A method of producing agarwood powder and essential oil by using white wood aroma mist bacon

A kind of agarwood incense powder and white wood incense technology, applied in the field of agarwood, can solve the problems of affecting the enthusiasm of practitioners, low resource utilization, slow investment return, etc., to improve resource supply, improve utilization, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

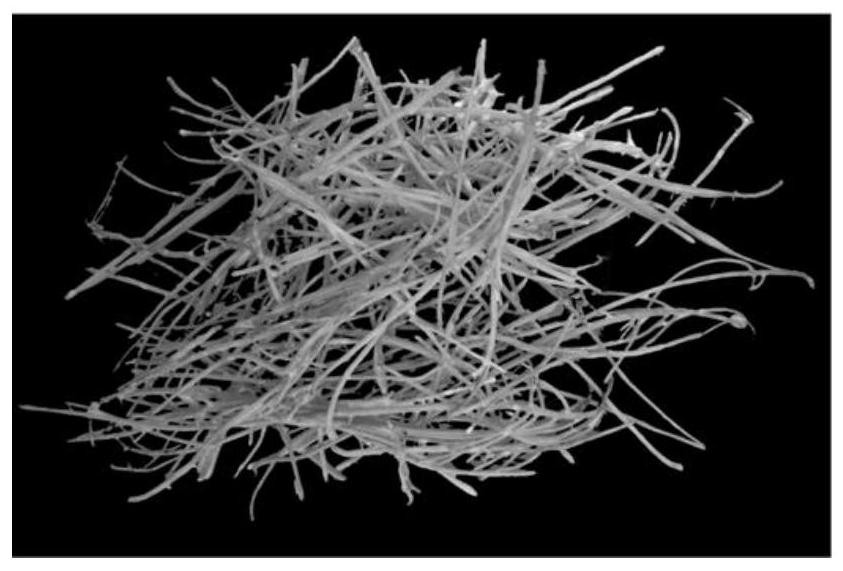

[0046] (1) Seedling bag nursery

[0047] Utilize the conventional technology that those skilled in the art can understand to carry out the seedling cultivation of A. sinensis seeds, but need to increase specific measures to obtain the specific plant type suitable for transplanting aerosol culture, namely root system, plant height, branch, crown width, blade The principle goal is that the main root is upright and easy to distribute evenly in the aerosol environment. The plant height is suitable for plant fixation, cultivation equipment load-bearing and covering and moisturizing operations. There are branches, a large number of leaves, and a large crown to ensure the protection of the aboveground part. Photosynthetic center strength.

[0048] The specific measures different from the conventional seedling cultivation procedures of A. sinensis seeds are: (A) inserting a round paper tube in the middle of the seedling bag to limit the early germination of the seeds to ensure that th...

Embodiment 2

[0060] The difference from Example 1 is that the selected plant type is 1.5 years old, and the method of agarwood inducer (polymer functional membrane liquid) is different, as follows.

[0061] Disperse 1.9 g of carrier β-cyclodextrin (β-CD) in 50 mL of deionized water at 60°C to obtain a β-cyclodextrin carrier solution, add 1 mL of agarwood to the β-cyclodextrin carrier solution to induce Factor methyl jasmonate, at room temperature, stir in a homogenizer at high speed for 1 hour, add 1.2 g of base film sodium methylcellulose (CMC) to 1 mL of absolute ethanol to disperse, add 80 mL of deionized water while stirring, and make the base Membrane methylcellulose sodium is completely dissolved, then add 0.3g of organic acid naphthaleneacetic acid, 0.5g of glucose, 1.2g of inorganic salt potassium chloride, and set the volume to 100mL, at 500r / min, the β-cyclodextrin / Methyl jasmonate solution is mixed with sodium methylcellulose solution in a volume ratio of 1:2. Add an equal vol...

Embodiment 3

[0063] The difference from Example 1 is that the selected plant type is 2.5 years old, and the method of agarwood inducer (polymer functional membrane liquid) is different, as follows.

[0064] Disperse 2.1 g of carrier β-cyclodextrin (β-CD) in 50 mL of deionized water at 60°C to obtain a β-cyclodextrin carrier solution. Add 7 mL of β-cyclodextrin carrier solution to the concentration of 40% agarwood inducing factor ethephon aqueous solution, in a water bath at 60°C for 30min; add 0.3g organic acid indole butyric acid, 1.0g sucrose and 1.2g inorganic salt sodium chloride to 20mL deionized water while stirring; then, in At 500r / min, mix with β-cyclodextrin / ethephon solution, and add 180mL of 10% basement membrane soluble chitosan solution, bathe in water at 60°C for 30 minutes and fully stir, then stand at 60°C for 30 minutes , to remove the air bubbles on its surface, and at the same time make the various substances in the solution fully cross-linked and blended.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com