Micro-disturbance cutting-free blasting method

A micro-disturbance, micro-difference initiation technology, used in blasting, earth-moving drilling, surface mining, etc., can solve the problem of inefficient and low-cost solution to weak, broken, narrow ore vein mining, etc., to reduce the amount of construction and explosives. consumption, reduce difficulty and cost, and reduce the amount of drilling construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A micro-disturbance non-cutting blasting method, which is used for access mining of weak and broken narrow veins, comprising the following steps:

[0035] S1: Determine the position of the main weak structural surface 5 of the face through measurement and data analysis.

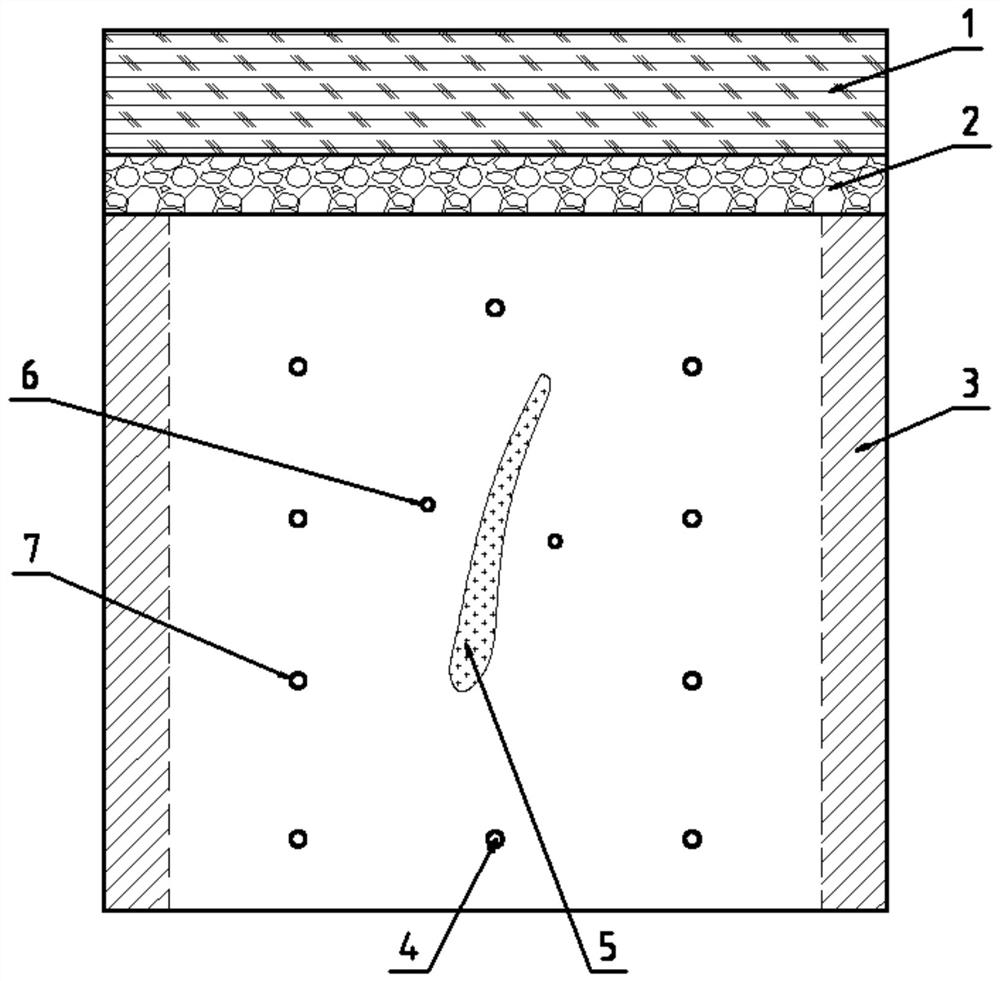

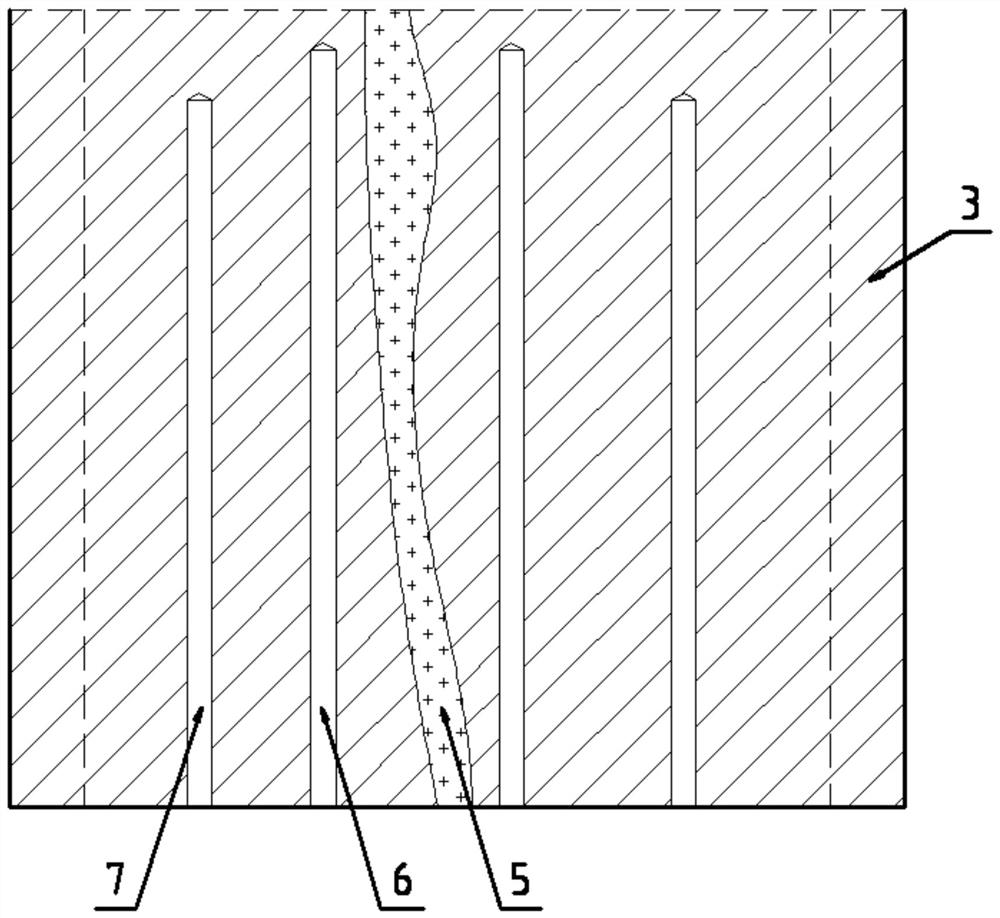

[0036] When drilling rock, according to the development of the face joint fissure surface, look for the main weak structural surface 5. Such as Figure 1-2 As shown, the weak structure surface 5 is an inclined strip-shaped surface located in the middle of the palm surface. Use a compass and tape measure to measure the position of the main weak structural surface 5 of the palm face, and measure the tendency of the weak structural surface 5 through the compass, and obtain the direction of the weak structural surface 5 after adding and subtracting 90°.

[0037] S2: Drill a slotted hole 6 on both sides of the weak structural surface 5, and drill peripheral holes 7 around the face of the tunnel.

[0038]...

Embodiment 2

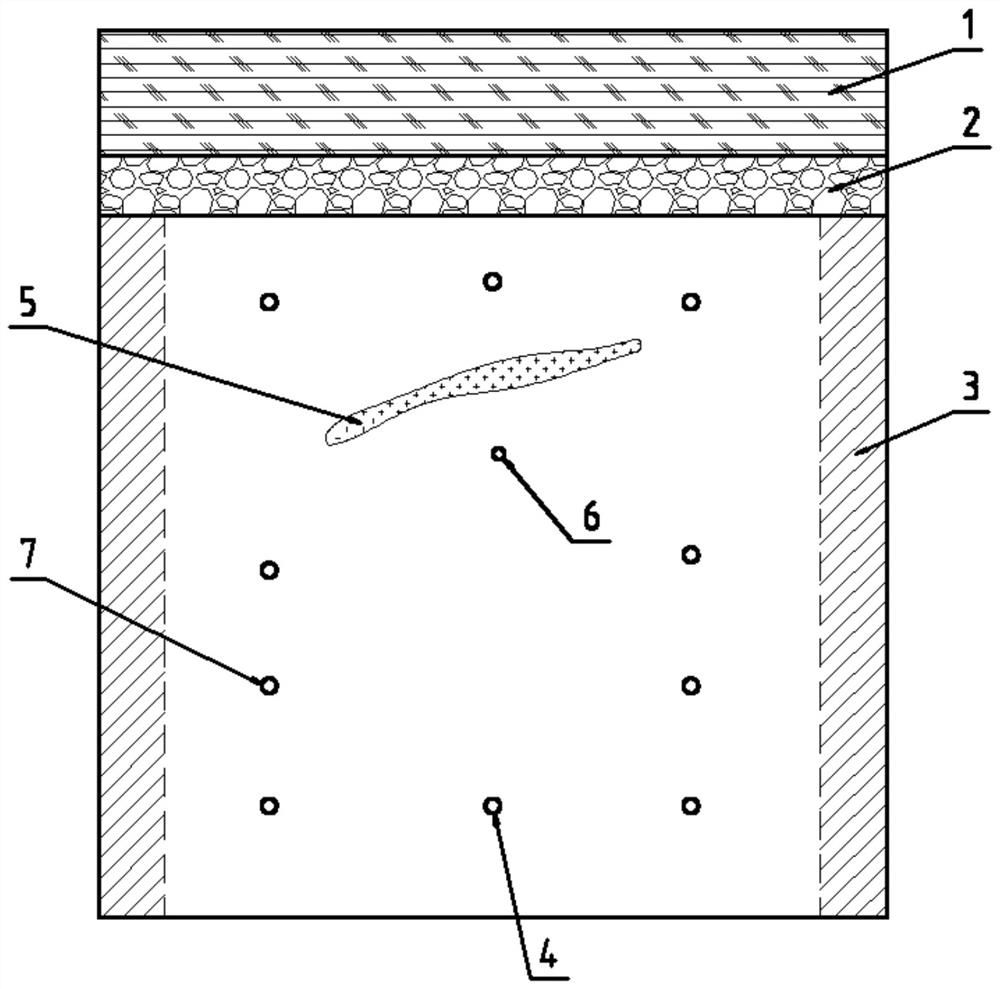

[0048] S1: Determine the position of the main weak structural surface 5 of the face through measurement and data analysis.

[0049] When drilling rock, according to the development of the face joint fissure surface, look for the main weak structural surface 5. Such as image 3As shown, the weak structural surface 5 is a nearly horizontal inclined strip-shaped surface, which is close to the top of the palm face. Use a compass and tape measure to measure the position of the main weak structural surface 5 of the palm face, and measure the tendency of the weak structural surface 5 through the compass, and obtain the direction of the weak structural surface 5 after adding and subtracting 90°.

[0050] S2: Dig a slotted hole 6 at the inner side of the weak structural surface 5 near the center of the palm face, and dig a peripheral hole 7 around the face of the palm.

[0051] In this embodiment, according to the size of the tunnel face and the development of the weak structural sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com