Narrow gap welding process method for ultra-thick plates

A welding process, narrow gap technology, used in welding equipment, welding accessories, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

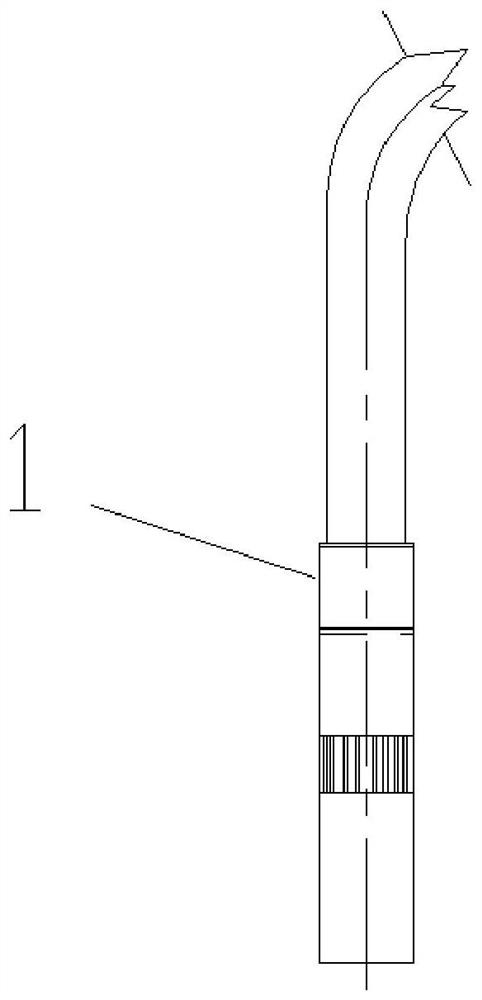

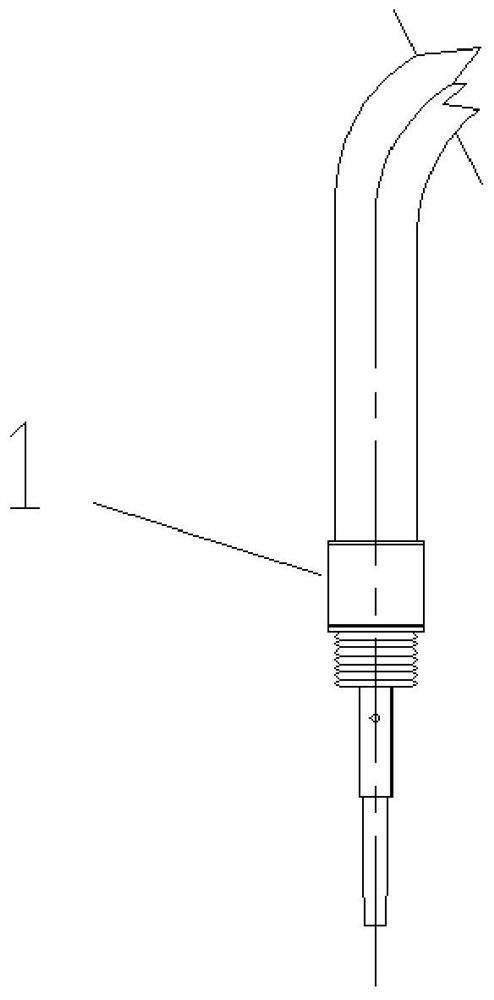

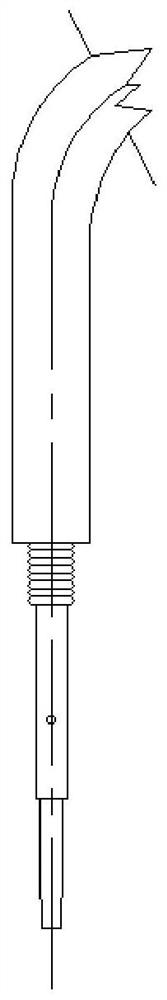

Image

Examples

Embodiment Construction

[0029] The invention relates to a narrow-gap welding process for ultra-thick plates.

[0030] 1. First, use flame, mechanical and other cutting methods to process the groove of the thick plate, cut into an I-shaped groove surface, check whether there are groove marks on the groove surface, and repair the groove surface if it exceeds 1mm. The groove surface is polished and smooth; CO2 gas shielded welding is used for surfacing welding at the center of both sides of the groove surface. Before surfacing welding, the thick plate needs to be preheated at 150-250°, and the welding meat of 4-8mm is surfacing , and the welding meat is polished and processed to form a raised welding strip with a cross-section approximately triangular, forming a double U-shaped groove surface without blunt edges ( Figure 7 ); Grind the groove surface after processing, and carry out PT inspection on the groove surface, and assemble after confirming that there is no defect.

[0031] 2. The two groove fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com