A method for preparing conductive material of polyester-cotton fabric modified by metal-organic framework compound

A technology of metal-organic frameworks and conductive materials, which is applied in the fields of plant fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of harsh and complex process conditions and complex processes, achieve good flexibility and air permeability, and have good application performance and good performance. The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

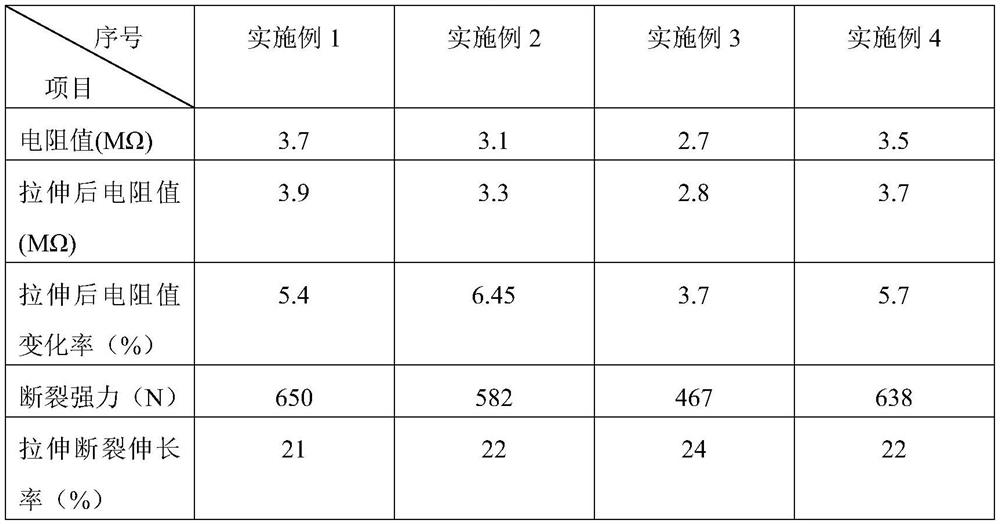

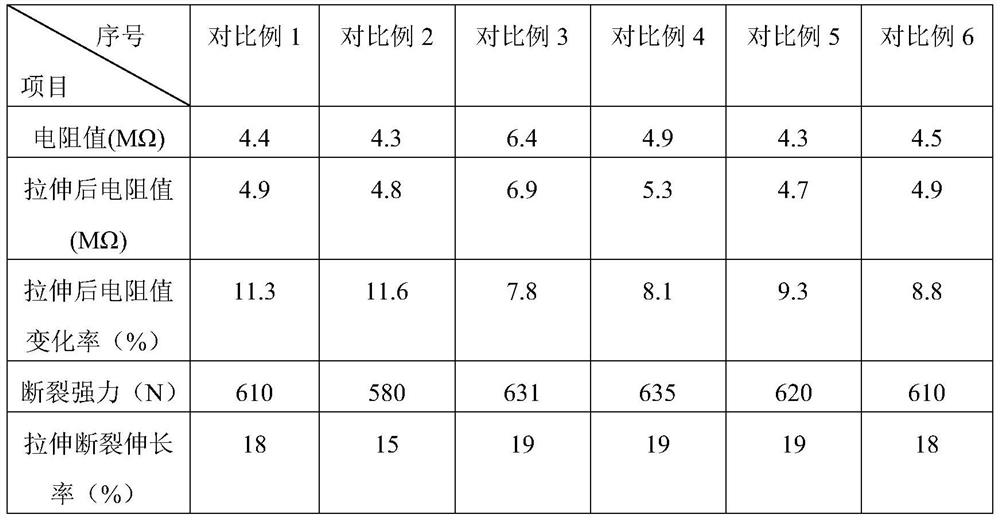

Examples

Embodiment 1

[0020] (1) Take a piece of 1.5cm×1cm woven polyester-cotton fabric, wherein the polyester-cotton component ratio is 50:50, under the condition of applying tension, place 7mol / L sodium hydroxide, 7mol / L sodium chloroacetate and In a mixed solution of 0.3mol / L disodium edetate, the volume of the mixed solution is 100ml, soak for 5min;

[0021] (2) 0.04mol / L copper trifluoroacetylacetonate and 0.02mol / L 2,3,6,7,10, 1mL each of 11-hexahydroxytriphenylenebenzene (HHTP), and spray the above two solutions on the prepared carboxymethylated polyester-cotton fabric in sequence at 85°C until it is evenly coated with polyester-cotton fabric. For fabrics, dry for 30 minutes before spraying another solution.

[0022] (3) The polyester-cotton fabric obtained above was washed once with deionized water and acetone respectively, and soaked in 40° C. deionized water for 5 days, replaced with deionized water every 2 days, and then soaked with acetone for 8 days. The acetone is replaced once eve...

Embodiment 2

[0026] (1) Take a piece of knitted polyester-cotton fabric of 1.5cm×1cm, wherein the polyester-cotton component ratio is 20:80, place it in 6mol / L sodium hydroxide, 6mol / L sodium chloroacetate and 0.1mol under the condition of tension / L mixed solution of disodium edetate, the volume of the mixed solution is 200ml, soak for 1min;

[0027] (2) Deionized water and dimethylformamide are prepared with 0.02mol / L copper oxalate and 0.01mol / L 2,3,6,7,10,11-hexahydroxytriphenylenebenzene at a volume ratio of 1:1. 1mL, spray the above two solutions on the prepared carboxymethylated polyester-cotton fabric in sequence at 60°C until it is evenly coated on the polyester-cotton fabric, dry for 30min, and then spray another solution .

[0028] (3) The polyester-cotton fabric obtained above was washed 3 times with deionized water and ethanol respectively, and soaked in 50°C deionized water for 1 day, replaced with deionized water every 1 day, and then soaked with ethanol for 5 days. Ethano...

Embodiment 3

[0032](1) Take a piece of 1.5cm×1cm woven polyester-cotton fabric, in which the polyester-cotton component ratio is 50:100, place it in 8mol / L sodium hydroxide, 8mol / L sodium chloroacetate and 0.5 mol / L mixed solution of disodium edetate, the volume of the mixed solution is 300ml, soak for 10min;

[0033] (2) 0.06mol / L copper acetate and 0.03mol / L 2,3,6,7,10,11-hexahydroxytriethylene oxide were respectively prepared in deionized water and 1-methyl-2-pyrrolidone with a volume ratio of 5:1 as the solvent 1mL each of phenylbenzene, spray the above two solutions on the prepared carboxymethylated polyester-cotton fabric in sequence at 95°C until it is evenly coated on the polyester-cotton fabric, dry for 30min and then spray Another solution.

[0034] (3) The polyester-cotton fabric obtained above was washed 5 times with deionized water and methanol respectively, and soaked in 20°C deionized water for 3 days, replaced with deionized water every 1 day, and then soaked with methanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com