A Deterministic Modification Method for Outer Roundness of Shaft Parts

A deterministic technology for shaft parts, applied in the direction of manufacturing tools, grinding machines, grinding/polishing equipment, etc., can solve the research on the generation mechanism and control methods of abrasive belt grinding and polishing removal functions, and fail to achieve ultra-high precision roundness repair Shape and other problems, to achieve the effect of reducing the performance requirements of the machine tool, good shaping accuracy, and high shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

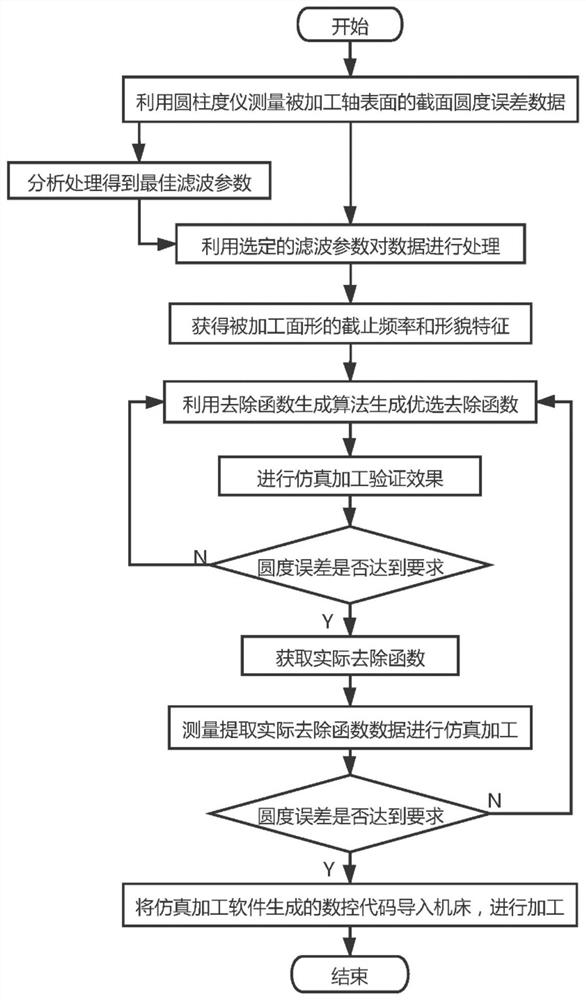

[0046] Such as figure 1 As shown, the method for deterministically modifying the outer roundness of the shaft parts of the present invention, based on the analysis and control of the modification ability, the deterministic modification of the outer roundness includes the following steps:

[0047] 1) The multi-section roundness error data of the surface of the shaft part to be processed is obtained by measuring the cylindricity meter;

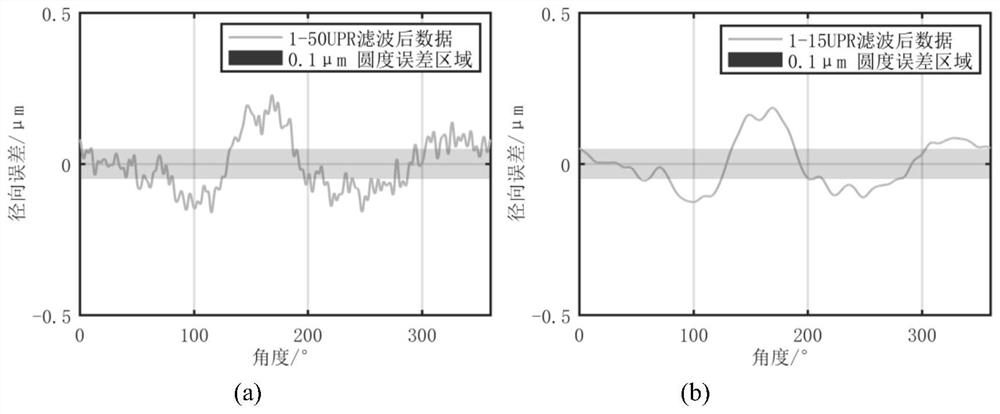

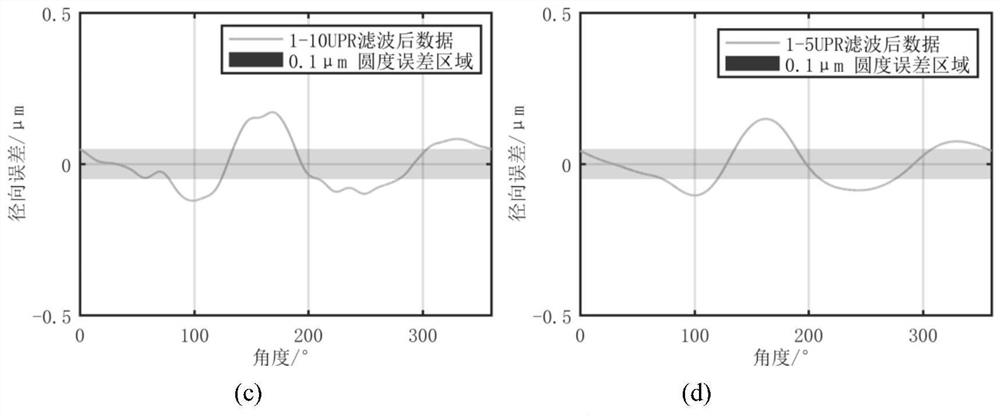

[0048] 2) Perform shape feature extraction and filter characteristic curve drawing on each roundness error data, and obtain the optimal filter parameter range T by simulation in combination with design requirements;

[0049] 3) filtering each roundness error data by using the range T of the filtering parameter;

[0050] 4) Calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com