Ti3C2/MnCo2S4 composite hybrid electrode material and preparation method thereof

A technology of electrode materials and hybrid materials, applied in chemical instruments and methods, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as limited applications, expensive compounds, and low electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

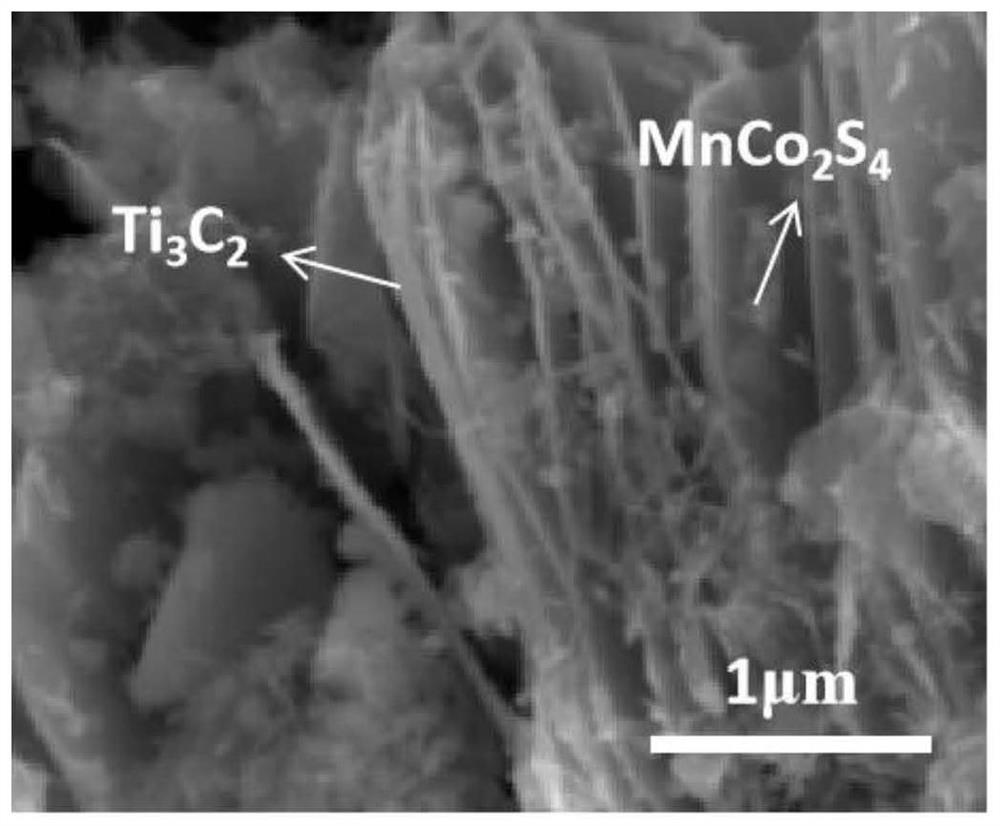

[0040] The embodiment of the present invention is environmentally friendly, simple preparation process, good charge and discharge cycle stability and rate performance, high specific capacitance and high energy density Ti 3 C 2 / MnCo 2 S 4 Composite hybrid electrode material and preparation method, specifically including:

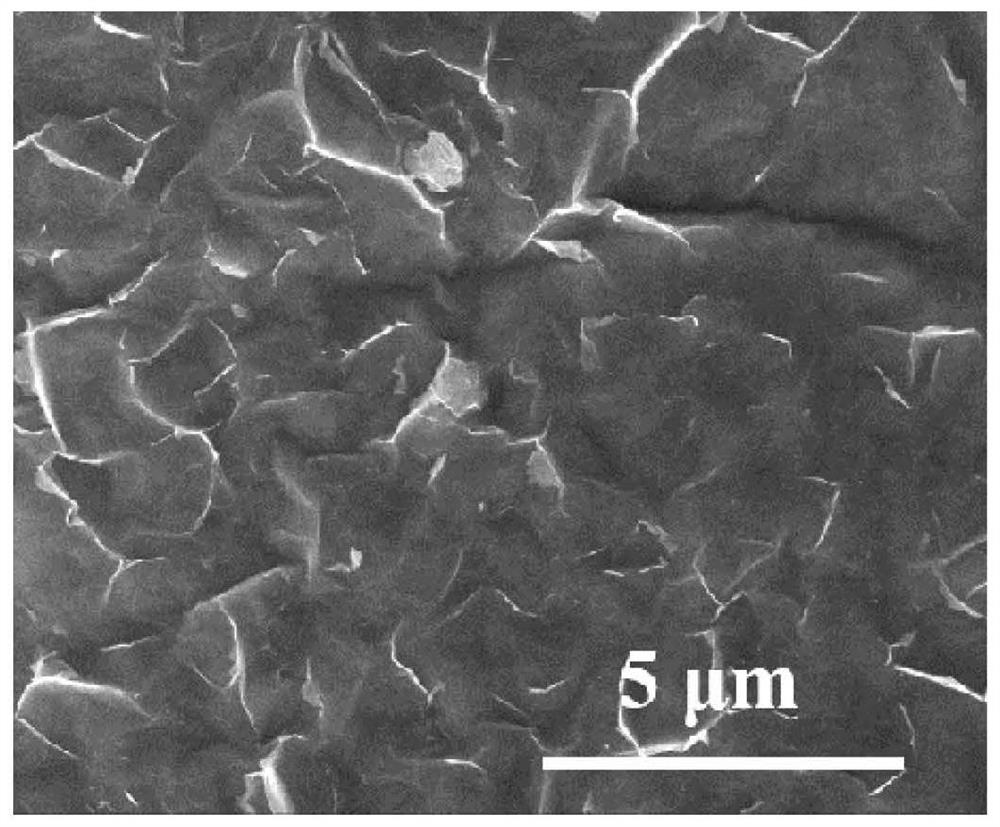

[0041] (1) Accordion-shaped Ti 3 C 2 Preparation of: Etching Ti with a mixture of LiF and HCl 3 AlC 2 method to prepare Ti 3 C 2 , specifically: Measure 2-15ml of concentrated hydrochloric acid and 1-10ml of deionized water, slowly add the concentrated hydrochloric acid into a polytetrafluoroethylene container filled with deionized water; weigh 0.1-5g of LiF powder and add it to the above-mentioned diluted In hydrochloric acid, after LiF is completely dissolved, add 0.1-3g MAX phase ceramic powder Ti 3 AlC 2 Add slowly. Put the container on a magnetic stirrer, adjust the temperature to 20-50°C, and adjust the speed to 100-300r / min. After reacting ...

Embodiment 1

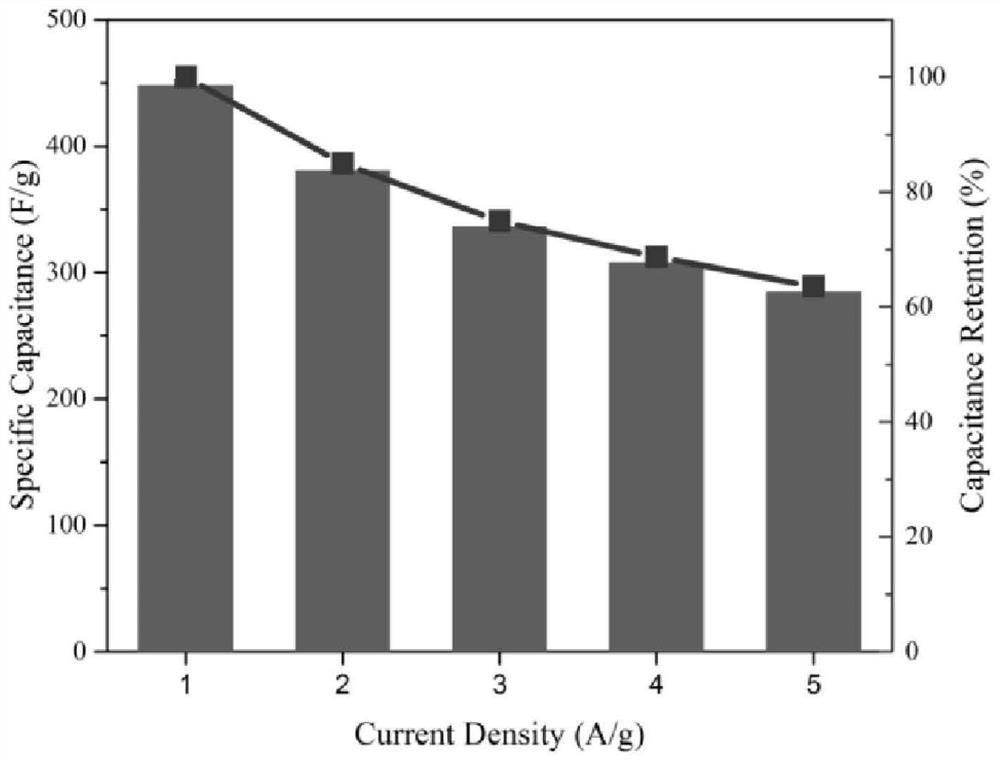

[0057] Example 1: Ti 3 C 2 / MnCo 2 S 4 Preparation of Composite Hybrid Electrode Materials and Testing of Electrochemical Properties

[0058] Step 1: Accordion Ti 3 C 2 Preparation of: Etching Ti with a mixture of LiF and HCl 3 AlC 2 method to prepare Ti 3 C 2 , specifically: Measure 2-15ml of concentrated hydrochloric acid and 1-10ml of deionized water, slowly add the concentrated hydrochloric acid into a polytetrafluoroethylene container filled with deionized water; weigh 0.1-5g of LiF powder and add it to the above-mentioned diluted In hydrochloric acid, after LiF is completely dissolved, add 0.1-3g MAX phase ceramic powder Ti 3 AlC 2 Add slowly. Put the container on a magnetic stirrer, adjust the temperature to 20-50°C, and adjust the speed to 100-300r / min. After reacting for 10-30 hours, collect and wash the product to obtain dark green Ti 3 C 2 solution.

[0059] Step 2: Single-layer or few-layer Ti 3 C 2 Preparation of materials: The accordion-shaped Ti ...

Embodiment 2

[0066] Example 2: Ti 3 C 2 / MnCo 2 S 4 Preparation of Composite Hybrid Electrode Materials and Testing of Electrochemical Properties

[0067] Step 1: Accordion Ti 3 C 2 Preparation of: Etching Ti with a mixture of LiF and HCl 3 AlC 2 method to prepare Ti 3 C 2, specifically: Measure 2-15ml of concentrated hydrochloric acid and 1-10ml of deionized water, slowly add the concentrated hydrochloric acid into a polytetrafluoroethylene container filled with deionized water; weigh 0.1-5g of LiF powder and add it to the above-mentioned diluted In hydrochloric acid, after LiF is completely dissolved, add 0.1-3g MAX phase ceramic powder Ti 3 AlC 2 Add slowly. Put the container on a magnetic stirrer, adjust the temperature to 20-50°C, and adjust the speed to 100-300r / min. After reacting for 10-30 hours, collect and wash the product to obtain dark green Ti 3 C 2 solution.

[0068] Step 2: Single-layer or few-layer Ti 3 C 2 Preparation of materials: The accordion-shaped Ti p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com