Electroplating solution for directly electrodepositing iron on surface of magnesium alloy and electroplating process thereof

A magnesium alloy and electrodeposition technology, which is applied in the field of surface engineering and surface treatment, can solve the problems of depositing pure iron coating, etc., and achieve the effect of promoting deposition reaction, realizing coating morphology and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The electroplating solution that can be used for direct electrodepositing iron on the surface of magnesium alloy of the present invention and electroplating process concrete operating steps thereof are as follows:

[0046] (1) ultrasonically clean the magnesium alloy to be plated in acetone solution for 8 minutes, and then rinse with deionized water;

[0047] (2) Use 25 at.% phosphoric acid aqueous solution to derust the substrate for 10 seconds, and then rinse with deionized water;

[0048] (3) Preparation of electroplating solution: mix ferrous sulfate 56g / L, sodium citrate 294g / L, sodium fluoride 10g / L, sodium lauryl sulfate 0.01g / L, and sodium pyrophosphate 0.1g / L. It can be prepared as a plating solution, the solvent is deionized water, and the pH is adjusted to 6-8 by ammonia water 20mL / L;

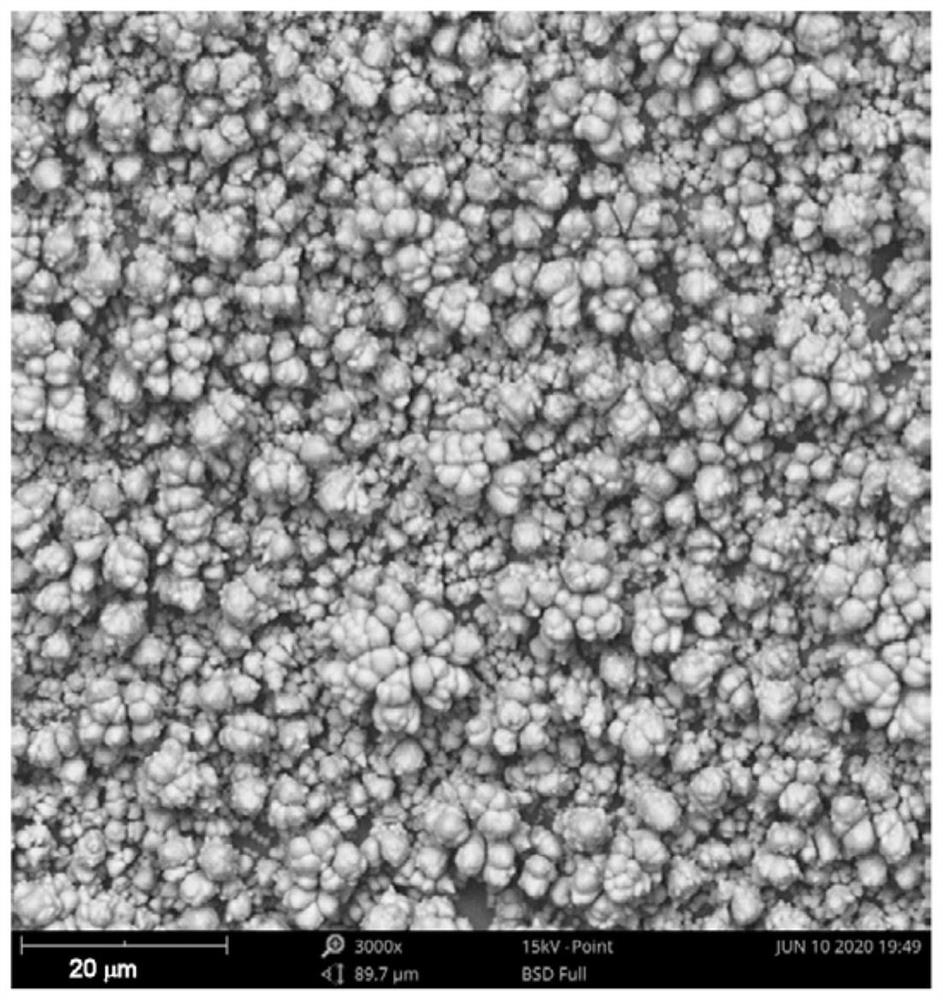

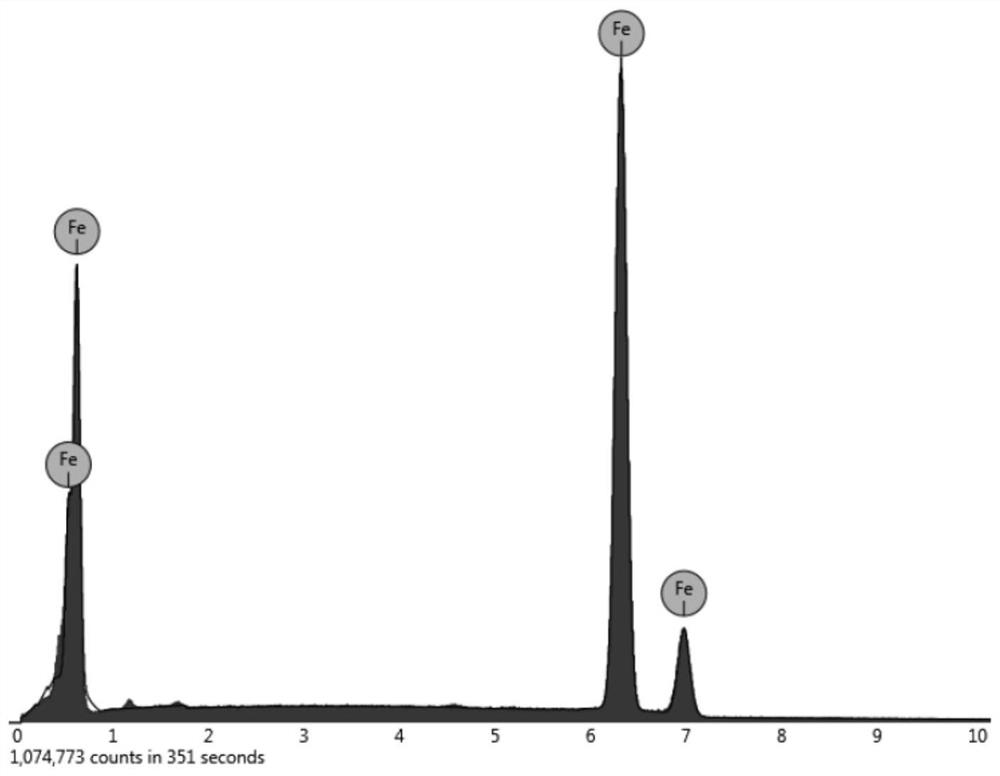

[0049] (4) Put the magnesium alloy of step (2) into the electroplating solution obtained in step (3) for electrodeposition (the anode is ruthenium titanium iridium), then cle...

Embodiment 2

[0051] The electroplating solution that can be used for direct electrodepositing iron on the surface of magnesium alloy of the present invention and electroplating process concrete operating steps thereof are as follows:

[0052] (1) ultrasonically clean the magnesium alloy to be plated in acetone solution for 8 minutes, and then rinse with deionized water;

[0053] (2) Use 25 at.% phosphoric acid aqueous solution to derust the substrate for 10 seconds, and then rinse with deionized water;

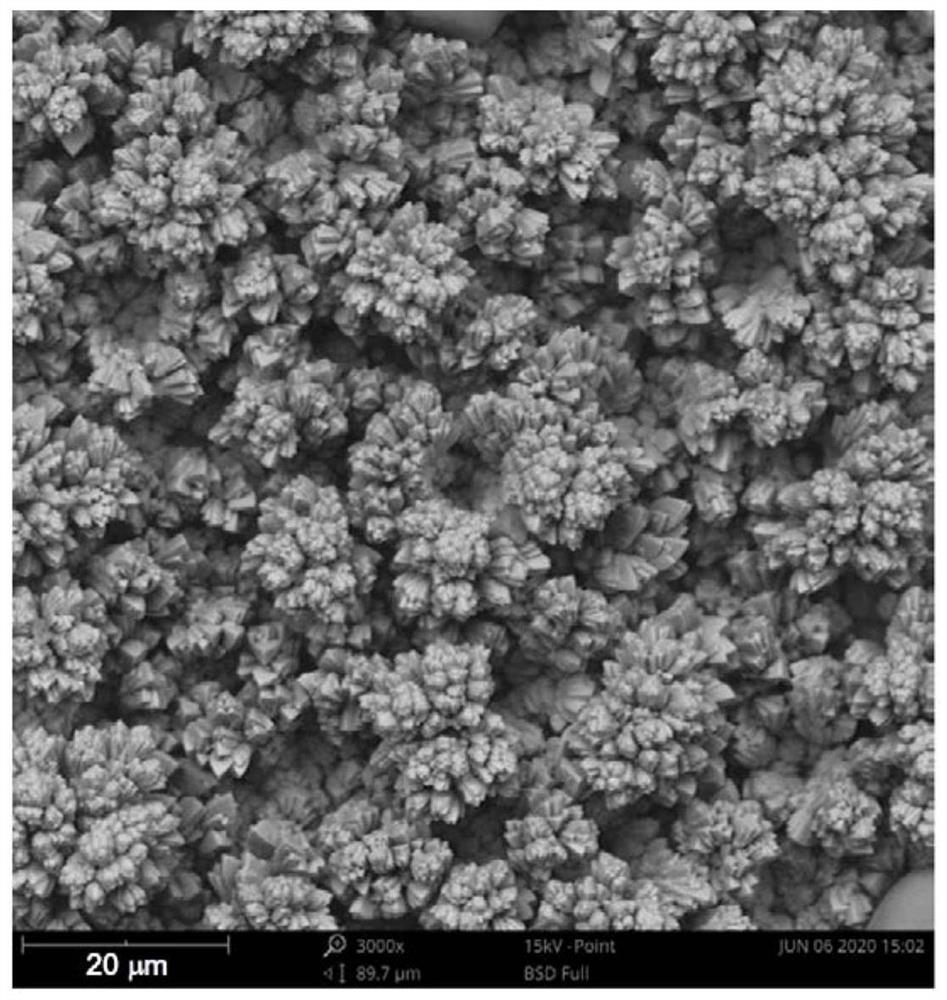

[0054] (3) Preparation of electroplating solution: mix ferrous sulfate 56g / L, sodium citrate 294g / L, sodium fluoride 10g / L, sodium lauryl sulfate 0.1g / L, and sodium pyrophosphate 30g / L Prepare a plating solution, the solvent is deionized water, adjust the pH to 6-8 with 20mL / L of ammonia water;

[0055] (4) Put the magnesium alloy of step (2) into the electroplating solution obtained in step (3) for electrodeposition (the anode is ruthenium titanium iridium), then clean and dry with deion...

Embodiment 3

[0060] The electroplating solution that can be used for direct electrodepositing iron on the surface of magnesium alloy of the present invention and electroplating process concrete operating steps thereof are as follows:

[0061] (1) ultrasonically clean the magnesium alloy to be plated in acetone solution for 8 minutes, and then rinse with deionized water;

[0062] (2) Use 25 at.% phosphoric acid aqueous solution to derust the substrate for 10 seconds, and then rinse with deionized water;

[0063] (3) Preparation of electroplating solution: mix ferrous sulfate 56g / L, sodium citrate 147g / L, sodium fluoride 10g / L, sodium lauryl sulfate 0.1g / L, and sodium pyrophosphate 20g / L Prepare a plating solution, the solvent is deionized water, adjust the pH to 6-8 with 20mL / L of ammonia water;

[0064] (4) Put the magnesium alloy of step (2) into the electroplating solution obtained in step (3) for electrodeposition (the anode is ruthenium titanium iridium), then clean and dry with deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com