Electric primer emission controller based on CAN bus

A launch controller and CAN bus technology, applied in the field of electric primer launch controller, can solve problems such as abnormal resistance value of electric primer, lack of remote operation of electric primer, wrong transmission of electric primer, etc., to solve the problem of uncertain pin level safety, avoid accidental launch, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

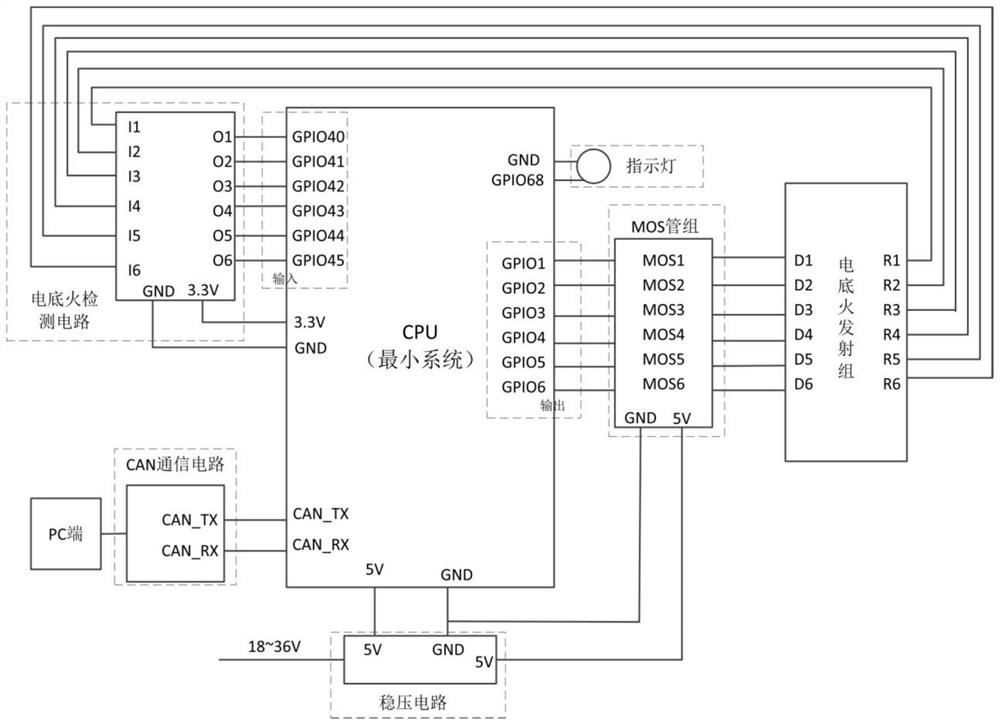

[0020] A kind of electric primer emission controller based on CAN bus of the present invention comprises CAN bus circuit, MOS tube circuit, voltage stabilizing circuit, electric primer resistance detection circuit, protection circuit, indicator light, circuit control system; Said circuit control system Including crystal oscillator circuit, download circuit, power supply circuit, reset circuit, switch circuit, CPU;

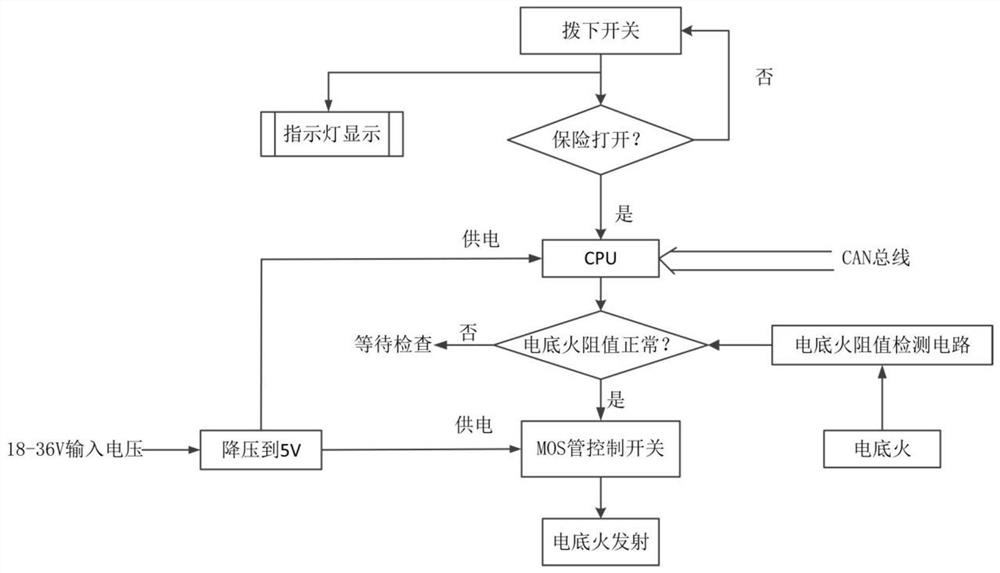

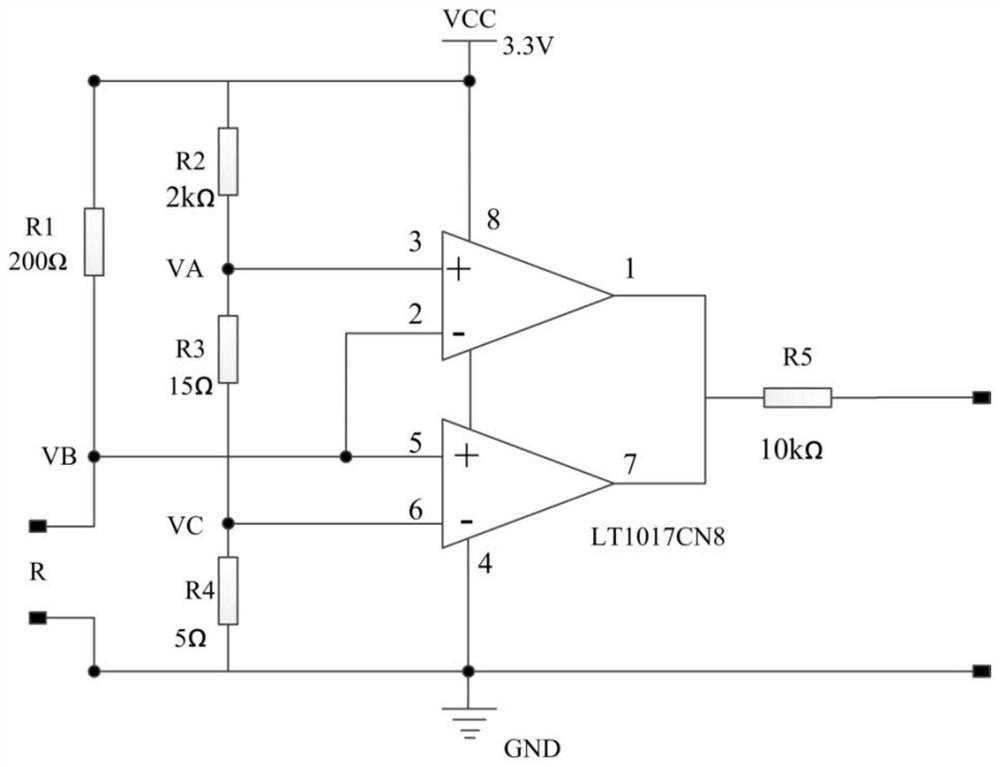

[0021] The protection circuit is connected with the MOS tube circuit and the electric primer resistance detection circuit, and is used to isolate the MOS tube circuit, the electric primer resistance detection circuit from the minimum circuit control system, and prevents the pin level uncertainty at the moment of power-on from causing danger; the voltage stabilizing circuit is connected to a 18-36V power supply to stabilize the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com