Control method for online predication of surface crack of continuous casting sheet billet

A surface crack and control method technology, which is applied in the field of steelmaking and continuous casting, can solve problems such as product scrapping, achieve high prediction accuracy, reduce the occurrence of quality defects, and improve the quality of slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

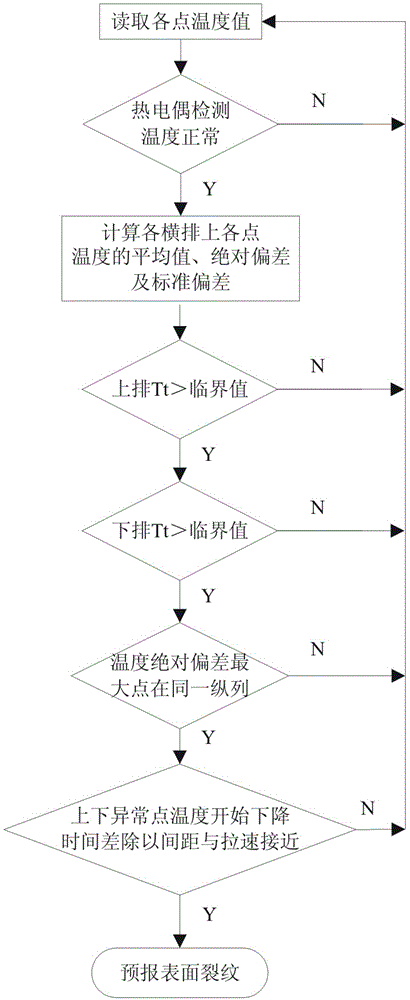

[0036] The following is attached figure 1 and 2 The present invention will be further described with following examples, but the present invention is not limited.

[0037] The present invention will be further described below in conjunction with the examples, but the present invention is not limited.

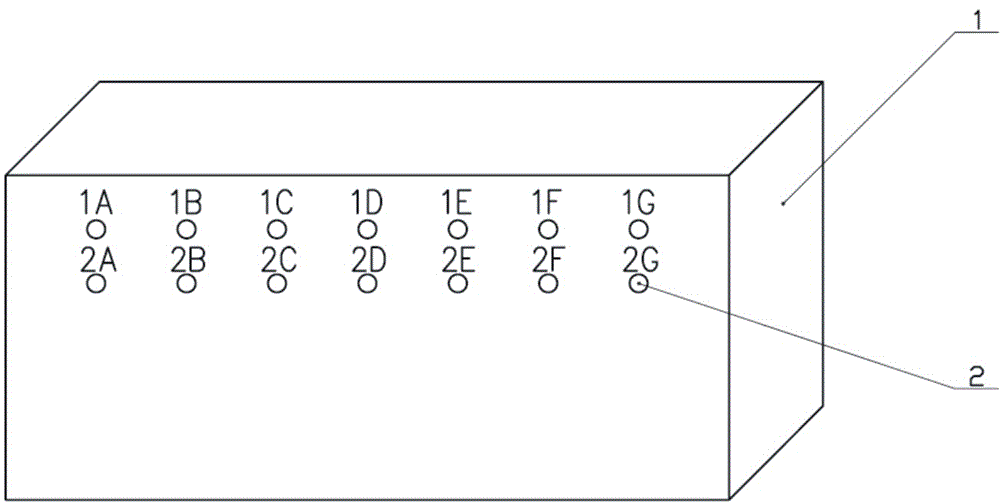

[0038] refer to figure 1 , in the crystallizer, 2 horizontal rows and 8 vertical rows of thermocouples are buried at even intervals below the molten steel level to form a temperature detection system (ie m=2, n=8), to confirm whether the temperature detection system is working normally, Then proceed as follows:

[0039] 1. Obtain the temperature value recorded by each row thermocouple through the temperature detection system (T 1 , T 2 ·····T 8 );

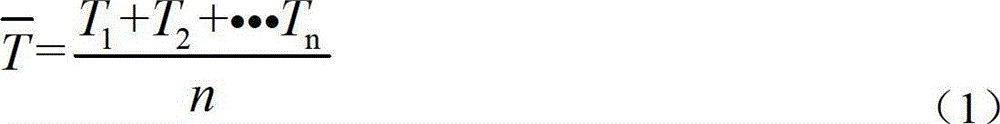

[0040] 2. Calculate the average value, absolute deviation and standard deviation of each temperature in the same row;

[0041] T ‾ = T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com