Compound preparation for improving quality of upper tobacco leaves of flue-cured tobacco and preparation method and application of compound preparation

A compound preparation and tobacco leaf technology, applied in the field of tobacco production, can solve the problems of scattered application results, lack of technical level, strong pertinence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Compound preparation preparation: including the following steps,

[0036] S1: Activation culture of bacterial strains. The Bacillus cereus 4-a and Bacillus cereus 4-d obtained by screening were respectively activated and cultured on the activation plate medium.

[0037]Specifically, in a sterile working environment, use a sterilized spatula to scrape a small amount of bacteria from the slant culture medium in a closed test tube of the preserved strain, and apply it to an activated plate culture in a sterile petri dish with a three-section line separation method. On the base, grow to form a single colony. The formula of the activated plate medium is: 0.3% beef extract, 0.5% tryptone, 1% sodium chloride, 1.5% agar powder, adjust the pH value to 7.2 after making up the volume with distilled water, and heat it under high pressure at 121 ℃ Sterilize for 10 minutes, pour into a sterile petri dish to solidify.

[0038] S2: Expansion culture of bacterial strains, the single co...

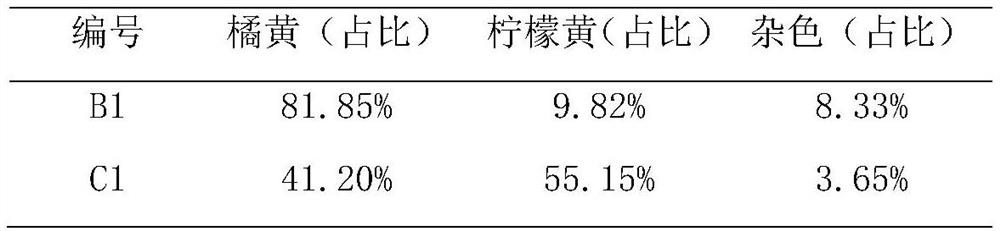

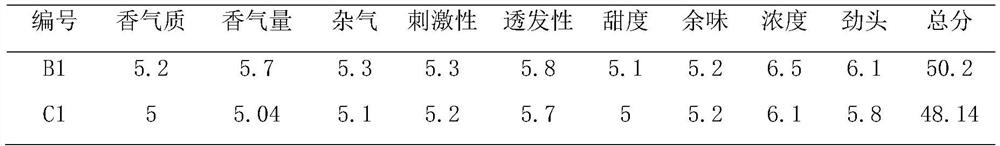

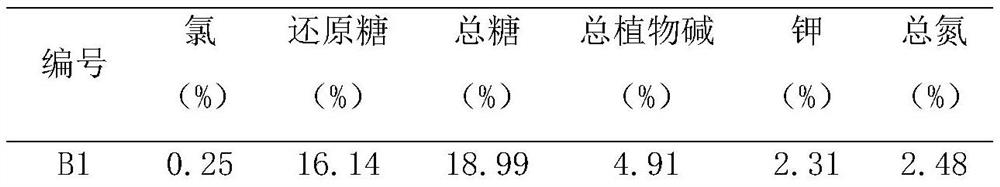

Embodiment 2

[0060] The difference from Example 1 is that during the preparation of the compound preparation, tryptone is not contained in the physiological saline of the resuspended bacteria of the inoculum 1 and the inoculum 2; The volume ratio of body, enzyme preparation solution, and inorganic salt solution auxiliary agent is 1.2:10:38:15; during the baking process, on the basis of the local "three-stage six-step" flue-cured tobacco baking process in Pengshui, Chongqing, the yellowing period The initial temperature was lowered by 4°C, and the yellowing period was prolonged for 12 hours. The number of the treated sample added with the compound preparation working solution is B2, and the number of the blank control sample added with the same amount of water is C2. See Table 5 for the grade structure of the cured tobacco leaf samples, Table 6 for the sensory evaluation results of the sample cigarettes, and Table 7 and Table 8 for the routine chemical composition test results and chemical ...

Embodiment 3

[0074] The difference from Example 1 is that during the preparation of the compound preparation, before the bacteria were collected by centrifugation, the counts of live bacteria in the bacterial suspension of the two bacterial strains all reached 10. 9 pcs / ml; when preparing the stock solution of the compound preparation, the volume ratio of the first inoculum, the second inoculum, the enzyme preparation solution, and the inorganic salt solution auxiliary agent is 1.1:12:35:15; the inorganic salt solution used as the auxiliary agent at the same time The concentration is 0.05%; the neutral protease that makes up the enzyme preparation: α-amylase: cellulase: pectinase: β-glucanase=9:52:1.2:17:10; during the baking process, in Chongqing Based on the local "three-stage and six-step" flue-cured tobacco curing process in Pengshui, the initial temperature of the yellowing period is reduced by 2°C, and the temperature stabilization period of the yellowing period is extended to 18 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com