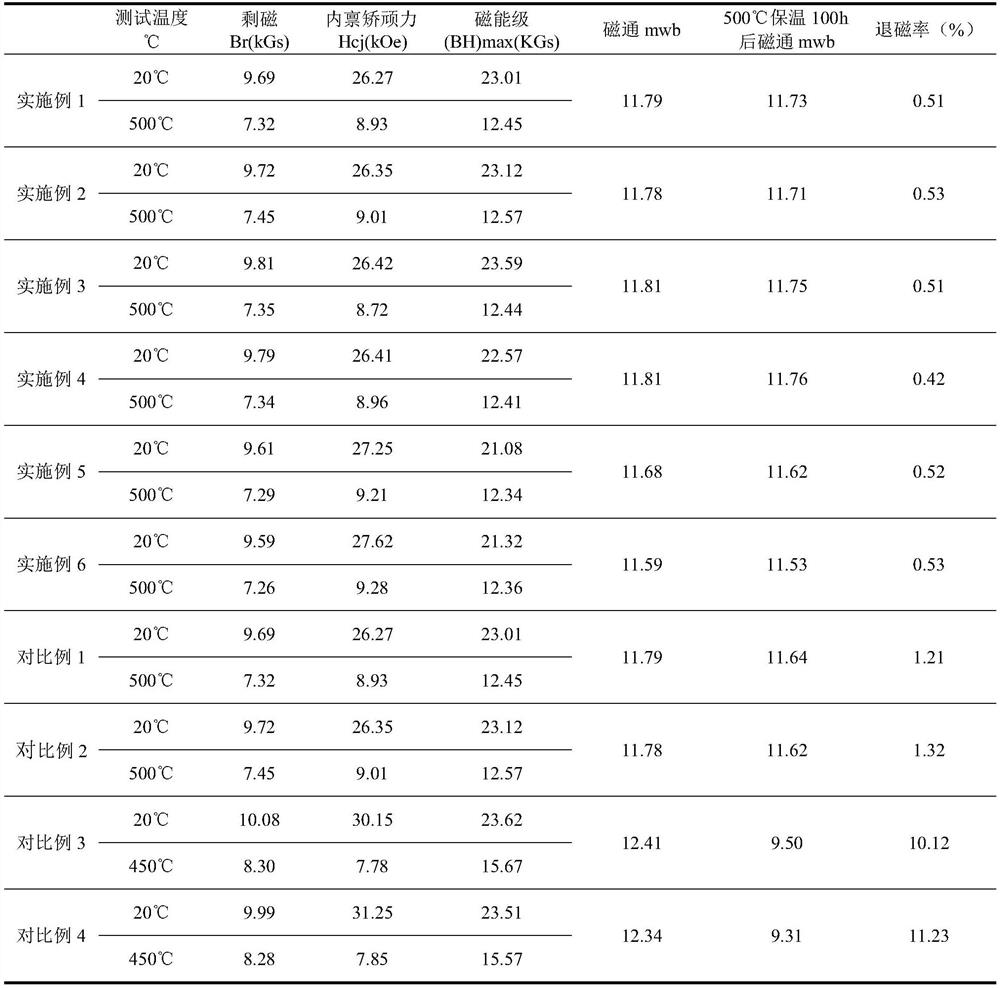

Embodiment 1

[0034] A samarium-cobalt permanent magnet material for high temperature with ultra-low demagnetization rate, the chemical atomic measurement formula of the samarium-cobalt permanent magnet material is Sm(Co 1-x-y-v Fe x Cu y Zr v ) z , where x=0.10, y=0.13, v=0.034, z=8.0.

[0035] The preparation method of the samarium cobalt permanent magnet material comprises the following steps:

[0036] Step 1: Ingredients and Melting

[0037] Sm with a purity of 99.95%, Co with a purity of 99.98%, Cu with a purity of 99.99%, Fe with a purity of 99.9%, and Zr with a purity of 99.99% are mixed according to the proportion, and the raw materials are put into a vacuum induction melting furnace, and the Sm is placed at the bottom of the vacuum induction melting furnace to reduce the volatilization of Sm during the smelting process, first vacuumize to 3×10 -3 After Pa, fill it with argon to keep the vacuum at -0.05MPa, and melt it under the conditions of working voltage of 45V and working...

Embodiment 2

[0051] A samarium-cobalt permanent magnet material for high temperature with ultra-low demagnetization rate, the chemical atomic measurement formula of the samarium-cobalt permanent magnet material is Sm(Co 1-x-y-v Fe x Cu y Zr v ) z , where x=0.10, y=0.13, v=0.034, z=8.0.

[0052] The preparation method of the samarium cobalt permanent magnet material comprises the following steps:

[0053] Step 1: Ingredients and Melting

[0054] Sm with a purity of 99.95%, Co with a purity of 99.98%, Cu with a purity of 99.99%, Fe with a purity of 99.9%, and Zr with a purity of 99.99% are mixed according to the proportion, and the raw materials are put into a vacuum induction melting furnace, and the Sm is placed at the bottom of the vacuum induction melting furnace to reduce the volatilization of Sm during the smelting process, first vacuumize to 3×10 -3 After Pa, fill it with argon to keep the vacuum at -0.05MPa, and melt it under the conditions of working voltage of 45V and working...

Embodiment 3

[0067] A samarium-cobalt permanent magnet material for high temperature with ultra-low demagnetization rate, the chemical atomic measurement formula of the samarium-cobalt permanent magnet material is Sm(Co 1-x-y-v Fe x Cu y Zr v ) z , where x=0.13, y=0.13, v=0.038, z=8.1.

[0068] The preparation method of the samarium cobalt permanent magnet material comprises the following steps:

[0069] Step 1: Ingredients and Melting

[0070] Sm with a purity of 99.95%, Co with a purity of 99.98%, Cu with a purity of 99.99%, Fe with a purity of 99.9%, and Zr with a purity of 99.99% are mixed according to the proportion, and the raw materials are put into a vacuum induction melting furnace, and the Sm is placed at the bottom of the vacuum induction melting furnace to reduce the volatilization of Sm during the smelting process, first vacuumize to 3×10 -3 After Pa, fill it with argon to keep the vacuum at -0.05MPa, and melt it under the conditions of working voltage of 45V and working...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com