Garbage deodorant and preparation method thereof

A technology for deodorant and garbage, which is applied in the field of chemical deodorant and its preparation, and can solve problems such as the psychological and physiological impact of staff and operators who deal with garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

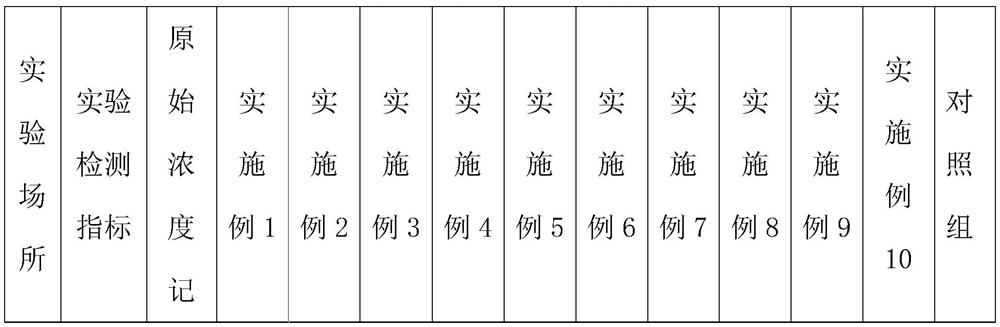

Embodiment 1

[0038] According to the corresponding proportion, 10 grams of hydrogenated castor oil, 1 gram of oleylamine polyoxyethylene ether, 6 grams of lauryl methacrylate and 30 grams of polysorbate-80 were mixed for 1 minute to obtain standby A;

[0039] Mix 3 grams of dimethylolbutyric acid, 2 grams of chloramine-T, 1 gram of aluminum chloride, 1 gram of cyclodextrin and 100 grams of water for 2 minutes to obtain standby B;

[0040] Mix Standby A and Standby B to get the finished product.

Embodiment 2

[0042] According to the corresponding proportion, 10 grams of hydrogenated castor oil, 1 gram of oleylamine polyoxyethylene ether, 6 grams of lauryl methacrylate and 30 grams of polysorbate-80 were mixed for 20 minutes to obtain standby A;

[0043] Mix 3 grams of dimethylolbutyric acid, 2 grams of chloramine-T, 1 gram of aluminum chloride, 1 gram of cyclodextrin and 100 grams of water for 30 minutes to obtain standby B;

[0044] Mix Standby A and Standby B to get the finished product.

Embodiment 3

[0046] According to the corresponding proportion, 80 grams of hydrogenated castor oil, 15 grams of oleylamine polyoxyethylene ether, 30 grams of lauryl methacrylate and 150 grams of polysorbate-80 were mixed for 1 minute to obtain standby A;

[0047] Mix 15 grams of dimethylolbutyric acid, 20 grams of chloramine-T, 6 grams of aluminum chloride, 6 grams of cyclodextrin and 600 grams of water for 2 minutes to obtain standby B;

[0048] Mix Standby A and Standby B to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com