High-frequency response porous PEDOT: PSS thin-film material and preparation method and application thereof

A high-frequency response and thin-film material technology, applied in the field of filter capacitors, can solve the problems of hindering the exposure of PEDOT active sites and large internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the high-frequency response porous PEDOT:PSS film material is as follows:

[0033] Step 1. Take 50 μL of PEDOT:PSS aqueous solution in a 1.5 mL centrifuge tube, add 13 vol% polar co-solvent DMSO, and mix evenly by ultrasonic to obtain a mixed solution;

[0034] Step 2. Use a pipette gun to take 9 μL of the mixed solution obtained in Step 1, spin coat it on filter paper, and place it in an oven at 80°C to dry for 10 minutes;

[0035] Step 3, treating the above sample with concentrated sulfuric acid at room temperature for 12-24 h;

[0036] Step 4: Clean it with deionized water, place it in an oven at 80 °C and dry it for 2-3 minutes to obtain a high-frequency response porous PEDOT:PSS film material with an area of 0.5×0.5 cm 2 .

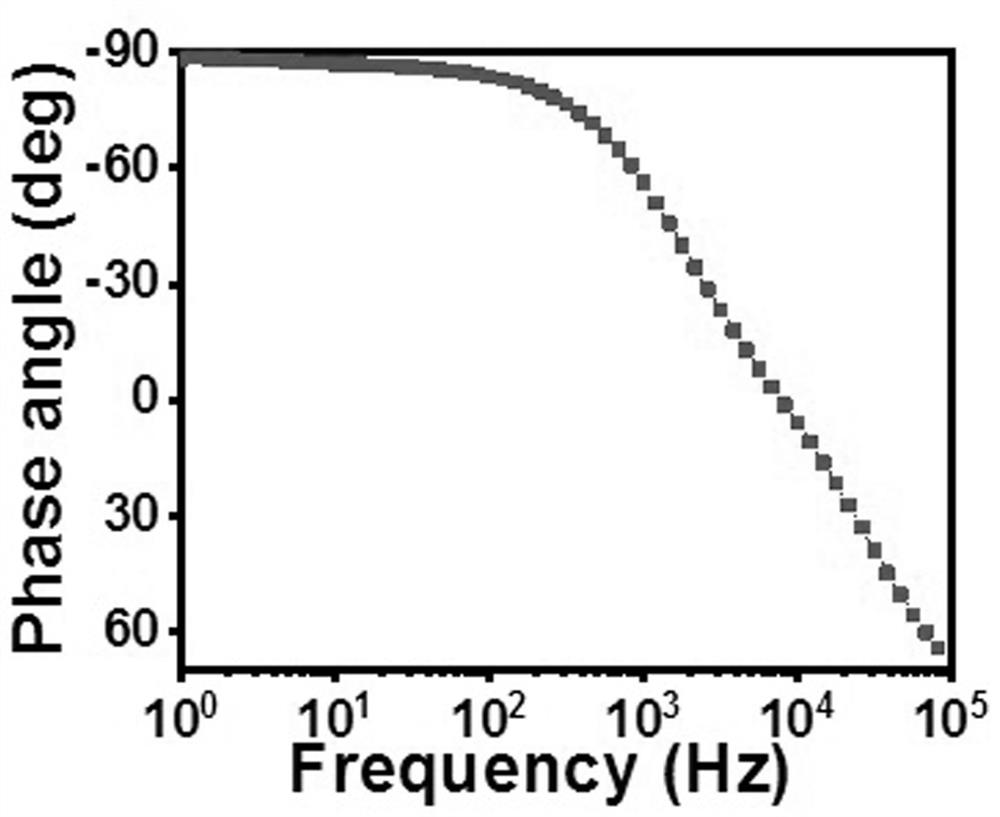

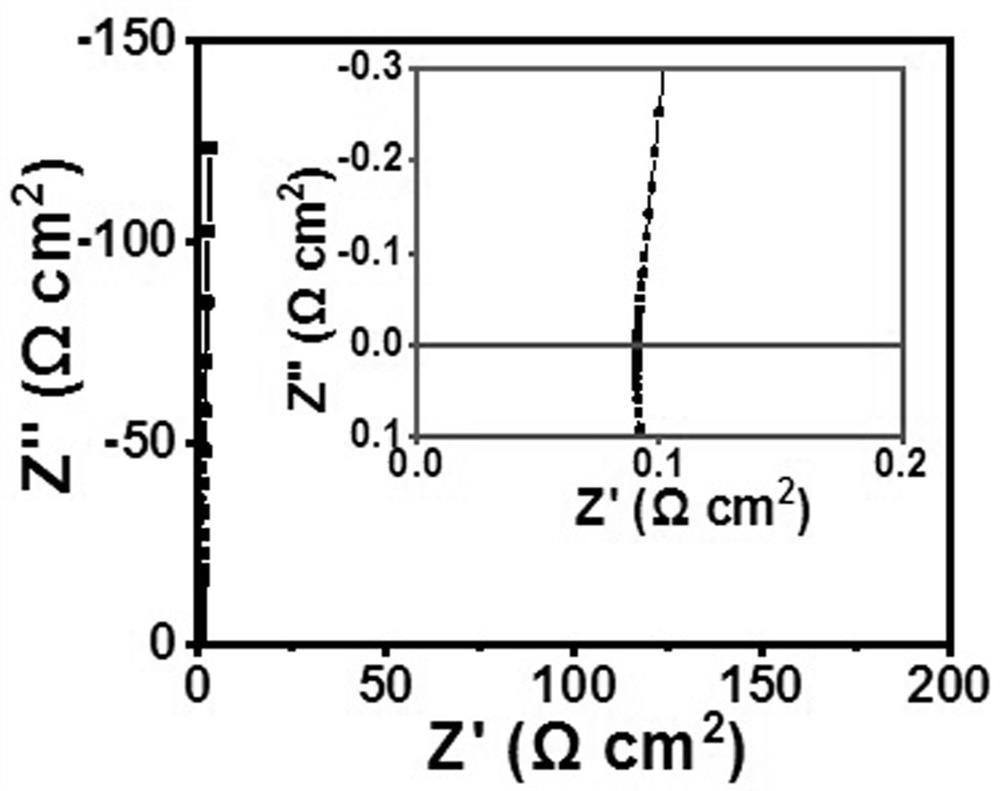

[0037] Performance Testing

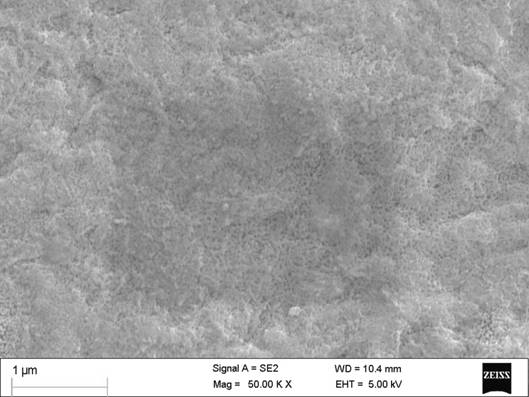

[0038] ①Scanning electron microscope characterization

[0039] The high-frequency response porous PEDOT:PSS thin film material that embodiment 1 makes is carried out morphology charac...

Embodiment 2

[0045] Others are the same as in Example 1, except that the volume percentage of the co-solvent DMSO added is 0 vol%.

Embodiment 3

[0047] Others are the same as in Example 1, except that the volume percentage of the added co-solvent DMSO is 5 vol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com