Self-air-entraining ternary hydraulic jump stilling basin

A technology of stilling pool and stilling pool floor, which is applied in the directions of hydropower generation, hydropower station, water conservancy project, etc., can solve the problems of increasing project investment, cavitation damage of stilling pool floor and side wall, and endangering structural safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

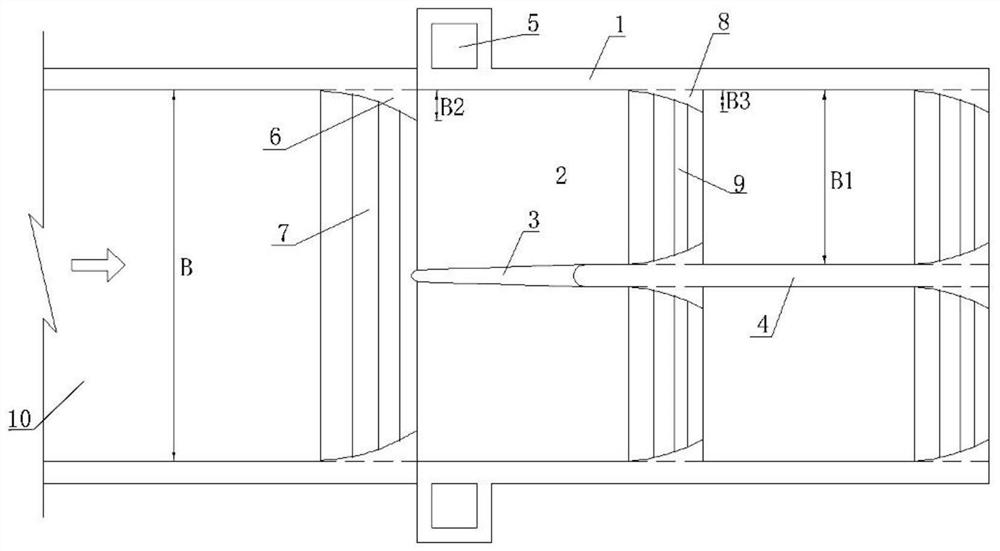

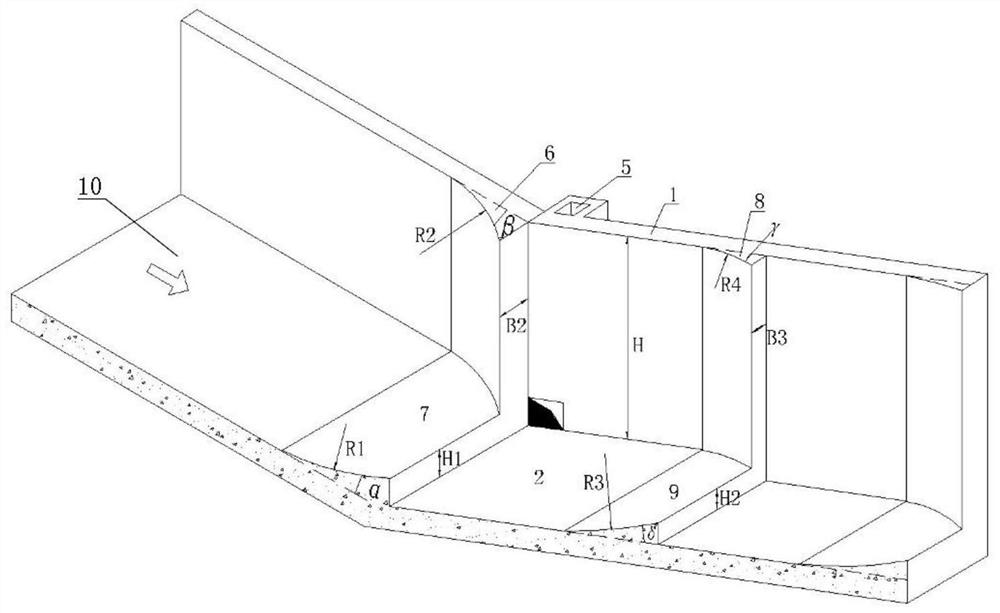

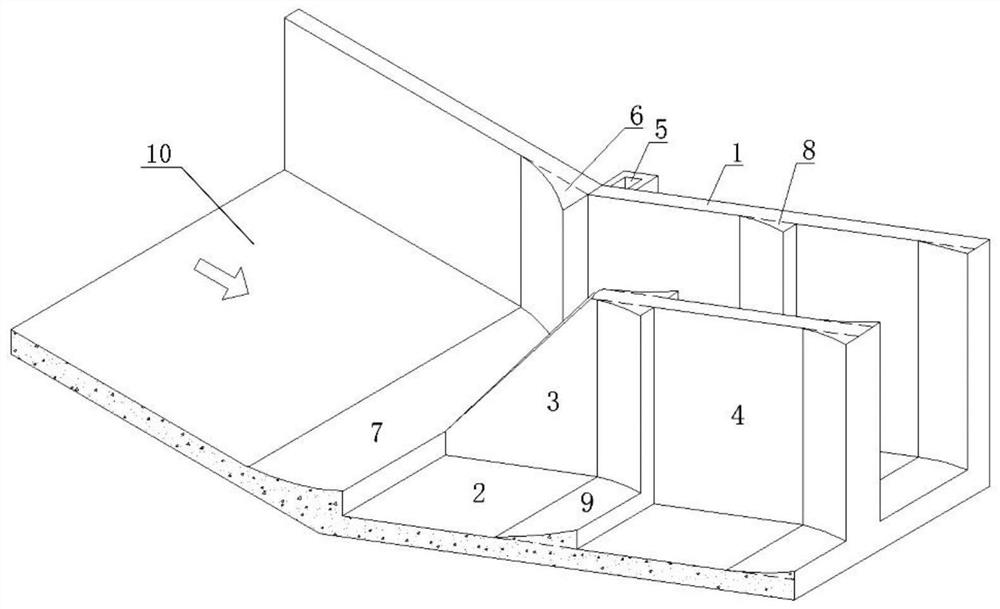

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes the following components: stilling pool side wall 1, stilling pool bottom plate 2, diversion pier 3, middle partition wall 4, ventilation shaft 5, anti-arc paste angle 6, anti-arc drop sill 7, lateral paste Angle 8, stilling ridge 9, chute 10.

[0027] The specific implementation is as follows:

[0028] The side wall 1 of the stilling pool and the bottom plate 2 of the stilling pool are respectively connected with the side wall and bottom plate of the upstream chute 10, and the middle part of the stilling pool is provided with a diversion pier 3 and a middle partition wall 4, and the middle partition wall 4 is connected to the side wall 1 of the stilling pool The width of B1 is B1, and the width of B1 is determined according to the actual situation. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com