Polishing device for rice processing

A polishing device, rice processing technology, applied in application, grain finishing, grain processing, etc., can solve problems such as affecting quality and difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

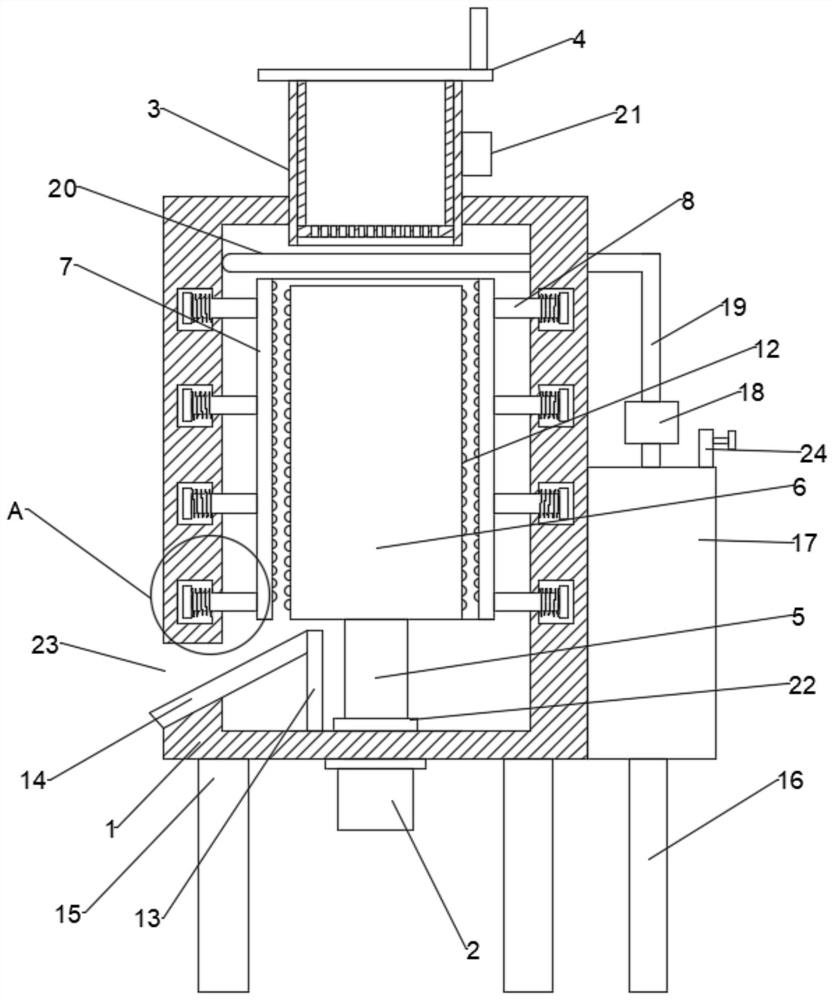

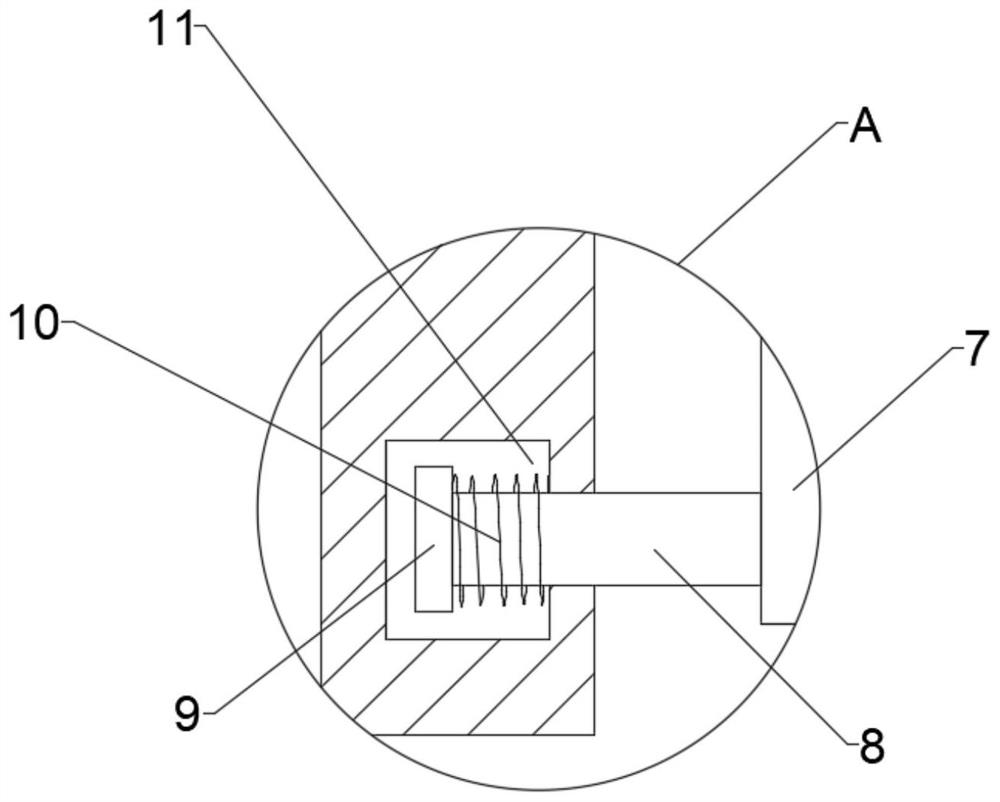

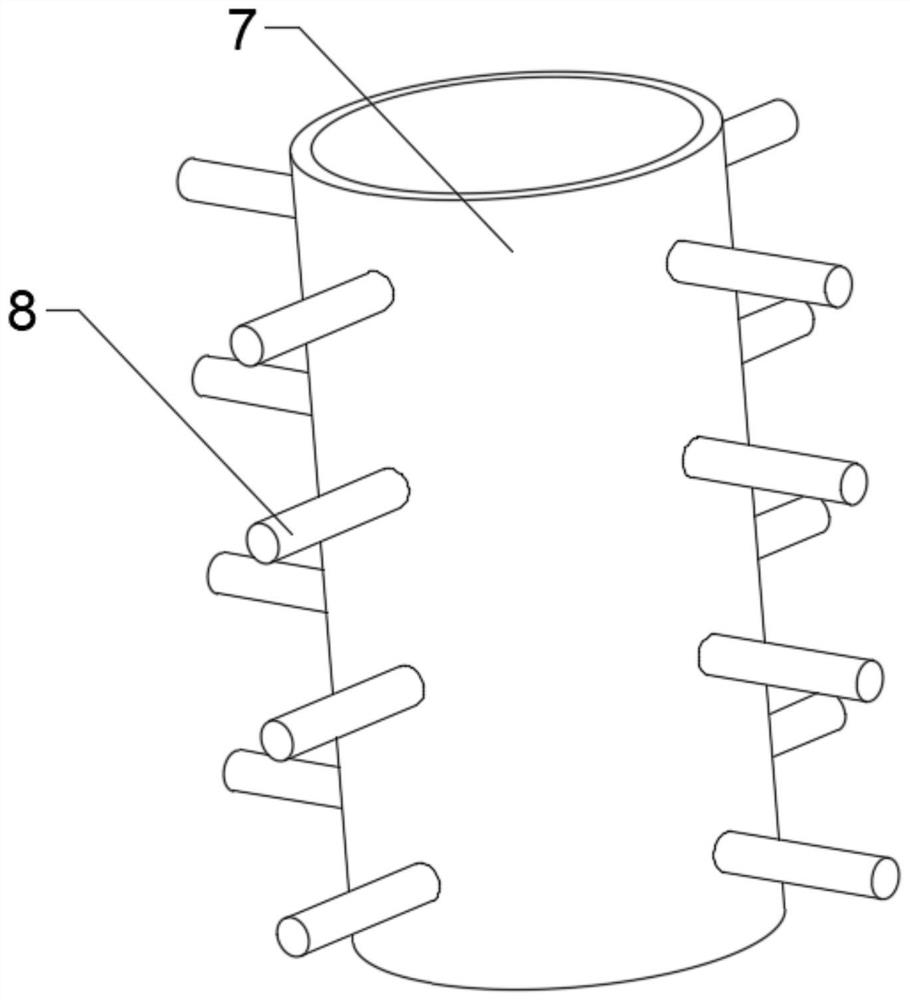

[0025] combine Figure 1-5 , a polishing device for rice processing, comprising a body 1 and a first support column 15, the body 1 is fixed on the upper end of the first support column 15, the upper end of the body 1 is provided with a feed pipe 3 for feeding, The bottom of the feed pipe 3 is provided with a second polishing roller 7, a plurality of connecting rods 8 are fixed on the outside of the second polishing roller 7, and a plurality of convex grooves 11 are provided on the inner wall of the body 1, so that The convex groove 11 is mated with the connecting rod 8, and the connecting rod 8 is fixed with a connecting block 9 near the inner end of the convex groove 11, and a connecting block 9 is fixed between the connecting block 9 and the inner wall of the convex groove 11 The spring 10 sleeved on the outside of the connecting rod 8, the first polishing roller 6 is arranged inside the second polishing roller 7, the lower end of the first polishing roller 6 is fixedly conn...

Embodiment 2

[0032] A polishing device for rice processing, this embodiment further limits the device on the basis of embodiment 1.

[0033] The inside of the feed pipe 3 is plugged with a sieving device 4, the sieving device 4 includes a sieving main body 41, an annular block 42 and a handle 43, and the lower end of the sieving main body 41 is provided with evenly distributed sieving devices. Holes 410, the upper end of the sieve main body 41 is fixed with an annular block 42, the annular block 42 is set for plugging and fixing the sieve main body 41, the annular block 42 is connected with the upper end of the feed pipe 3, the ring block 42 A handle 43 is fixed on the upper end, and the handle 43 is provided to facilitate extraction of the sieve main body 41 , and a vibrating motor 2 is fixed on one side of the feed pipe 3 .

[0034] Specifically, the rice to be polished in the feeding pipe 3 is vibrated and sieved by the vibrating motor 2 to remove the residual rice husk inside, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com