Energy storage polymer composite film based on inorganic insulating layer modification and preparation method thereof

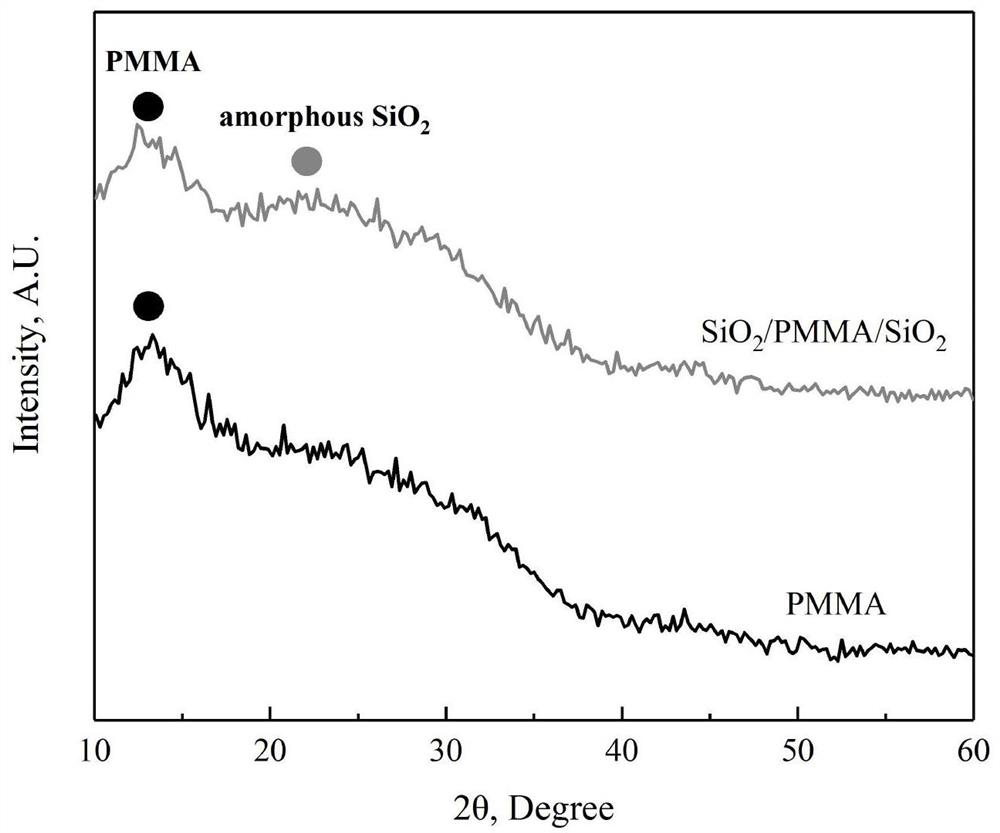

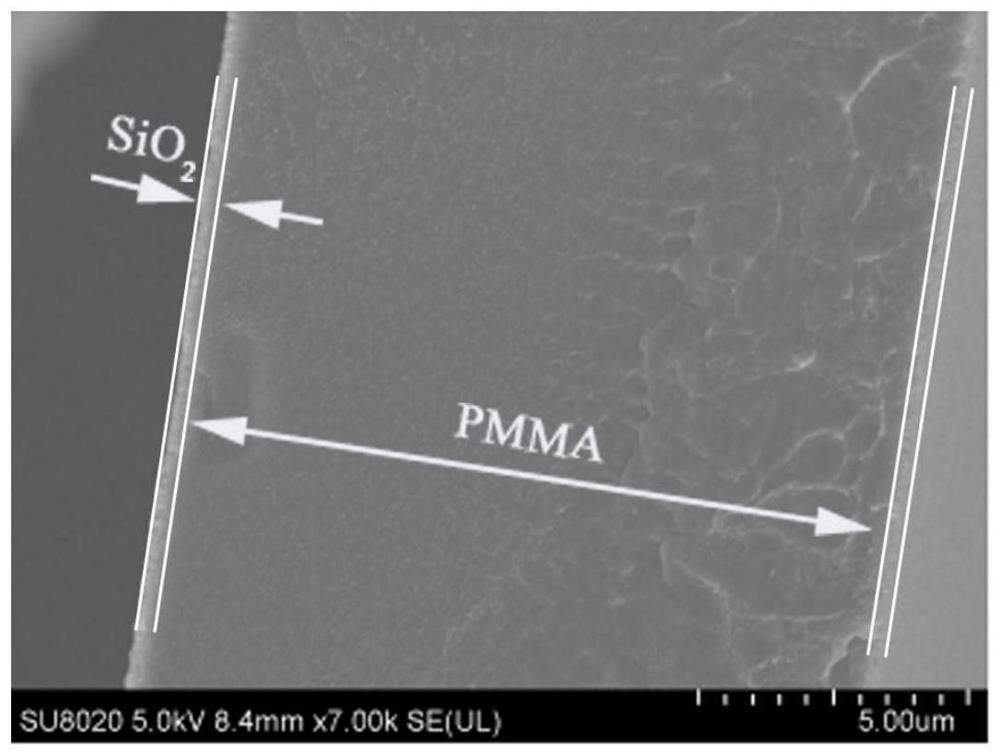

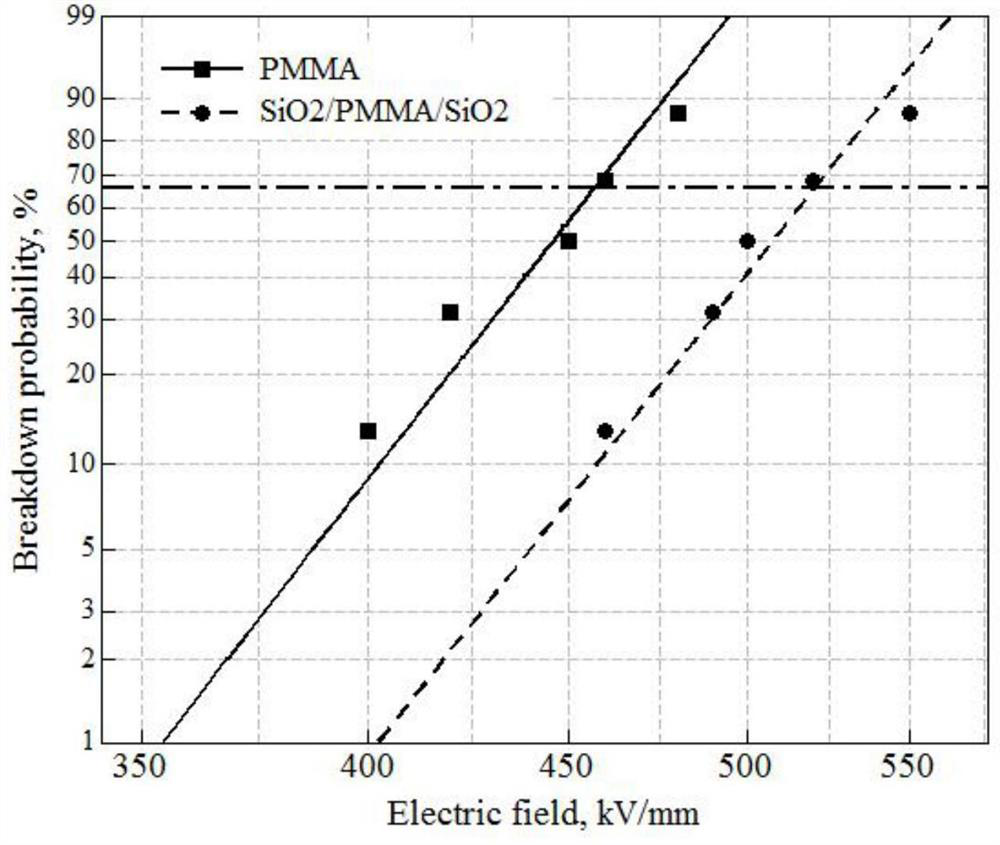

A technology of inorganic insulating layer and composite film, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of low energy storage performance and poor breakdown characteristics of polymer medium, and achieve energy storage performance and the effects of excellent breakdown characteristics, reduced electrical conductivity, and high polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] A method for preparing an energy storage polymer composite film based on the modification of an inorganic insulating layer includes the following steps:

[0034] Step 1. Weigh the PMMA and DMF solutions according to the material-to-liquid ratio, put the weighed PMMA into a vacuum oven for drying, take it out and slowly add it to the DMF solution under heating and stirring conditions, and then let it stand to room temperature , And then stir at room temperature to prepare PMMA colloid, set aside;

[0035] Step 2. Put the PMMA colloid obtained in step 1 under vacuum conditions and let it stand to eliminate air bubbles, then pour the PMMA colloid onto a clean glass substrate, scrape coating to obtain a wet film on the glass substrate, and place it in a drying oven for drying , Get dry film;

[0036] Step 3. Transfer the glass substrate with the dry film obtained in step 2 to a vacuum drying box for vacuum drying, take it out and cool to room temperature, then put it in clean wat...

specific Embodiment approach 2

[0054] A method for preparing an energy storage polymer composite film based on the modification of an inorganic insulating layer includes the following steps:

[0055] Step 1. Weigh the PMMA and DMF solutions according to the material-to-liquid ratio, put the weighed PMMA into a vacuum oven for drying, take it out and slowly add it to the DMF solution under heating and stirring conditions, and then let it stand to room temperature , And then stir at room temperature to prepare PMMA colloid, set aside;

[0056] Step 2. Put the PMMA colloid obtained in step 1 under vacuum conditions and let it stand to eliminate air bubbles, then pour the PMMA colloid onto a clean glass substrate, scrape coating to obtain a wet film on the glass substrate, and place it in a drying oven for drying , Get dry film;

[0057] Step 3. Transfer the glass substrate with the dry film obtained in step 2 to a vacuum drying box for vacuum drying, take it out and cool to room temperature, then put it in clean wat...

specific Embodiment approach 3

[0071] A method for preparing an energy storage polymer composite film based on the modification of an inorganic insulating layer includes the following steps:

[0072] Step 1. Weigh the PMMA and DMF solutions according to the material-to-liquid ratio, put the weighed PMMA into a vacuum oven for drying, take it out and slowly add it to the DMF solution under heating and stirring conditions, and then let it stand to room temperature , And then stirred at room temperature to prepare PMMA colloid, ready for use;

[0073] Step 2. Put the PMMA colloid obtained in step 1 under vacuum conditions and let it stand to eliminate air bubbles, then pour the PMMA colloid onto a clean glass substrate, scrape the wet film on the glass substrate and place it in a drying oven for drying , Get dry film;

[0074] Step 3. Transfer the glass substrate with the dry film obtained in step 2 to a vacuum drying box for vacuum drying, take it out and cool to room temperature, then put it in clean water and pee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com