A kind of magnetic sheet toy and preparation method thereof

A magnetic sheet and toy technology, applied in the field of plastic products, can solve the problems of poor air circulation, adverse physical and mental health of children, and decreased air quality, and achieve the effects of good water absorption, improved antibacterial washability, and prevention of infection with bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

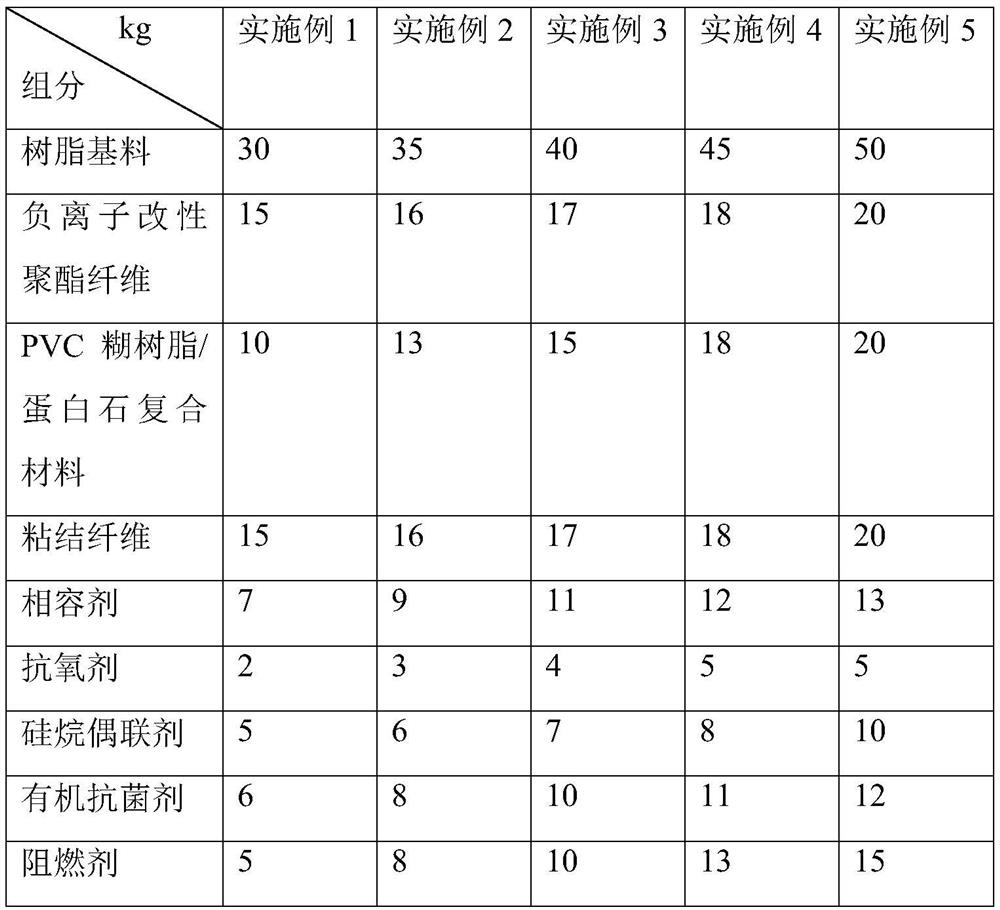

Examples

preparation example 1-3

[0042] In the preparation example 1-3, the PVC paste resin is selected from the PVC paste resin whose article number is P450 sold by Rongbei (Shanghai) Chemical Technology Co., Ltd., and the kelp powder is selected from the kelp powder whose article number is 094 sold by Jiangsu Jinjie Food Co., Ltd., seaweed The powder is selected from the seaweed powder sold by Shenzhen Hengsheng Biotechnology Co., Ltd. with item number 002.

preparation example 1

[0043] Preparation example 1: (1) Dry the loofah and opal at 70°C for 2 hours, pulverize, add the opal powder into the triethanolamine solution, stir for 1 hour, take it out, dry it at 80°C, put the loofah powder in three In the methylpropanethiol solution, heat at 180°C for 2h, the mass ratio of loofah powder, opal powder and trimethylpropanethiol solution is 1:0.8:1.2, and the mass ratio of opal powder and triethanolamine solution is 1 :1;

[0044] (2) Mix PVC paste resin with kelp powder and seaweed powder evenly, heat up to 160°C, stir for 2 hours, then cool down to 100°C, add opal powder and loofah powder while stirring, continue stirring for 20 minutes, vacuumize and degas, Cool to room temperature, the preparation of PVC paste resin, seaweed part and seaweed powder is 1:0.5:0.3, the mass ratio of PVC paste resin, opal powder and loofah powder is 1:1.2:2, the particle size of seaweed powder and seaweed powder 200nm.

preparation example 2

[0045] Preparation Example 2: (1) Dry the loofah and opal at 75°C for 1.5h, pulverize, add the opal powder into the triethanolamine solution, stir for 1.5h, take it out, dry it at 85°C, put the loofah powder in In trimethylpropanethiol solution, heated at 190°C for 1.8h, the mass ratio of loofah powder, opal powder and trimethylpropanethiol solution is 1:0.9:1.3, the mass of opal powder and triethanolamine solution The ratio is 1:1.2;

[0046] (2) Mix PVC paste resin with kelp powder and seaweed powder evenly, heat up to 170°C, stir for 1.5 hours, then cool down to 150°C, add opal powder and loofah powder while stirring, continue stirring for 40 minutes, vacuumize and degas , cooled to room temperature, the preparation of PVC paste resin, seaweed part and seaweed powder is 1:0.7:0.4, the mass ratio of PVC paste resin, opal powder and loofah powder is 1:1.3:2.5, the grain size of seaweed powder and seaweed powder The diameter is 200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com