A kind of supported metal oxide catalyst with titanium aluminum carbide as carrier and its preparation method and application

A titanium aluminum carbide and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as NH3 loss, high equipment requirements, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

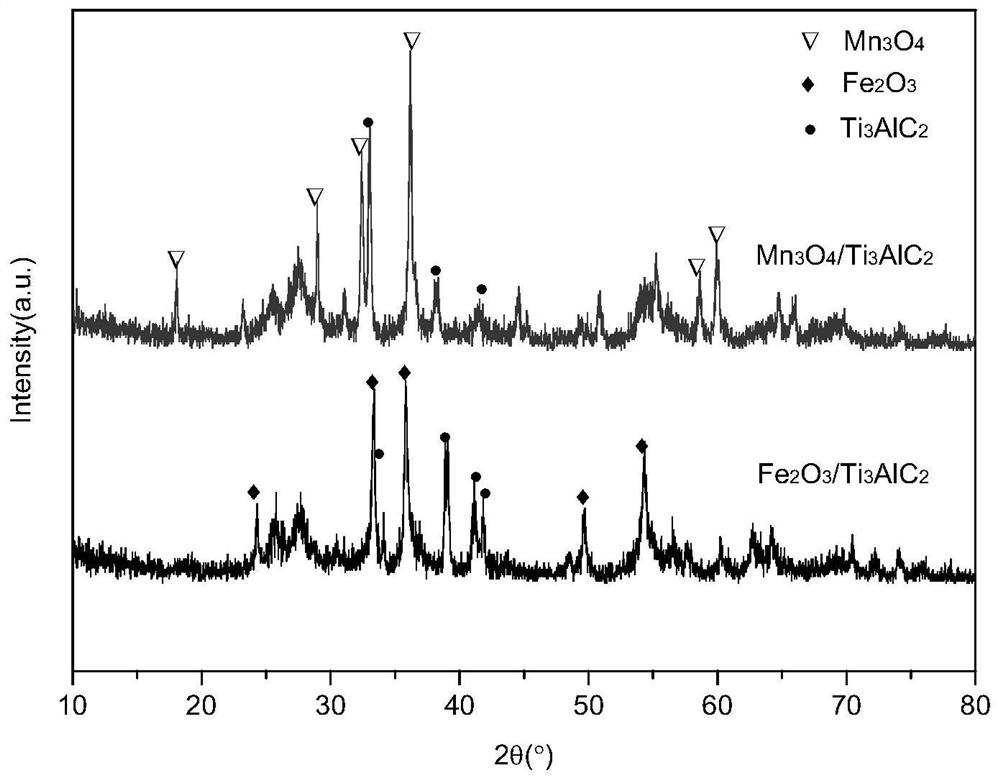

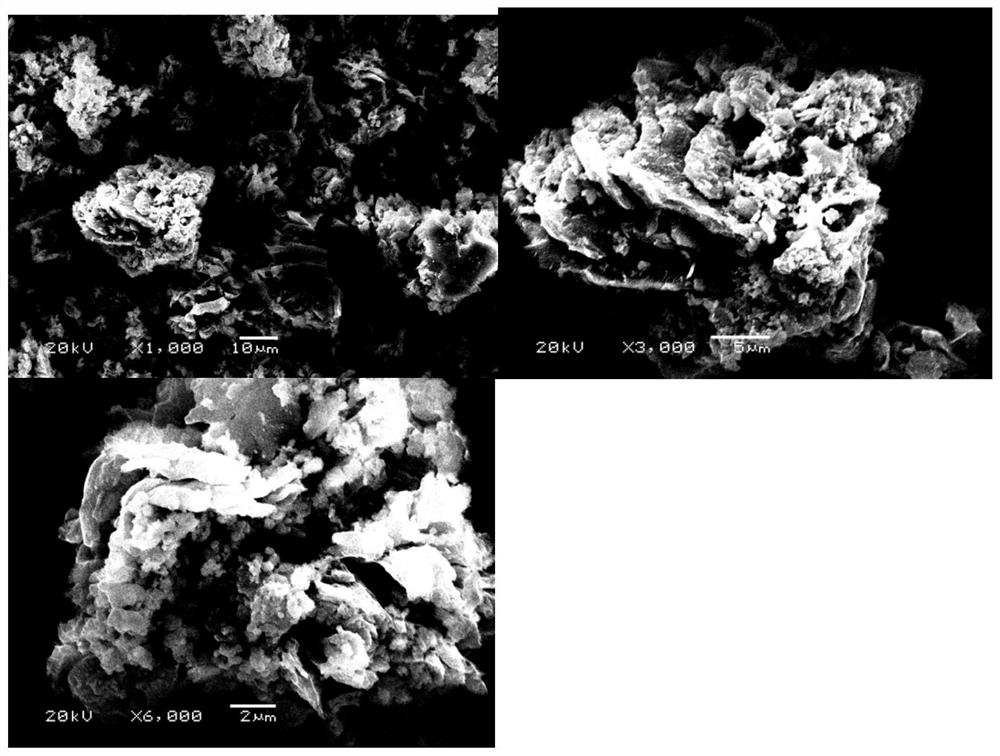

[0046]Weigh 1.946g Ti 3 AlC 2 Mix with 20ml of absolute ethanol, add 4.2028g of citric acid monohydrate, stir in a water bath at 40°C, then add 2ml of ethylene glycol dropwise into the mixture as a dispersant, stir until the mixture is evaporated to dryness to obtain a viscous glue dried in an oven at 150°C for 12 hours to obtain fluffy dry glue, which was ground into powder to obtain porous Ti 3 AlC 2 Precursor carrier. Weigh 2.451g of manganese acetate tetrahydrate and dissolve it in 30ml of deionized water. After it is fully dissolved, add 1.946g of Ti 3 AlC 2 The precursor carrier was fully stirred in a water bath at 60°C until the water was evaporated to dryness, then dried in an oven at 120°C for 10 hours, and finally baked in a muffle furnace at 500°C for 6 hours to obtain Mn 3 o 4 / Ti 3 AlC 2 Denitration catalyst samples

[0047] The obtained samples were tested for denitrification activity, and the catalytic activity test method was as follows: put the cataly...

Embodiment 2

[0049] Weigh 1.946g Ti 3 AlC 2 Mix with 20ml of absolute ethanol, add 4.2028g of citric acid monohydrate, stir in a water bath at 40°C, then add 2ml of ethylene glycol dropwise into the mixture as a dispersant, stir until the mixture is evaporated to dryness to obtain a viscous glue dried in an oven at 150°C for 12 hours to obtain fluffy dry glue, which was ground into powder to obtain porous Ti 3 AlC 2 Precursor carrier. Weigh 3.677g of manganese acetate tetrahydrate and dissolve it in 50ml of deionized water. After it is fully dissolved, add 1.946g of Ti 3 AlC 2 The precursor carrier was fully stirred in a water bath at 60°C until the water was evaporated to dryness, then dried in an oven at 120°C for 10 hours, and finally baked in a muffle furnace at 500°C for 6 hours to obtain Mn 3 o 4 / Ti 3 AlC 2 Denitrification catalyst samples.

[0050] The obtained samples were tested for denitrification activity, and the catalytic activity test method was as follows: put the ...

Embodiment 3

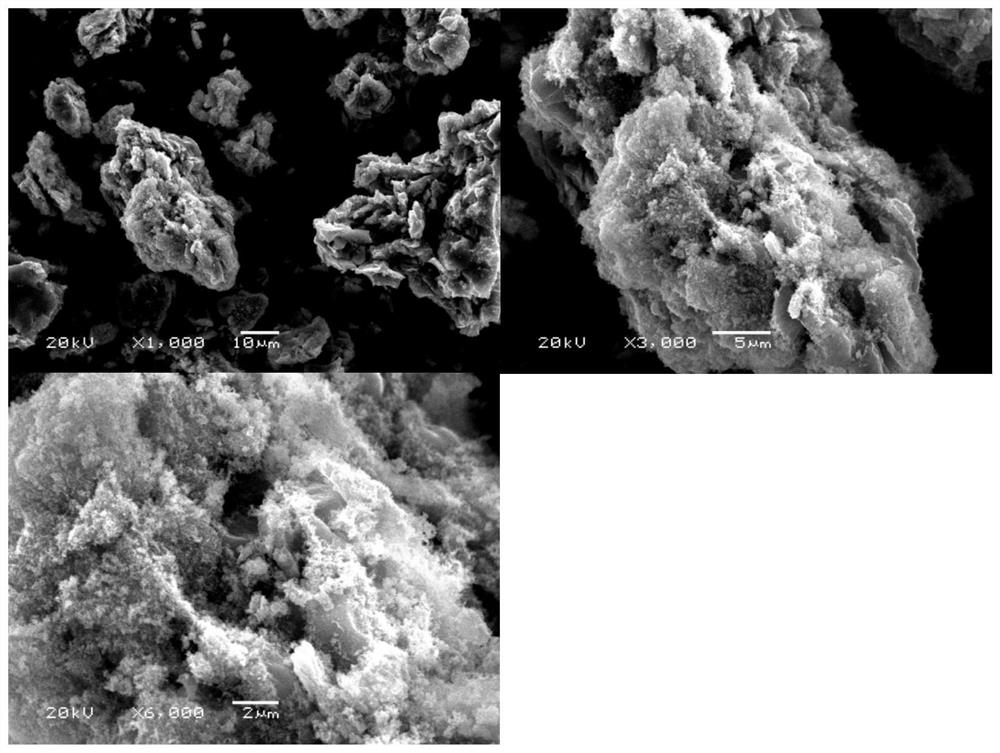

[0052] Weigh 1.946g Ti 3 AlC 2 Mix with 20ml of absolute ethanol, add 4.2028g of citric acid monohydrate, stir in a water bath at 40°C, then add 2ml of ethylene glycol dropwise into the mixture as a dispersant, stir until the mixture is evaporated to dryness to obtain a viscous glue dried in an oven at 150°C for 12 hours to obtain fluffy dry glue, which was ground into powder to obtain porous Ti 3 AlC 2 Precursor carrier. Weigh 4.040 grams of ferric nitrate nonahydrate and dissolve it in 30ml deionized water. After it is fully dissolved, add 1.946g Ti 3 AlC 2 The precursor carrier was fully stirred in a water bath at 60°C until the water evaporated to dryness, then dried in an oven at 120°C for 10 hours, and finally baked in a muffle furnace at 500°C for 6 hours to obtain Fe 2 o 3 / Ti 3 AlC 2 Denitrification catalyst samples.

[0053] The obtained sample was tested for denitrification activity. The catalytic activity test method is: put the catalyst in a fixed bed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com