Waste heat recovery device for coating environment-friendly mechanical equipment

A technology of waste heat recovery equipment and mechanical equipment, applied in heat exchange equipment, lighting and heating equipment, heat exchangers, etc., can solve the problems of less waste heat recovery, less heat conduction pipes, and short residence time of hot air heat conduction pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

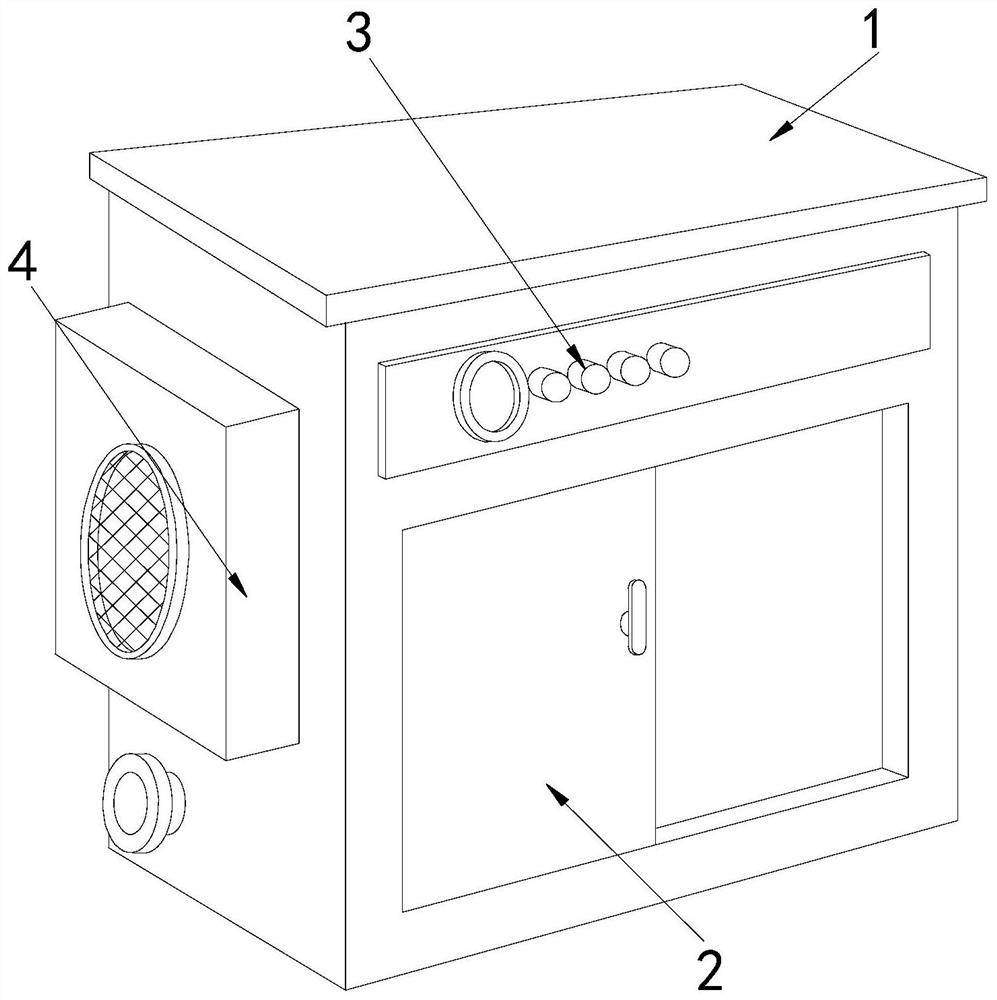

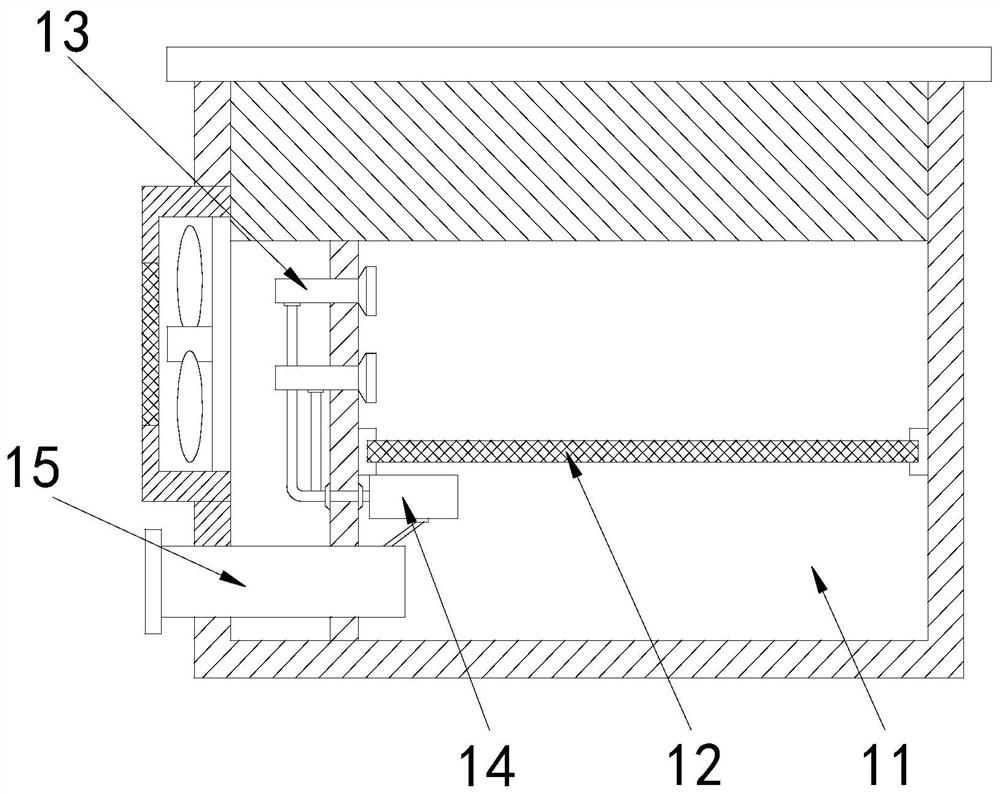

[0027] Its structure includes a main body 1, a box door 2, a control button 3, and a fan 4. The front end of the main body 1 is provided with a box door 2. The control button 3 is located at the upper end of the box door 2. At the side end, the main body 1 includes a drying box 11, a carrier plate 12, an air inlet 13, a circulation pipe 14, and a ventilation valve 15. The carrier plate 12 is installed horizontally inside the drying box 11, and the air inlet 13 Set at the side end of the drying box 11, the circulation pipe 14 is set at the lower end of the air inlet 13 and connected to the bottom of the air inlet 13, the ventilation valve 15 is installed at the bottom of the drying box 11, and runs through in subject 1.

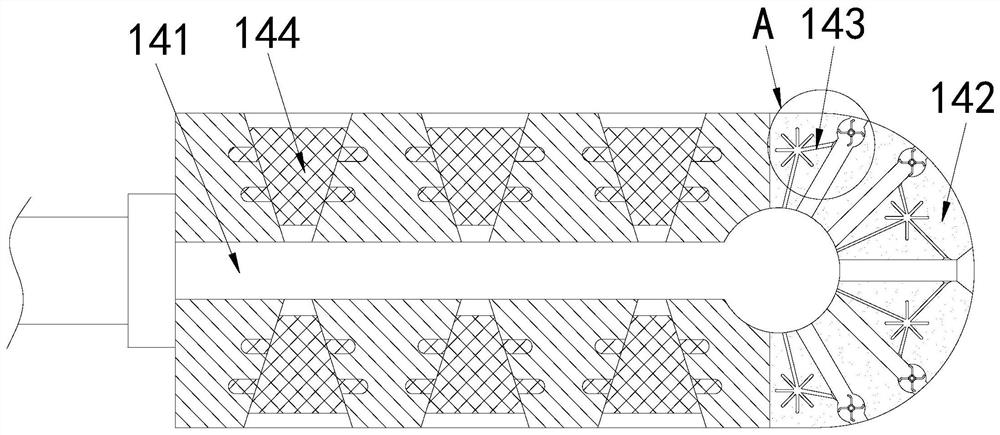

[0028] The circulation pipe 14 includes a ventilation groove 141, a heat conduction head 142, a heat conduction device 143, and a heat ...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The heat-absorbing block 144 includes a heat-absorbing hole b1, an air guide block b2, and a heat-absorbing groove b3. There are more than five heat-absorbing holes b1, which are scattered from the bottom to the top. The air guide block b2 is provided with ten More than one, and attached to the side end of the heat-absorbing hole b1, the air-guiding block b2 is provided with four, and installed in pairs on the side end of the heat-absorbing block 144, the air-guiding block b2 is triangular in shape, It is beneficial to allow the airflow to flow back and forth in the heat absorption hole b1 and increase the contact time of the airflow with the heat absorption block 144 .

[0034] The heat-absorbing groove b3 includes a return groove b31, a perforation b32, a windshield block b33, and a diversion hole b34. One group is respectively arranged at the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com