Steel tube triangle truss supporting system and construction method

A technology of triangular truss and support system, which is applied in the direction of house structure support, house structure support, scaffolding for house structure support, etc., can solve the problems of increasing cost and increasing difficulty of formwork installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

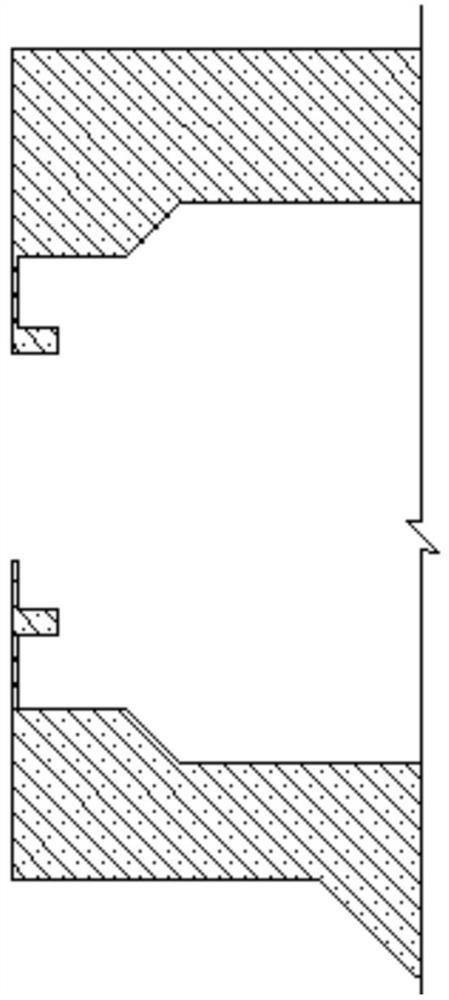

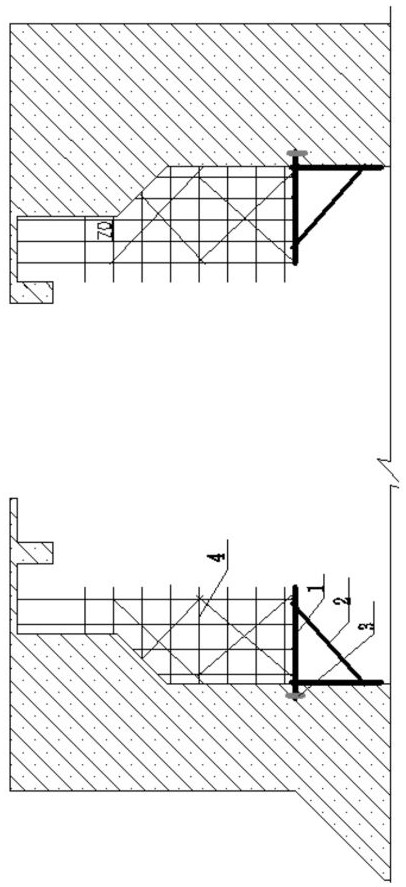

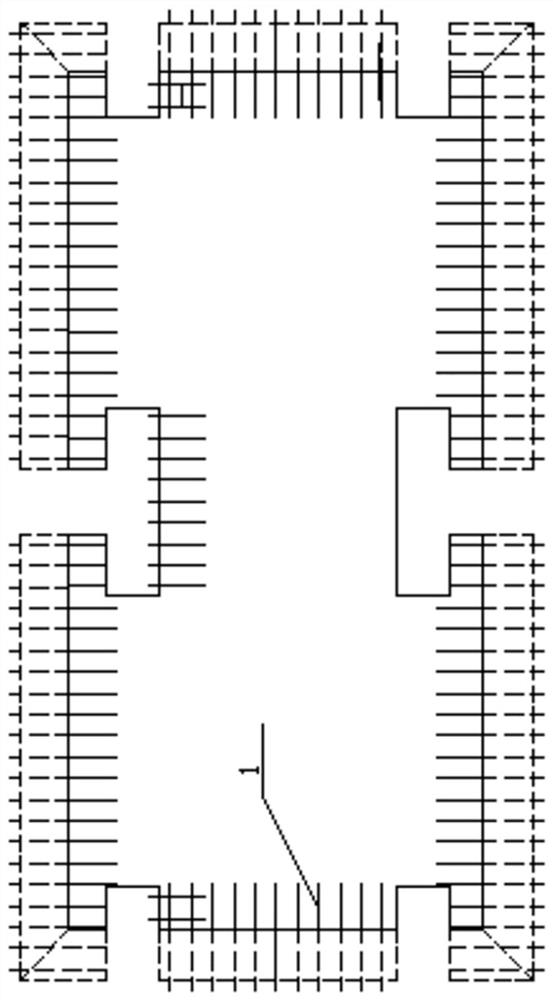

[0034] Such as Figure 1-Figure 4 As shown, taking the 1# diversion tunnel of Shuangjiangkou Hydropower Station as an example to illustrate, the entrance is equipped with a double-hole lock chamber with length×width=15×19m (the overall stake number of the lock chamber is 0+000~0-025), and the top elevation is EL2308, lock chambers above EL2286 are mainly concrete frame structures, the inside of the upper wall of the lock chamber between EL2303. 8 pillars of 1.7m.

[0035] When the upper wall of the lock chamber is poured to the EL2303.6 elevation, the cantilever chamfer (or corbel) is poured along the inner side of the wall. The cantilever length is 1.4m, and the overall cantilever length is 68m. The ratio is 1:1, and the total height is 4.4m.

[0036] Since the bottom of the cantilever is 19m away from the top plate of the gate hole f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com