Lens for slowing down myopia deepening and preparation method thereof

A lens and myopia technology, applied to lenses, glasses/goggles, and other household appliances, can solve problems such as uneven film layers and affecting transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

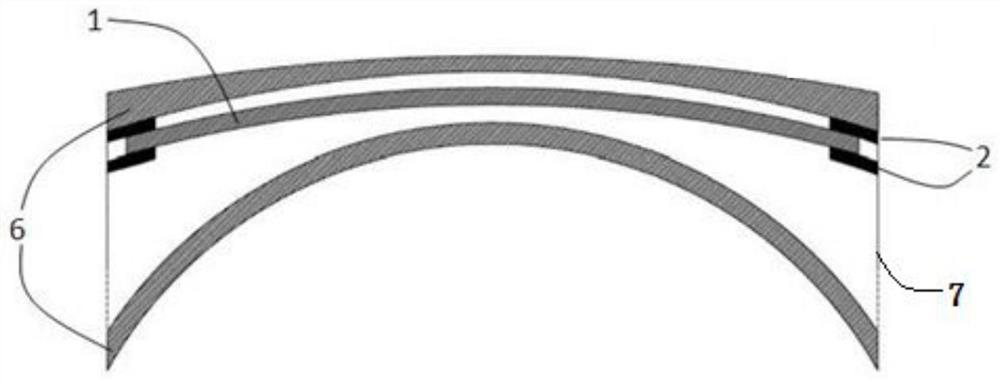

[0038] The preparation method of the above lens specifically comprises the following steps:

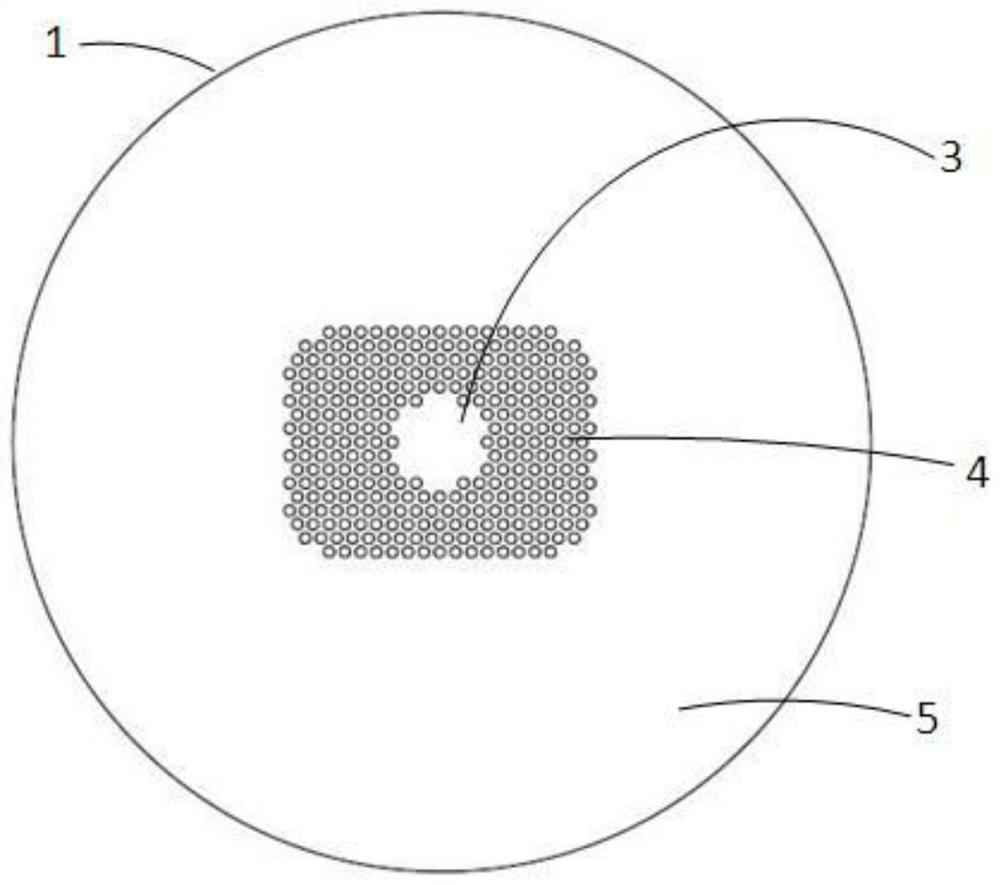

[0039] The first step is to prepare the optical plastic film 1 and prepare the microlens 401 on the surface of the optical plastic film 1 . Among them, the optical plastic film 1 is a hard plastic film, and its material can be PC (polycarbonate), PA (nylon), TAC (triacetyl cellulose), PVA (polyvinyl alcohol), CAB (cellulose acetate butyrate), etc. ), PET (polycarbonate), PMMA (polymethyl methacrylate), PS (polystyrene) and other optical materials.

[0040] Since the size of the microlens 401 produced on the optical plastic film 1 is in the order of millimeters and the depth is in the order of microns, there are several ways to operate such a fine structure, such as thermocompression molding, solvent etching molding, or laser engraving molding.

[0041] The specific method for preparing the microlens 401 on the optical plastic film 1 by thermocompression molding technology is as follo...

Embodiment 1

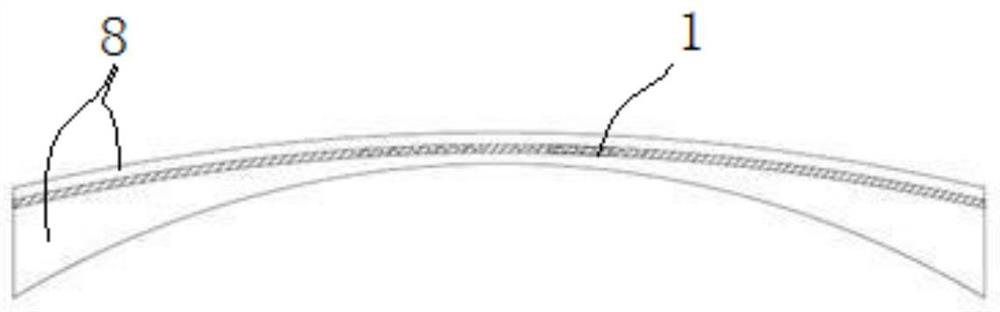

[0051] A TAC film material with a thickness of 0.20 mm is selected as the optical plastic film 1, and a 1.67 polyurethane material is selected as the lens resin monomer to produce a myopia prevention and control lens that can produce a defocusing effect. The TAC optical plastic film 1 can be processed by thermal embossing or laser precise cutting to process the out-of-focus refraction area 4, and this embodiment selects the method of thermal embossing. The refractive index of the TAC material is 1.475, and the refractive index of the polyurethane resin lens material is 1.67. Select the optimal addition luminosity of +3.50D, and derive the formula R= It can be calculated that the radius of curvature R of the microlens 401 is 55.7 mm. Since the refractive index of the TAC material is smaller than that of the resin monomer, the microlens 401 of the out-of-focus refraction area 4 on the optical plastic film 1 is processed with a concave surface, and the hot-molded template is des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com