Polyatomic co-doped molybdenum disulfide and preparation method and application thereof

A technology of molybdenum disulfide and atoms, applied in the field of preparation of two-dimensional nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Dissolve 400mg of ammonium molybdate and 359mg of cobalt nitrate in 20mL of water. After ultrasonic dispersion for 1 hour, continue to add 55.5mg of selenium powder. Carbon disulfide was sealed into a 60mL autoclave under the protection of argon.

[0037] 2. Keep the autoclave in (1) at 200°C for 4h.

[0038] 3. the sample obtained in (2) in 6mol L -1 Potassium hydroxide solution for 5h. Then wash with ultrapure water and ethanol and filter with suction.

[0039] 4. Dry the sample obtained in (3) at 80° C. for 12 hours to obtain template-free cobalt-selenium co-doped molybdenum disulfide.

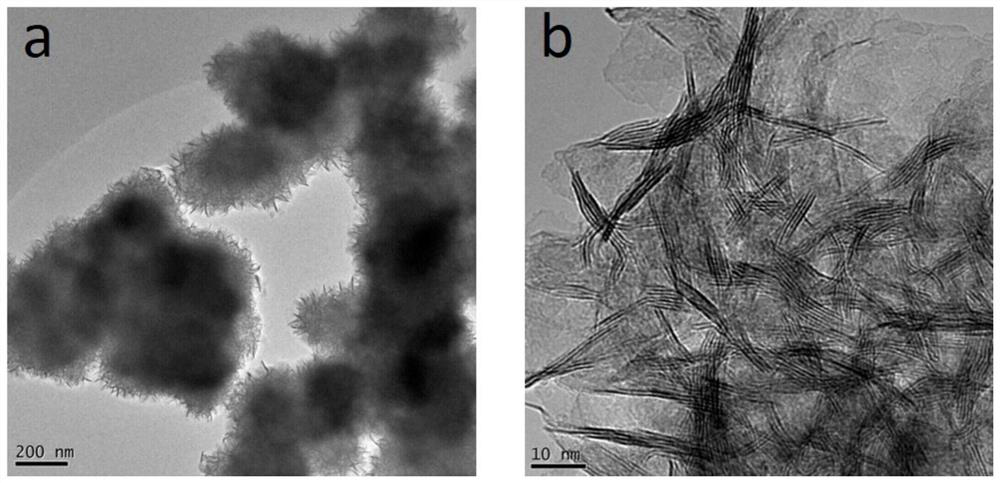

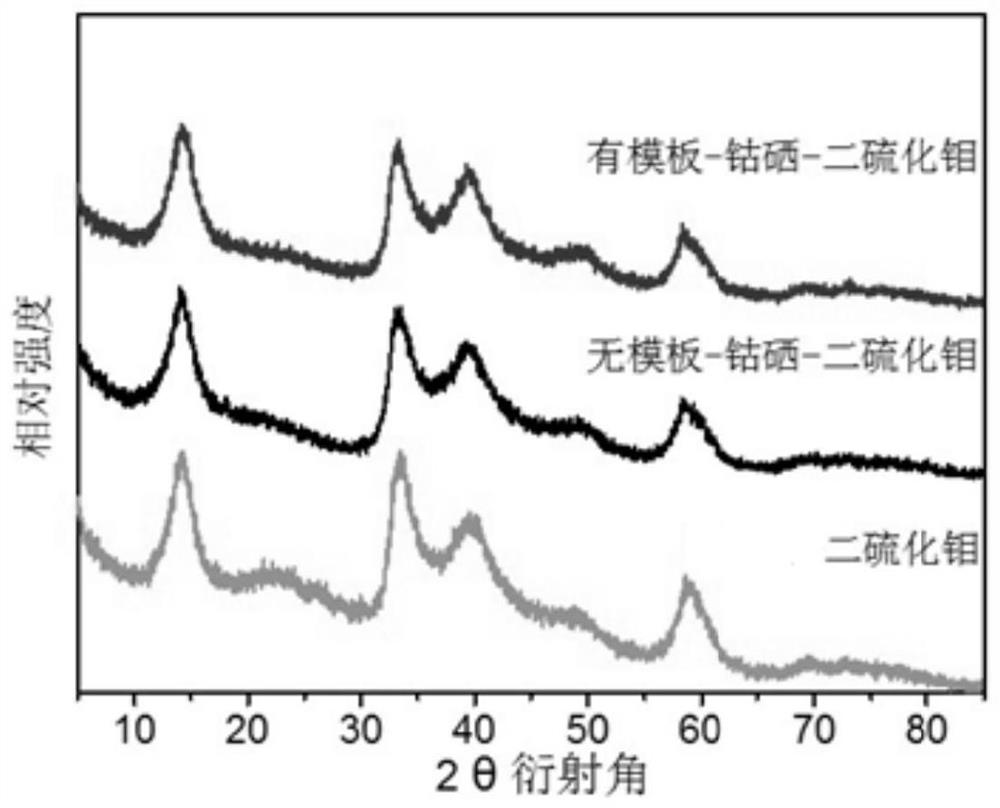

[0040] TEM (see figure 1 a) show that the obtained samples are all flower-like structures, high-resolution electron microscopy (see figure 1b) shows that the obtained sample has a two-dimensional layered structure, and the number of layers is mostly a few layers, and no other clusters or impurity phases appear. X-ray diffraction spectrum (see image 3 ) shows that the obtai...

Embodiment 2

[0042] 1. Put 400mg of ammonium molybdate and 2.5g of silicon dioxide in 20mL of water, ultrasonically disperse for 0.5h, then add 359mg of cobalt nitrate and ultrasonically disperse for 1h, continue to add 55.5mg of selenium powder, after ultrasonically mixing for 1h, stir at 25°C for 12h , dried at 60°C for 12h, and then sealed with 10mL of carbon disulfide in a 60mL autoclave under the protection of argon.

[0043] 2. Keep the autoclave in (1) at 200°C for 4h.

[0044] 3. Treat the sample obtained in (2) with 5% hydrofluoric acid solution for 12 hours. Then wash with ultrapure water and ethanol and filter with suction.

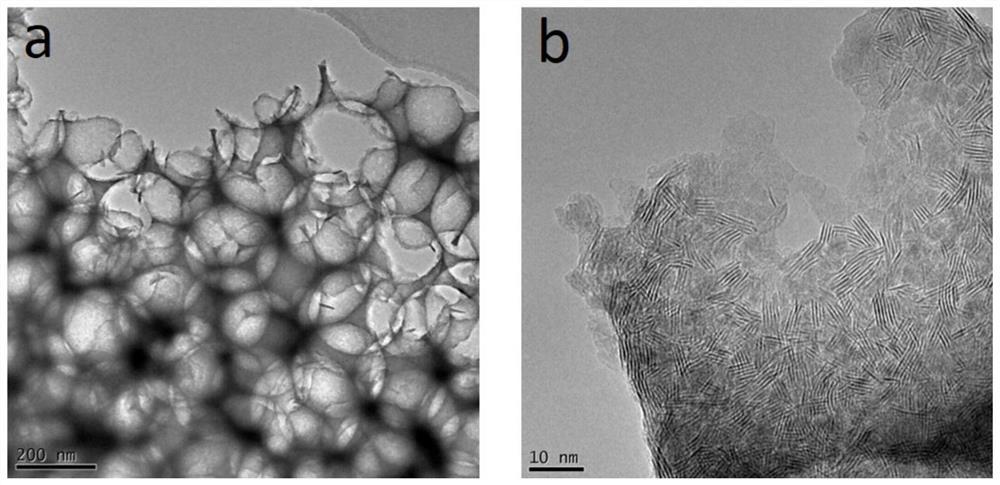

[0045] 4. Dry the sample obtained in (3) at 80° C. for 12 hours to obtain cobalt-selenium co-doped molybdenum disulfide with a template. TEM (see figure 2 a) shows that the obtained samples are all three-dimensional foam-like structures, high-resolution electron microscope (see figure 2 b) It shows that the obtained sample has a two-dimensional layere...

Embodiment 3

[0053] 1. Ultrasonic disperse 400mg ammonium molybdate and 2.5g silicon dioxide in 30mL water for 0.5h, add 159mg cobalt nitrate and 150mg nickel nitrate and ultrasonically disperse for 2h, then stir at 25°C for 12h, dry at 60°C for 12h, and then mix with 10mL of carbon disulfide was sealed into a 60mL autoclave under the protection of argon.

[0054] 2. Keep the autoclave in (1) at 400°C for 4h.

[0055] 3. Treat the sample obtained in (2) with 5% hydrofluoric acid solution for 12 hours. Then wash with ultrapure water and ethanol and filter with suction.

[0056] 4. Dry the sample obtained in (3) at 80° C. for 12 hours to obtain templated cobalt-nickel co-doped molybdenum disulfide.

[0057] The transmission electron microscope showed that the obtained sample had a three-dimensional foam-like structure, and the high-resolution electron microscope showed that the obtained sample had a two-dimensional layered structure, and it was a vertically stacked array structure with abu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com