Novel glass fiber reinforced plastic lining concrete combined pipe

A technology that is lined with concrete and glass fiber reinforced plastics, applied in the field of pipelines, can solve problems such as heat dissipation, cracked pipelines, and antifreeze problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

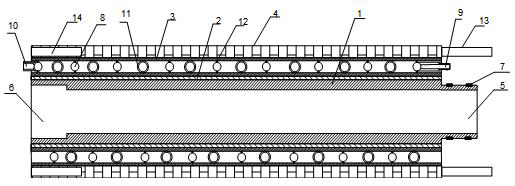

[0021] like figure 1 As shown in the figure, the novel FRP lined concrete composite pipe includes a FRP inner lining layer 1, an elastic interface layer 2, a functional layer 3 and a concrete layer 4 sequentially arranged from the inside to the outside.

[0022] The elastic interface layer 2 is a material with elasticity and a relatively large friction coefficient, such as resin or the like. The frictional force of the elastic interface layer 2 is relatively large, which prevents displacement of the FRP inner lining layer 1 , the functional layer 3 and the concrete layer 4 .

[0023] Further, one end of the FRP lining pipe is provided with a socket 5 , the other end of the FRP lining pipe is provided with a socket 6 , and a groove mounting sealing ring 7 is provided on the socket 5 . The connection of the two combined pipes is realized by a traditional plug-in method. Since it is the prior art, this embodiment will not describe in detail.

[0024] It is worth emphasizing tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com