Special-shaped deep-cavity hot-forging precision coupler knuckle die and processing method thereof

A deep cavity, hot forging technology, used in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., to improve production efficiency and overcome quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

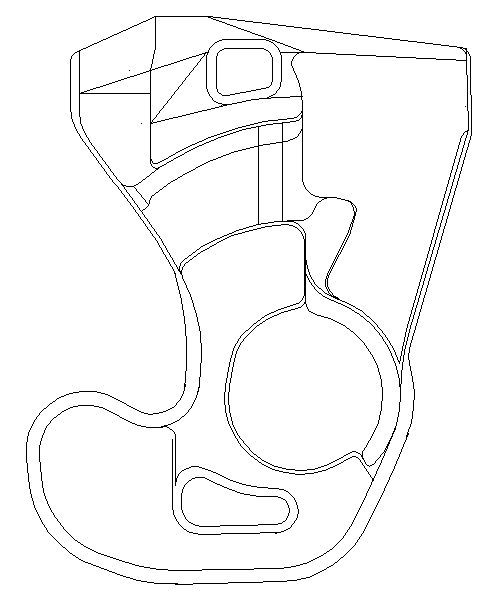

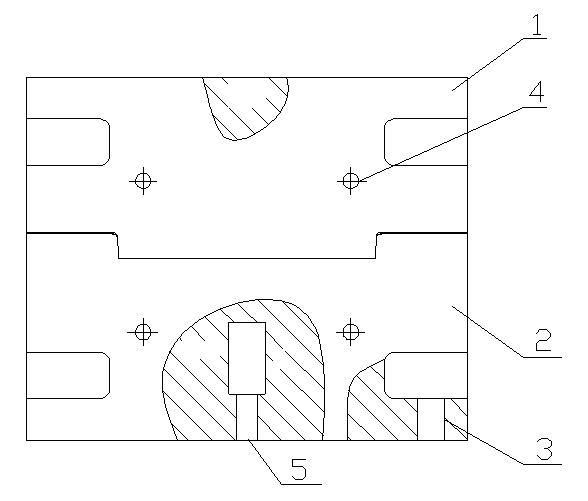

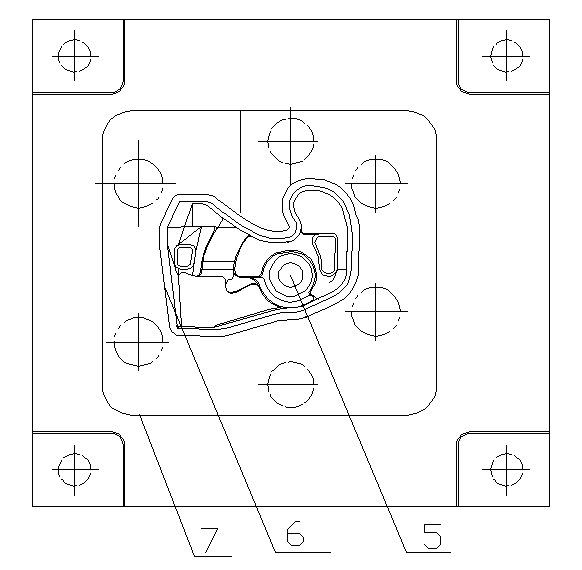

[0011] The special-shaped deep cavity hot forging precision knuckle mold of the present invention comprises an upper mold and a lower mold, the template 1 of the upper mold and the template 2 of the lower mold are both cuboids, the two are movably connected, and the cavity 6 of the upper and lower molds has the same shape and size , the shape of the cavity is the same as that of the knuckle, and the cavity is located in the middle of the template. Wherein, the die cavity 6 is formed by closing several sections of arcs and straight lines, forming the shape of the knuckle.

[0012] The material of the upper and lower molds is mold steel 5CrNiMo, the size of the upper template is 850mm×800mm×350mm, and the size of the lower template is 850mm×800mm×450mm. Grooves 7 are set on the contact surfaces of the upper and lower templates around the cavity, the grooves are 3 mm lower than the parting surface, and the length and width are 550 mm × 500 mm, which are used as unloading troughs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com