Oxygen production humidity control type air conditioning system

An air-conditioning system and wet technology, which is applied in the field of oxygen-controlling and humidity-controlling air-conditioning systems, can solve problems such as water leakage and water seepage on external walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

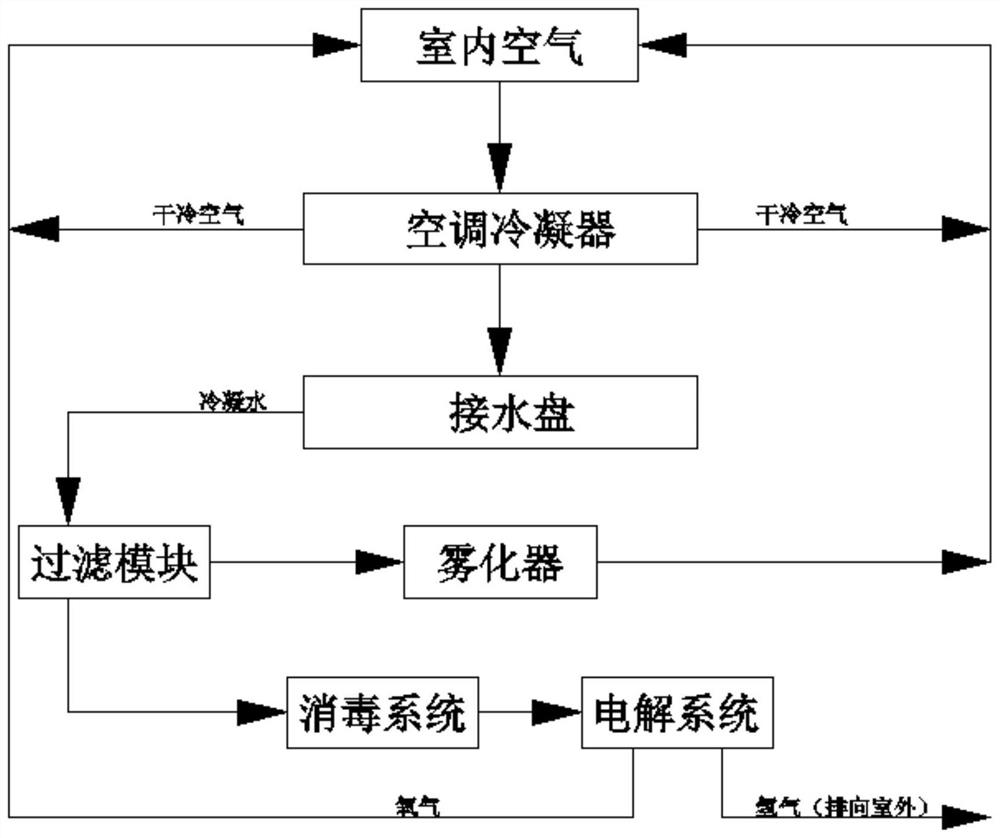

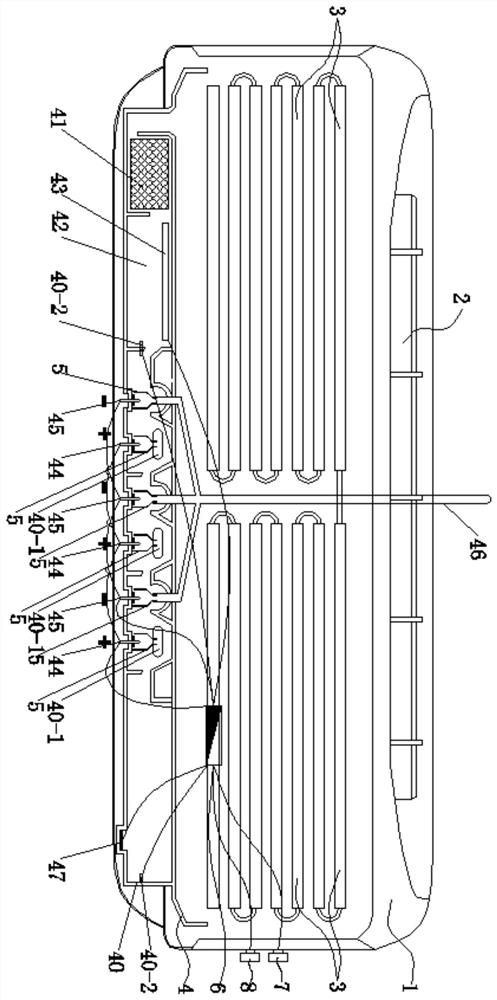

[0026] In this oxygen generation and humidity control air-conditioning system, the indoor air circulates continuously and passes through the cooling fins of the condenser. When the water molecules in the air are cooled, they form liquid water that attaches to the cooling fins of the condenser, and then flows to the water tray below. Then it flows into the position of the filter system through the end of the water tray tank, and is filtered through layers of filter screen, non-woven fabric and semi-permeable membrane in the filter system to filter out the dust in the condensed liquid water, and then enters the water storage In the area, the ultraviolet C (UVC) produced by the ultraviolet germicidal lamp above the water storage area irradiates liquid water. When bacteria, viruses, algae and other organisms in the liquid water are irradiated by a certain dose of UVC (wavelength 254nm), the DNA of their cells , The RNA structure is destroyed, the cells cannot be regenerated, and th...

Embodiment 2

[0041] On the basis of Embodiment 1, when the humidity value of the indoor air is lower than the critical value, the humidity sensor detects a signal to the controller, and the water level sensor 40-2 detects that there is water in the water storage area, and the controller controls the ultrasonic electronic atomization The device is energized to atomize the liquid water to humidify the indoor air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com