Preparation method of pentaerythritol ester

A technology for pentaerythritol ester and pentaerythritol is applied in the field of preparation of pentaerythritol ester, and can solve the problems of many by-products, difficult recycling of catalysts, and difficulty in achieving industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

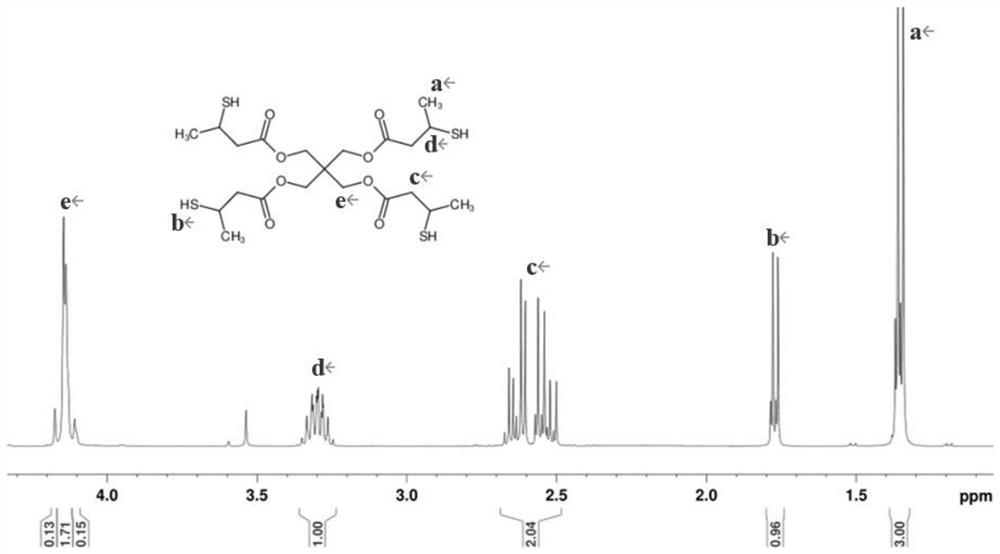

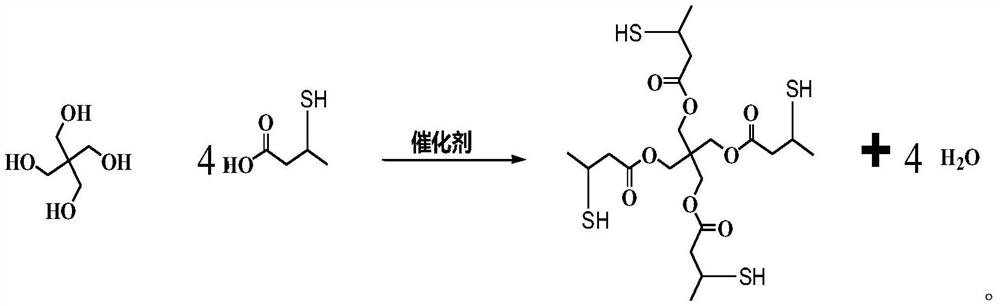

Image

Examples

Embodiment 1

[0056] 1. Catalyst H 3 PW 12 o 40 -Methanesulfonic acid / Mesoporous TiO 2 Preparation of:

[0057] A) 30.5 g of template agent P12 and 5 g of isopropyl titanate were stirred in ethanol for 1 h and mixed evenly to obtain the first mixed solution;

[0058] B) the first mixed solution and heteropolyacid H 3 PW 12 o 40 1 g, 1 g of methanesulfonic acid were stirred for 1 h and mixed uniformly to obtain the second mixed solution;

[0059] C) volatilize the second mixed solution at 40° C. for 12 hours to remove the solvent to obtain a gel;

[0060]D) Aging at 100°C for 12h, and then calcining at 350°C for 2h to remove the template agent and obtain catalyst H 3 PW 12 o 40 -Methanesulfonic acid / Mesoporous TiO 2 . The particle size of the catalyst is 3nm and the specific surface area is 200m 2 / g.

[0061] 2, the preparation of pentaerythritol ester

[0062] (1) In the four-neck flask equipped with mechanical stirring, thermometer, reflux condenser and water trap, add 41.2...

Embodiment 2

[0072] 1. Catalyst H 3 SiW 12 o 40 -Sulphamic acid / mesoporous TiO 2 Preparation of:

[0073] A) 31 g of template agent P12 and 8 g of n-butyl titanate were stirred in methanol for 0.5 h and mixed uniformly to obtain the first mixed solution;

[0074] B) the first mixed solution and heteropolyacid H 3 SiW 12 o 40 3g, 1g of sulfamic acid were stirred for 1h and mixed uniformly to obtain the second mixed solution;

[0075] C) volatilize the second mixed solution at 40° C. for 13 hours to remove the solvent to obtain a gel;

[0076] D) Aging at 100°C for 14h, and then calcining at 400°C for 2h to remove the template agent to obtain catalyst H 3 SiW 12 o 40 -Sulphamic acid / mesoporous TiO 2 . The particle size of the catalyst is 3.5nm and the specific surface area is 180m 2 / g.

[0077] 2, the preparation of pentaerythritol ester

[0078] (1) In the four-necked flask that mechanical stirring, thermometer, reflux condenser and water separator are housed, add 41.27g of ...

Embodiment 3

[0086] 1. Catalyst H 3 PW 12 o 40 -Methanesulfonic acid / mesoporous SiO 2 Preparation of:

[0087] A) 30.8 g of template agent P12 and 7 g of ethyl orthosilicate were stirred in acetonitrile for 1.5 h and mixed uniformly to obtain the first mixed solution;

[0088] B) the first mixed solution and heteropolyacid H 3 PW 12 o 40 2g and 2g of methanesulfonic acid were stirred for 1h and mixed uniformly to obtain the second mixed solution;

[0089] C) volatilize the second mixed solution at 40° C. for 10 h to remove the solvent to obtain a gel;

[0090] D) aging at 100°C for 12h, and then calcining at 400°C for 1.5h to remove the template agent and obtain catalyst H 3 PW 12 o 40 -Methanesulfonic acid / mesoporous SiO 2 . The particle size of the catalyst is 4nm and the specific surface area is 210m 2 / g.

[0091] 2, the preparation of pentaerythritol ester

[0092] (1) In the four-neck flask equipped with mechanical stirring, thermometer, reflux condenser and water sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com