Method for extracting cannabidiol from cannabis

A cannabidiol and cannabis technology, applied in the field of medicine, can solve problems such as high loss and low efficiency, and achieve the effects of high crystallization efficiency, improved yield and extended range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

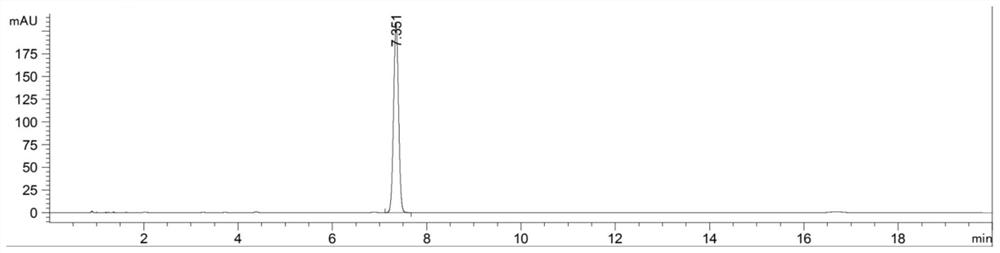

[0103] The preparation of embodiment 1 cannabidiol

[0104] The embodiment part provides that the method of the present invention is used to prepare cannabidiol under different technical parameters. 600 kg, no further description below.

[0105] 1) Pulverize the whole plant of industrial hemp, pass it through an 80-mesh sieve, and obtain medicinal material powder, and its moisture content is measured to be 13.6%;

[0106] 2) The above medicinal material powder was reflux extracted 3 times with 4 times the amount of 30% (V / V) ethanol, each time for 0.5h, to obtain an extract;

[0107] 3) When the above extract (-0.08Mpa, 60°C) was concentrated under reduced pressure to 50°C, the relative density measured was 1.05, and 1 / 10 times the amount of purified water was added to the medicinal material, and concentrated at normal pressure for 1.5h (94°C) to obtain a stream paste;

[0108] 4) Disperse the above liquid ointment with 1 times the amount of purified water, adjust the pH to...

Embodiment 2

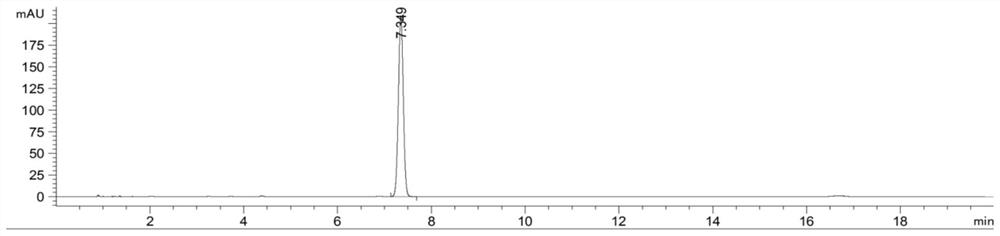

[0115] Embodiment 2: the preparation of cannabidiol

[0116] 1) crushing the flowers and leaves of industrial hemp, and passing through a 40-mesh sieve to obtain medicinal material powder, and its moisture content was measured to be 14.2%;

[0117] 2) Ultrasonic-assisted extraction of the above-mentioned medicinal material powder with 5 times the amount of 70% (V / V) ethanol for 0.5 hours each time to obtain an extract;

[0118] 3) Concentrate the above extract (-0.80Mpa, 65°C) under reduced pressure to 50°C, and the measured relative density is 1.35, add 1 / 20 times the amount of purified water of the medicinal material, concentrate at normal pressure for 1h (94°C), and obtain the extract paste;

[0119] 4) Disperse the above extract with 10 times the amount of purified water, adjust the pH to 2.5 with hydrochloric acid (10mol / L), sink in water at a temperature of 20°C for 4 hours, remove impurities, and obtain a water-sinking liquid;

[0120] 5) Centrifuge the above-mentione...

Embodiment 3

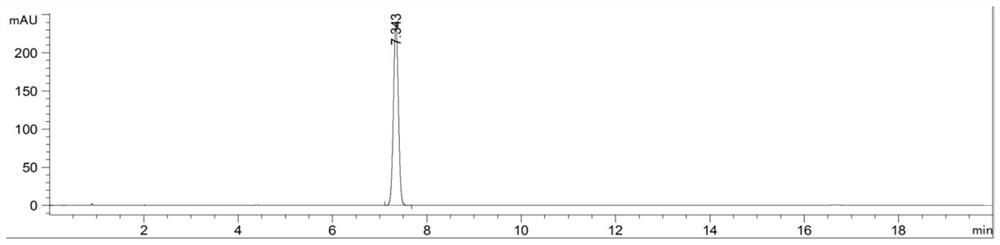

[0127] Embodiment 3: the preparation of cannabidiol

[0128] 1) Pulverize the flowers and leaves of industrial hemp, and pass through a 10-mesh sieve to obtain medicinal material powder, the water content of which is measured to be 15.1%.

[0129] 2) The above-mentioned medicinal material powder was soaked and extracted twice with 10 times the amount of 100% (V / V) ethanol, each time for 2.5 hours, to obtain an extract;

[0130] 3) Concentrate the above extract (-0.80Mpa, 65°C) under reduced pressure to 50°C and measure the relative density to 1.2, add 1 / 100 times the amount of purified water of the medicinal material, boil at normal pressure (94°C) for 1.5h, and obtain the extract paste;

[0131] 4) Disperse the above-mentioned extract with 5 times the amount of purified water, adjust the pH to 6.0 with sulfuric acid (18mol / L), sink in water at a temperature of 10°C for 18 hours, remove impurities, and obtain a water-sinking liquid;

[0132] 5) Centrifuge the above-mentioned w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com