Motor vehicle engine waste gas treatment system integrated with silencing structure

A technology of exhaust gas treatment and engine, applied in the direction of machines/engines, engine components, mufflers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

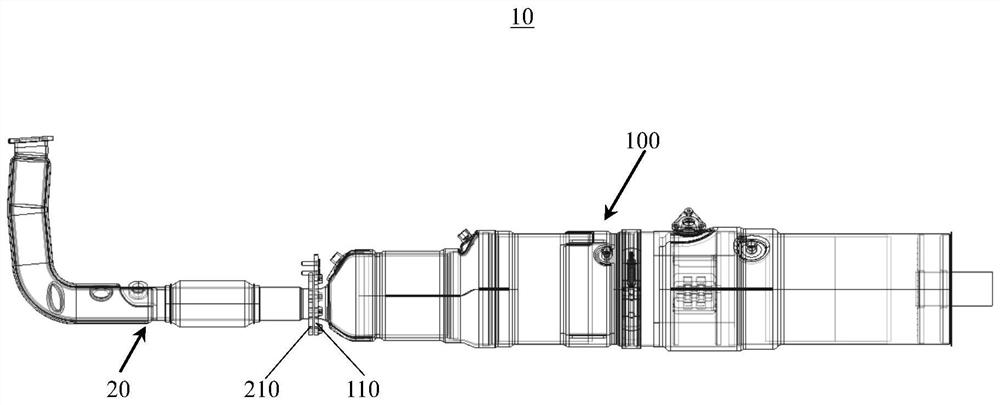

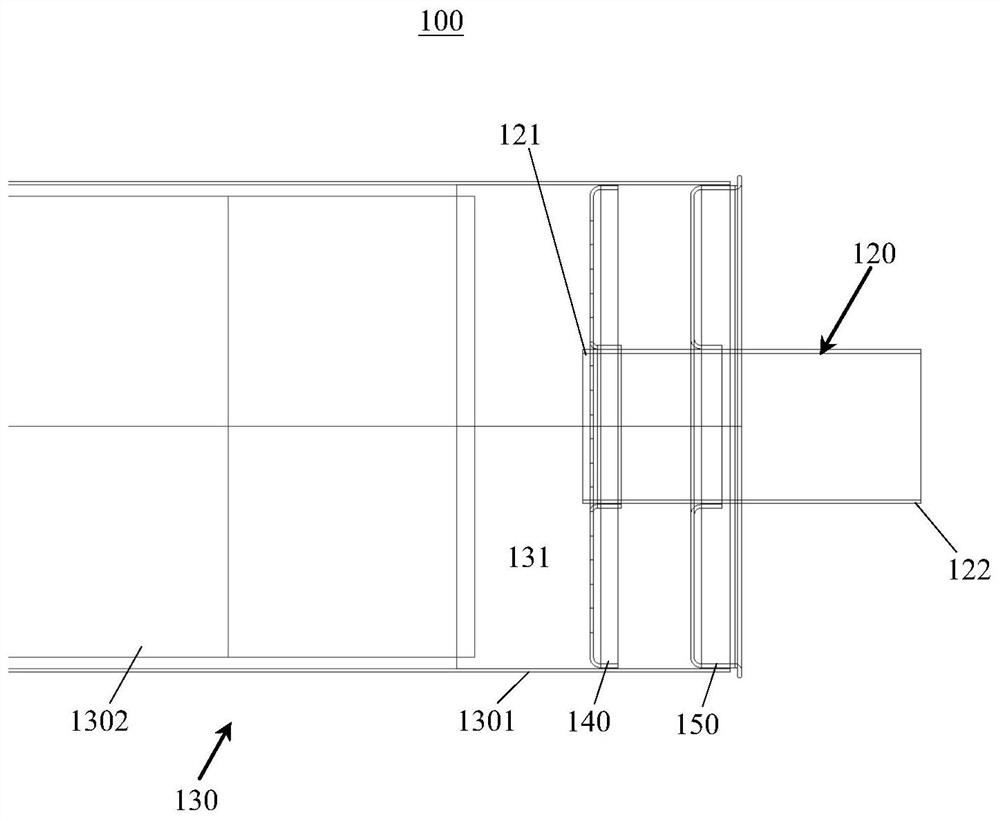

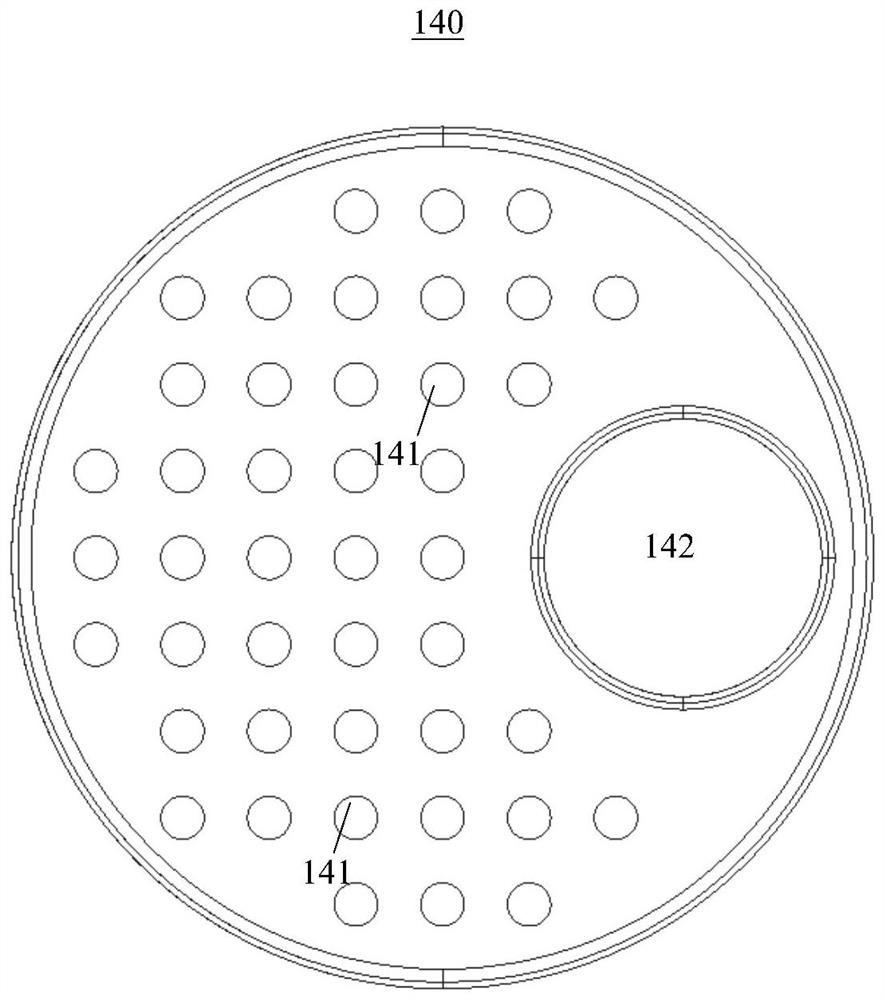

[0021] figure 1 An engine exhaust gas treatment system 100 integrated with a sound-absorbing structure according to an embodiment of the present application is schematically shown. In the context of the present application, engine exhaust gas treatment system 100 may be an exhaust gas treatment system of an engine of a motor vehicle, in particular a diesel vehicle. The engine exhaust gas treatment system 100 is connected in series in the exhaust pipe 10 of a motor vehicle, especially a diesel vehicle, and constitutes a part of the exhaust pipe 10 . In the context of this application, the term "connected in series" means that the engine exhaust treatment system 100 has internal passages through which gases can flow in series with the remaining sections of the exhaust pipe so that the engine exhaust gas flows through the entir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com