Fireproof and heat-insulating safe and manufacturing process thereof

A manufacturing process and technology of safes, applied in safes, special surfaces, pre-treated surfaces, etc., can solve the problem that safes do not have fire protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

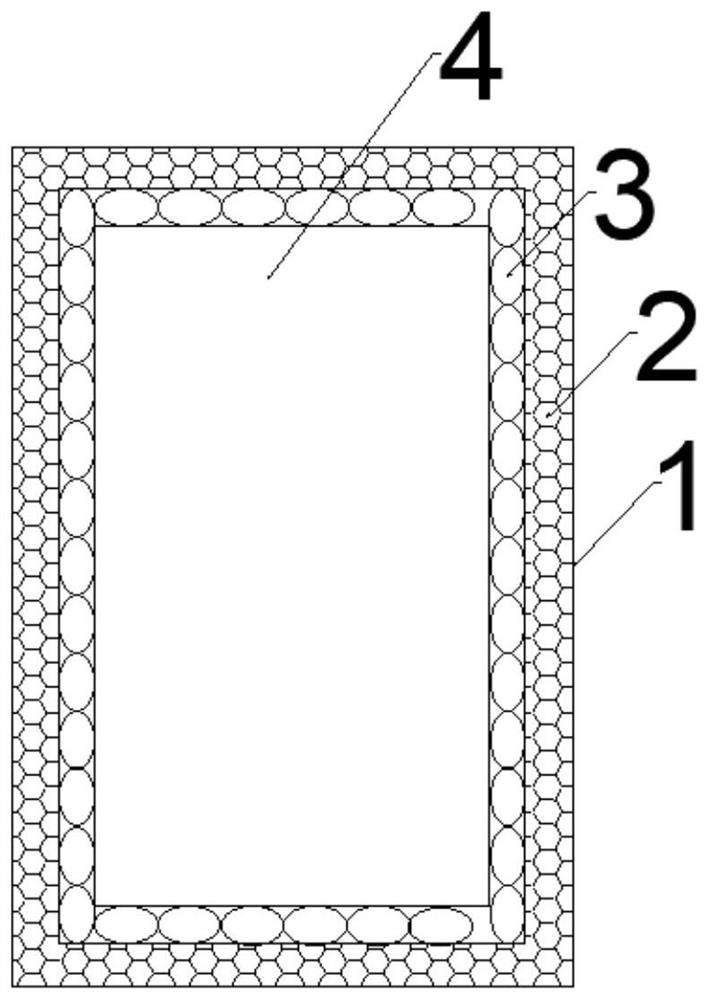

[0032] A fire-proof and heat-insulating safe, comprising a cabinet body 1, on which there is a fire-proof and heat-insulating cavity 2 and a storage cavity 4, the fire-proof and heat-insulating cavity 2 is provided with a fire-proof and heat-insulating material, and the fire-proof and heat-insulating material Including the following raw materials: matrix material, flame retardant and porous carbon material.

[0033] As a preferred embodiment of the present invention, it also has the following additional technical features:

[0034] The base material is metal foam.

[0035] The flame retardant uses sodium bicarbonate and / or rock powder.

[0036] The mass ratio of the matrix material, flame retardant and porous carbon material is 1:0.05-0.1:0.1-0.3.

[0037] The thickness of the fire-proof and heat-insulating cavity 2 is 0.1-3 cm, preferably 2 cm.

[0038] A number of evenly distributed arched spheres 3 are arranged between the fire-proof and heat-insulating chamber 2 and the...

no. 2 example

[0040] A manufacturing process of a fire-resistant and heat-insulated safe, comprising the following steps:

[0041] Step 1: making a cabinet body with a fire-proof and heat-insulating cavity;

[0042] Step 2: Make fire-proof and heat-insulating materials, and place them in the fire-proof and heat-insulation cavity in step 1. The manufacturing process of fire-proof and heat-insulating materials is as follows:

[0043] First prepare the flame retardant into a solution, then place the porous carbon material in the solution for the first impregnation, continue to add matrix materials into the solution, perform the second impregnation, and dry to obtain the fireproof and heat insulating material.

[0044] Specifically, the base material is iron-nickel foam metal, and the porous carbon material can be activated carbon or coke.

[0045] In the second step, the first impregnation and / or the second impregnation is ultrasonic impregnation.

[0046] In the described step 2, the drying...

Embodiment 201

[0050] A manufacturing process of a fire-resistant and heat-insulated safe, comprising the following steps:

[0051] Step 1: making a cabinet body with a fire-proof and heat-insulating cavity;

[0052] Step 2: Make fire-proof and heat-insulating materials, and place them in the fire-proof and heat-insulation cavity in step 1. The manufacturing process of fire-proof and heat-insulating materials is as follows:

[0053] First prepare the flame retardant into a solution, specifically adding the flame retardant to water, then place the porous carbon material in the solution for the first 3 hours of immersion, continue to add matrix materials to the solution, and perform the second immersion for 5 hours, after drying A fire-proof and heat-insulating material is prepared.

[0054] Described flame retardant adopts sodium bicarbonate.

[0055]The mass ratio of the matrix material, flame retardant and porous carbon material is 1:0.05:0.1.

[0056] Specifically, the base material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com