Low-alkali separation method for high-sulfur copper-zinc ore

A separation method and technology for copper-zinc ore, applied in the direction of solid separation, flotation, etc., can solve the problems of poor quality of concentrate products, increased production costs, running grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] figure 1 Be the method flowchart of the present embodiment, wherein have: 1-calcium oxide dry powder; 2-sodium metabisulfite dry powder; 3-copper efficient collector.

[0030] A kind of low-alkali separation method of high-sulfur copper-zinc ore provided by the present embodiment, such as figure 1 shown, including the following steps:

[0031] S1. Raw ore grinding: Put the raw ore and water into the mill for grinding at a mass ratio of 5:3, add calcium oxide dry powder in the mill, adjust the pH value of the pulp to 7.5-8; grind to the final product Parts with a fineness of -75μm account for 80-85% of the total mass;

[0032] S2. Copper roughing: put the grinding product obtained in step S1 into the flotation machine, add calcium oxide dry powder in the flotation machine, adjust the pH value of the pulp to 9-9.5, and stir for 3 minutes; then add zinc inhibitor solids in sequence Sodium pyrosulfite powder and high-efficiency copper collector are stirred for 3 minutes ...

Embodiment 2

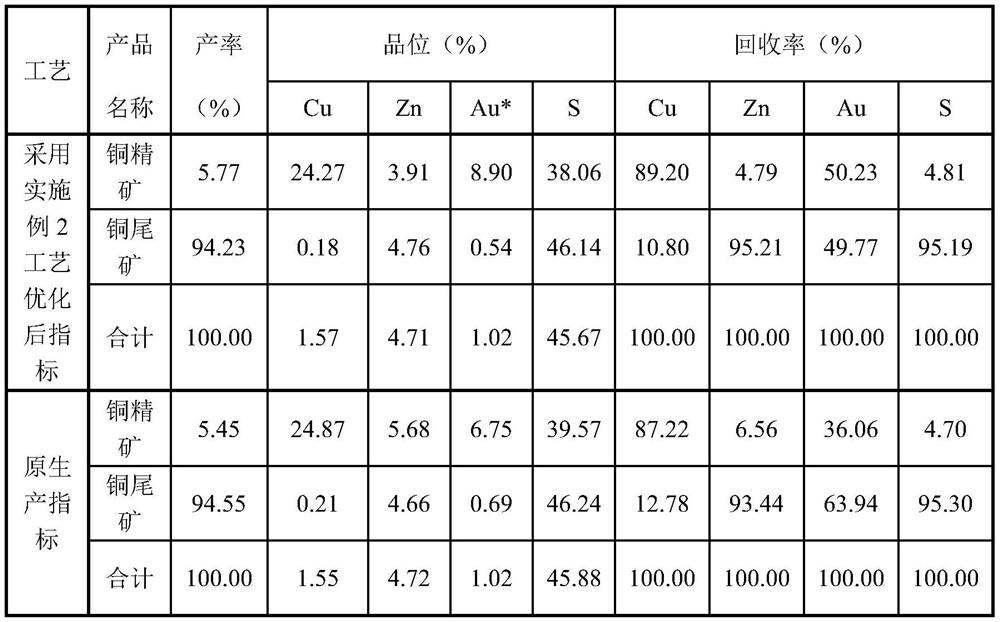

[0038]Mineral raw materials: The raw ore of a foreign high-sulfur copper-zinc polymetallic mine is taken. The ore contains 1.55% Cu, 4.70% Zn, 1.02g / t Au, 42.34g / t Ag, and 45.67% S by mass percentage. The main useful minerals of raw ore are chalcopyrite and sphalerite, other sulfides are mainly pyrite, and the content of pyrite is as high as 85.01%. The original production process mainly has problems such as poor copper-zinc separation effect and poor pyrite inhibition effect. Adopt the process described in embodiment 1 to process this ore, concrete steps comprise:

[0039] S1. Raw ore grinding: Put the raw ore and water into the mill for grinding according to the mass ratio of 5:3, add calcium oxide dry powder in the mill, and the dosage is 1000g / t per ton of raw ore, and adjust the pulp The pH value is up to 8; after grinding, the part of the grinding product with a fineness of -75μm accounts for 80% of the total mass;

[0040] S2. Copper roughing: put the grinding product ...

Embodiment 3

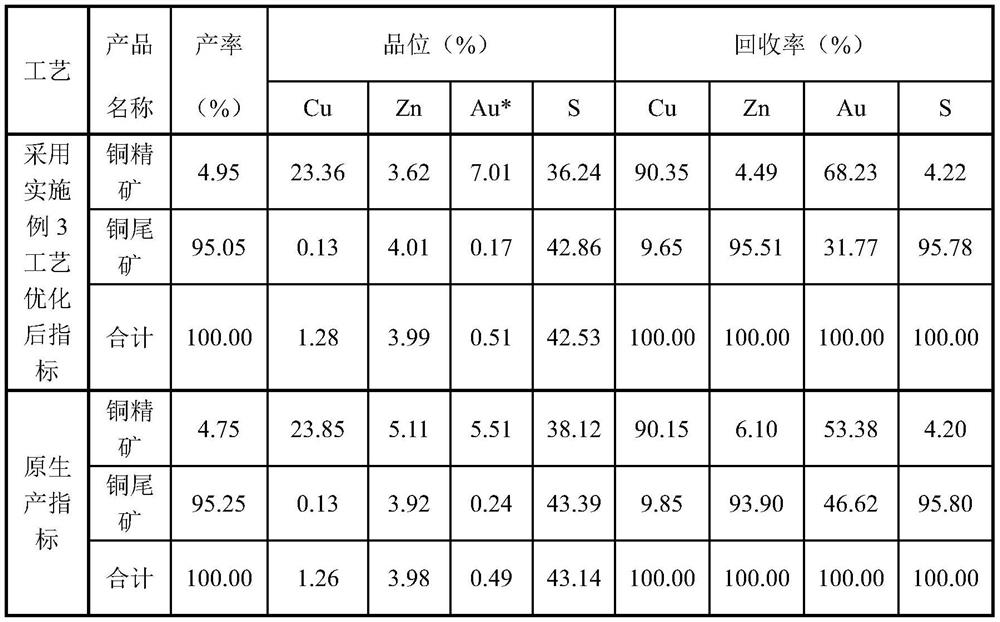

[0048] The raw ore used in this example differs from the raw ore in Example 2 in that it contains 1.28% Cu, 3.99% Zn, 0.5g / t Au, 43.13g / t Ag, and 42.53% S by mass percentage.

[0049] Adopt the process described in embodiment 1 to process this ore, concrete steps comprise:

[0050] S1. Raw ore grinding: put the raw ore and water into the mill for grinding at a mass ratio of 5:3, add calcium oxide dry powder into the mill, and adjust the pH value of the pulp to 7.5; after grinding, the ground product The part with a fineness of -75μm accounts for 85% of the total mass;

[0051] S2. Copper roughing: feed the grinding product obtained in step S1 into the flotation machine, first add calcium oxide dry powder in the flotation machine, stir for 3 minutes, and adjust the pH value of the slurry to 9.5; then zinc inhibitor solid sodium metabisulfite Powder and high-efficiency copper collector are stirred for 3 minutes and 2 minutes respectively to obtain copper rough concentrate and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com