Carving machine management control method and system based on asynchronous receiving and dispatching framework

An asynchronous transceiver and engraving machine technology, which is applied in the fields of engraving, decorative arts, and processing models, can solve the problems of high jade processing costs, increased time costs, management costs, and human resource costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

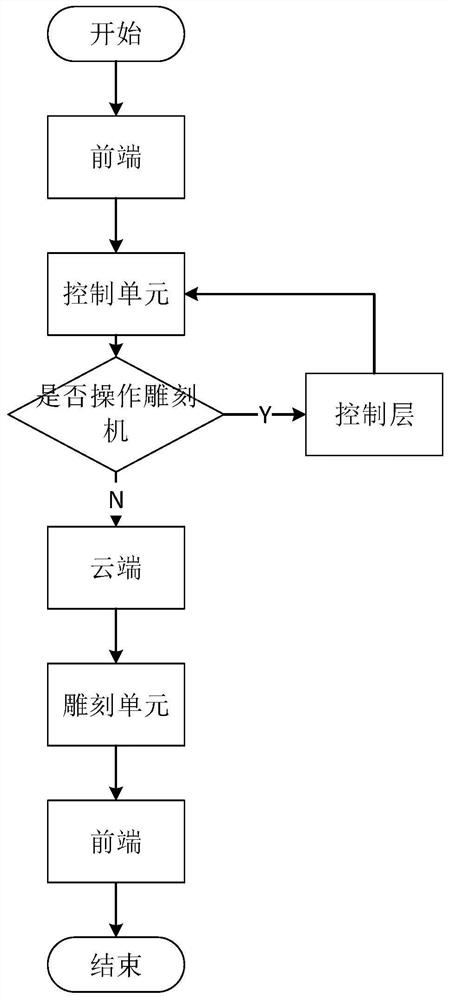

[0033] figure 1 A schematic flowchart of an engraving machine management and control method based on an asynchronous transceiver framework provided by an embodiment of the present invention, as shown in figure 1 As shown, the method includes:

[0034] Step 1: Each factory front-end sends a request to the intranet network card of the asynchronous transceiver device through the intranet; that is, Party A publishes the processing code on the cloud and issues tasks to the factory, and the factory technicians execute this through the factory front-end Invent technical solutions.

[0035] Step 2: The asynchronous transceiver device sends the received request to the engraving machine control layer in the internal network through the internal network card, so that the engraving machine control layer sends a preliminary instruction to the engraving machine; after the engraving machine receives the preliminary instruction, the machine is activated. Wake up or reset and wait for proces...

Embodiment 2

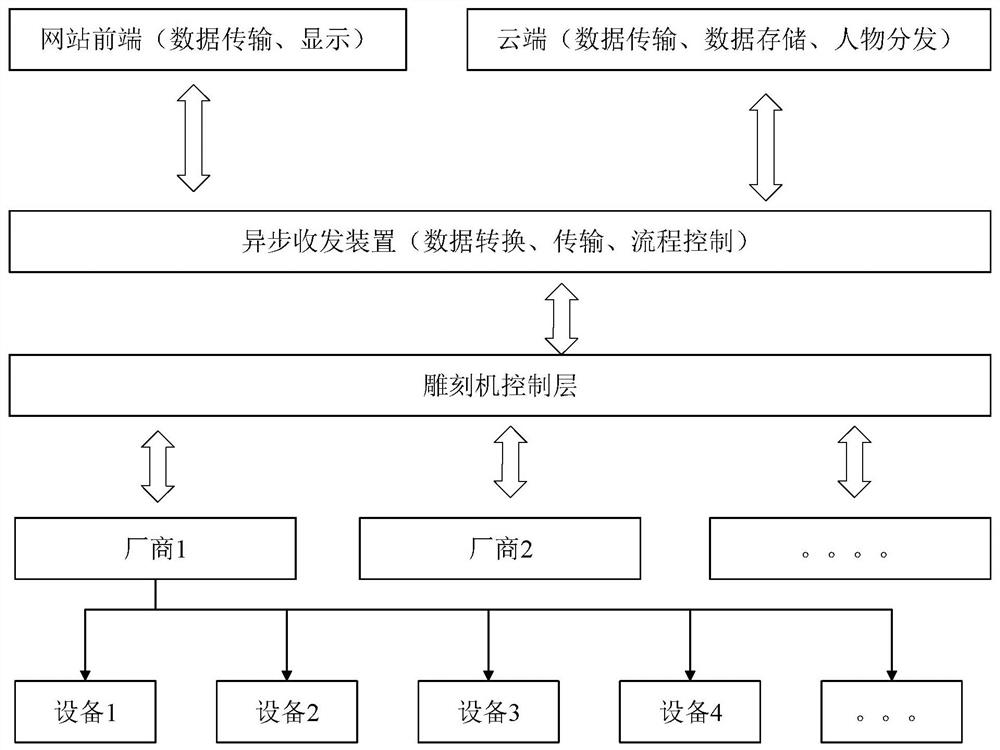

[0049] figure 2 A schematic structural diagram of a system provided by an embodiment of the present invention, such as figure 2 As shown, based on Embodiment 1 of the present invention, the present invention also provides an engraving machine management and control system based on an asynchronous transceiver framework.

[0050] The front end of the factory is used to send requests to the asynchronous transceiver device through the intranet;

[0051] The asynchronous transceiver device is used to send the request to the engraving machine control layer through the internal network, so that the engraving machine control layer sends a preliminary instruction to the engraving machine, and sends feedback information for the request to the cloud through the external network;

[0052] The cloud is used to send processing instructions to the asynchronous transceiver device through the external network, wherein the processing instructions include processing codes;

[0053] The async...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com