A seawater desalination system for recovering various waste heat of diesel engines

A diesel engine and waste heat technology, which is used in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve the problem that the waste heat of flue gas has not been developed and utilized, and achieves the goal of avoiding internal scaling, avoiding dew point acidification, and ensuring stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings. The following is only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

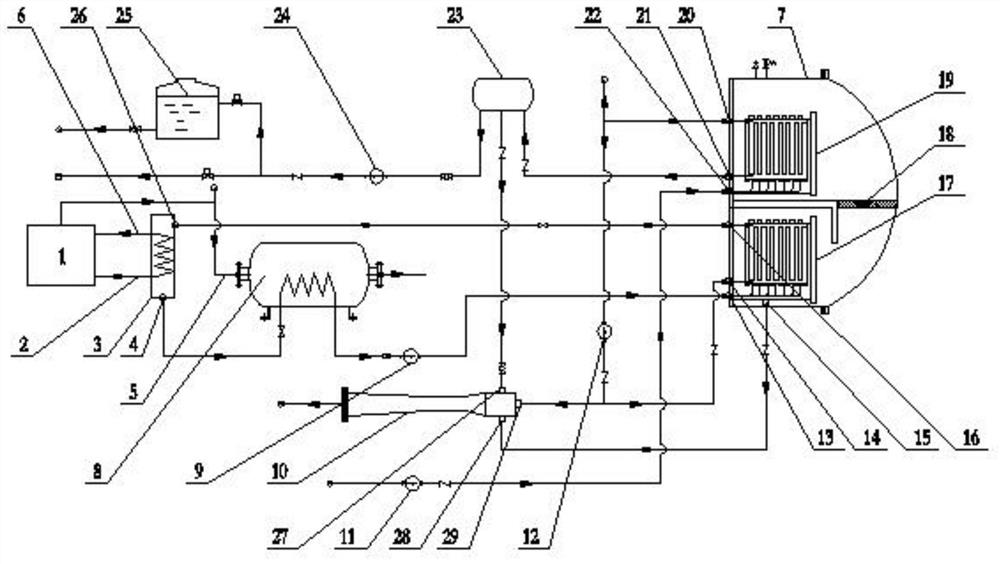

[0013] A seawater desalination system for recovering various waste heat of diesel engines (see figure 1 ), including diesel engine 1, first heat exchanger 3, second heat exchanger 8, water jet vacuum pump 10, evaporator 17, condenser 19, product water buffer tank 23, product water tank 25, the evaporator 17 and The condenser 19 is arranged in the casing 7, the condenser is arranged above the evaporator, and a foam trapping device 18 is arranged between the evaporator and the condenser; The other end is connected to the first heat exchanger 3, one end of the cylinder liner water inlet pipe 6 is connected to the first heat exchanger 3, and the other end is connected to the cylinder liner water tank of the diesel engine; the heat transfer medium ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com