Starch-based plastic tableware and production method thereof

A technology for starch-based plastics and tableware, which is applied in the field of degradable tableware preparation and can solve the problems of poor toughness, poor stability, and difficulty in processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Dissolution of starch in DMSO solvent

[0041] Measure 100mL DMSO into a 250mL three-necked bottle, dry the cornstarch at 60°C for 24h in vacuum, weigh 20.0g of dried cornstarch and add it to the three-necked bottle, heat at 80°C until the starch is completely dissolved, and the time for heating to dissolve is 1h. Remove from heat and cool to room temperature.

[0042] 2) preparation of starch acetoacetate

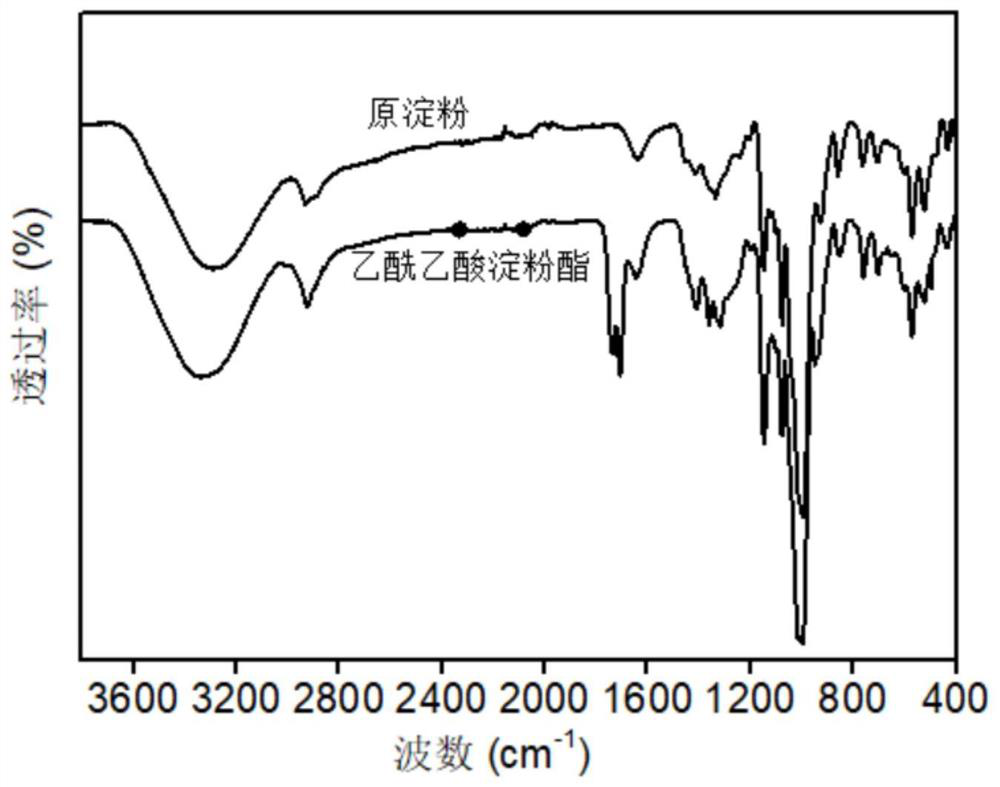

[0043] Heat the starch solution dissolved in step 1) to 110°C, protect it with nitrogen, weigh 39.0g of tert-butyl acetoacetate and add it dropwise into a three-necked flask. The reaction mixture was added dropwise into an ethanol solvent to precipitate, the product was washed three times with ethanol solvent, filtered with suction, and dried in vacuum at 60° C. for 24 hours to obtain the product starch acetoacetate. The degree of substitution of the starch acetoacetate prepared by this method is 0.65, and the infrared spectrum is as follows: figure 1 Shown, t...

Embodiment 2

[0047] 1) the dissolving of starch in DMSO solvent is with example 1;

[0048] 2) preparation of starch acetoacetate

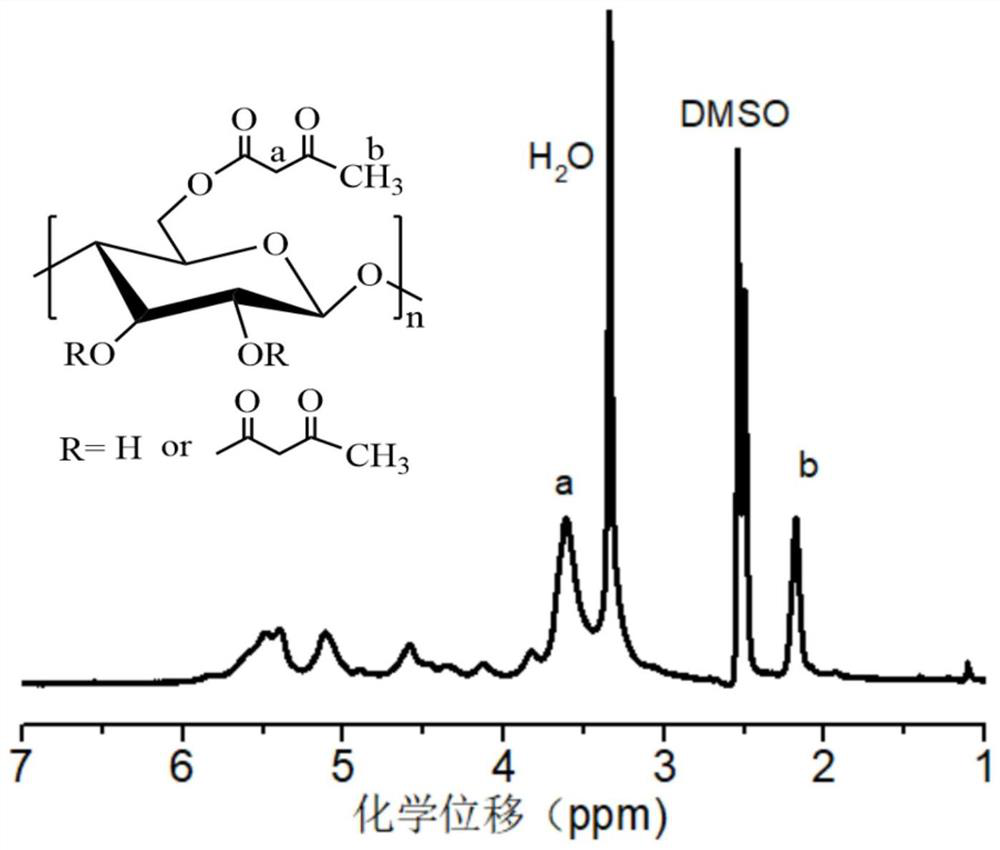

[0049] Heat the starch solution dissolved in step 1) to 110°C, protect with nitrogen, weigh 58.5g of tert-butyl acetoacetate and add it dropwise into a three-necked flask. The reaction mixture was added dropwise into an ethanol solvent to precipitate out, and the product was washed three times with an ethanol solvent, filtered with suction, and vacuum-dried at 60° C. for 24 hours to obtain starch acetoacetate product. The degree of substitution of starch acetoacetate prepared by the method is 1.38, and the nuclear magnetic spectrum of starch acetoacetate is as follows image 3 shown.

[0050] 3) Preparation of starch-based plastic tableware

[0051] Put the starch acetoacetate in step 2) into an extruder, mix evenly at 150° C. for 10 minutes, then melt and extrude it and inject it into a mold, and cool to room temperature to obtain starch-based plastic tabl...

Embodiment 3

[0053] 1) the dissolving of starch in DMSO solvent is with example 1;

[0054] 2) preparation of starch acetoacetate

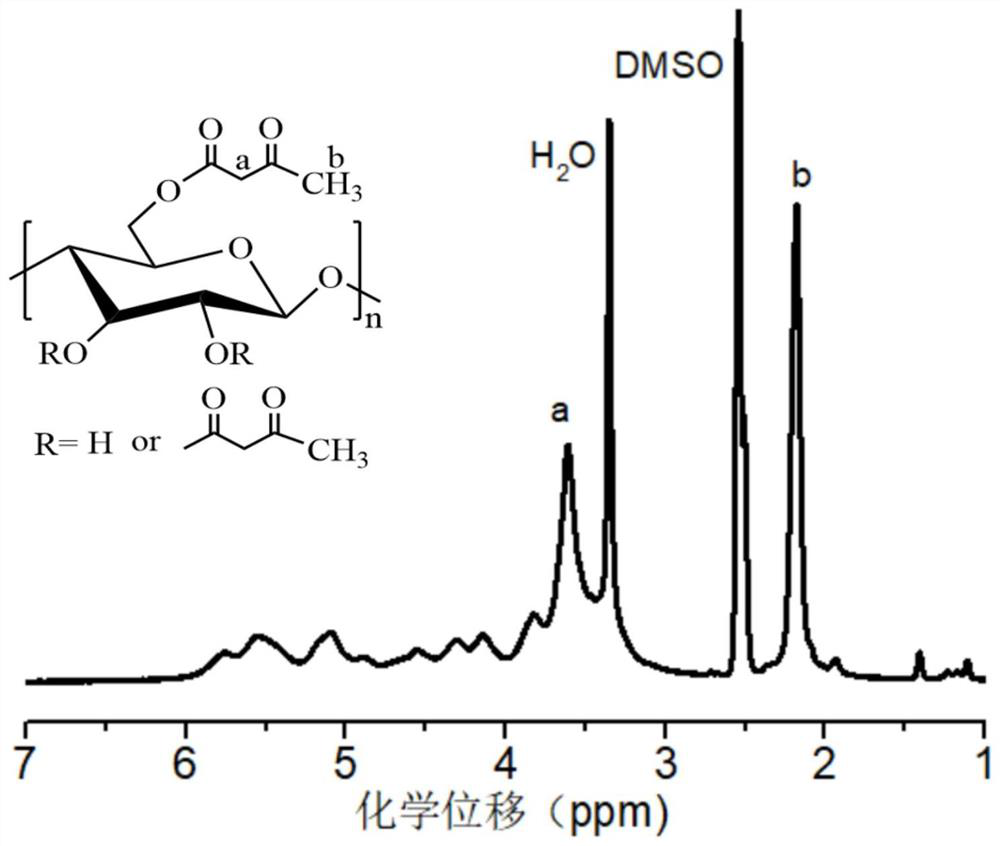

[0055] Heat the starch solution dissolved in step 1) to 110°C, protect it with nitrogen, weigh 78.0g of tert-butyl acetoacetate and add it dropwise into a three-necked flask. The reaction mixture was added dropwise into an ethanol solvent to precipitate, and the product was washed three times with an ethanol solvent, filtered with suction, and vacuum-dried at 80° C. for 12 hours to obtain the product starch acetoacetate. The degree of substitution of starch acetoacetate prepared by the method is 1.80, and the nuclear magnetic spectrum of starch acetoacetate is as follows Figure 4 shown.

[0056] 3) Preparation of starch-based plastic tableware

[0057] Put starch acetoacetate in step 2) into an extruder and mix uniformly at 140° C. for 10 minutes, then melt and extrude it into a mold, and cool to room temperature to obtain starch-based plastic tableware. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com