Preparation method of high-molecular ultraviolet light absorber

A technology of polymerization and ultraviolet light, applied in the direction of coating, etc., can solve the problems of cumbersome process operation, low grafting rate, and content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of polymerized ultraviolet light absorber, the method comprises the following steps:

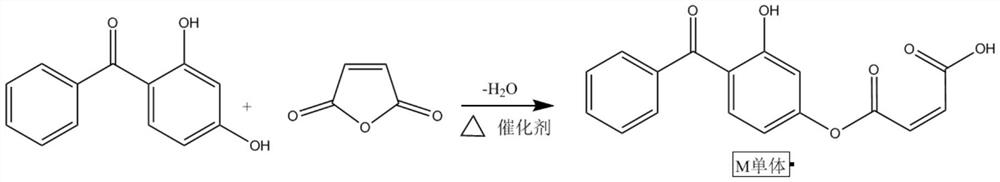

[0029] (1) 214g (1.0mol) of the small molecule ultraviolet absorber UV-0 (2,4-dihydroxybenzophenone) is placed in a glass flask, 5g of p-toluenesulfonic acid is added, 250g of ethyl acetate is added, and stirred Make it dissolve completely and add 98g (1.0mol) of maleic anhydride while stirring, heat to 80°C, react under stirring, check the pH to 6-8 (test by dropping the reaction solution onto a pH test paper wetted with water), It can be judged that the reaction is complete, the temperature is lowered and cooled, that is, the reaction solution of polymerized monomer M with ultraviolet light absorption function is formed;

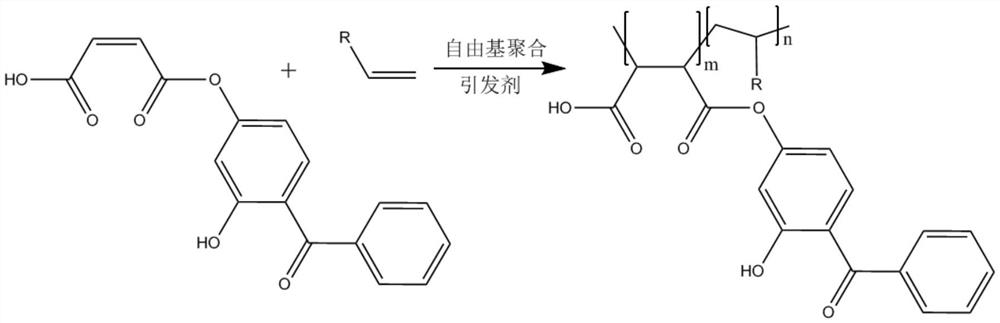

[0030] (2) Add 104g (1.0mol) of styrene monomer to the above reaction system, add 15g of AIBN (azobisisobutyronitrile), stir to dissolve it, slowly raise the temperature to 80°C, and react for 6h under continuous stirring. Form a polymerized ...

Embodiment 2

[0032] A preparation method of polymerized ultraviolet light absorber, the method comprises the following steps:

[0033] (1) 214g (1.0mol) of the small molecule ultraviolet absorber UV-0 (2,4-dihydroxybenzophenone) is placed in a glass flask, 5g of p-toluenesulfonic acid is added, 250g of ethyl acetate is added, and stirred Make it dissolve completely and add 98g (1.0mol) maleic anhydride while stirring, heat to 110°C, react under stirring, check the pH to 6-8 (test by dropping the reaction liquid onto a pH test paper wetted with water), It can be judged that the reaction is complete, the temperature is lowered and cooled, that is, the reaction solution of polymerized monomer M with ultraviolet light absorption function is formed;

[0034] (2) Add 43g (0.5mol) of acrylic acid monomer and 50g (0.5mol) of methyl methacrylate to the above reaction system, add 15g of BPO (benzoyl peroxide), stir to dissolve, and slowly heat up to 110°C , reacting for 4 hours under continuous sti...

Embodiment 3

[0037] A preparation method of polymerized ultraviolet light absorber, the method comprises the following steps:

[0038] (1) 214g (1.0mol) of the small molecule ultraviolet absorber UV-0 (2,4-dihydroxybenzophenone) is placed in a glass flask, 5g of p-toluenesulfonic acid is added, 250g of ethyl acetate is added, and stirred Make it dissolve completely and add 98g (1.0mol) maleic anhydride while stirring, heat to 100°C, and under stirring, check the pH to 6-8 (test by dropping the reaction solution onto a pH test paper wetted with water), that is It can be judged that the reaction is complete, the temperature is lowered and cooled, and vacuum-dried, that is, the polymerized monomer M with ultraviolet light absorption function is formed;

[0039] (2) Add 500g of water to the mixture of 104g (1.0mol) of polymerized monomer M, 56.8g (0.8mol) of acrylamide and 200g (0.2mol) of allyl polyethylene glycol (molecular weight 1000), and add 20g of AIBA (azobisisobutylamidine hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com