Metal alloy-carbon nanotube network macroscopic body composite material, preparation method and application thereof

A technology of carbon nanotubes and metal alloys, which is applied in the field of energy and cleanliness, can solve the problems of inability to ensure high utilization of nanocatalysts and high combination of carbon supports, reduced catalytic performance and anti-poisoning performance, and easy agglomeration and migration. Achieve excellent anti-methanol poisoning performance, strong binding force and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

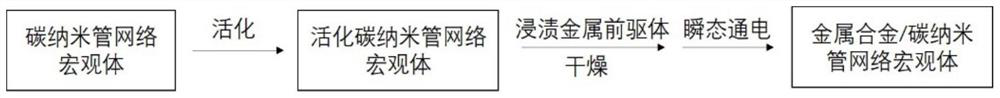

[0031] One aspect of the embodiments of the present invention provides a method for preparing a metal alloy-carbon nanotube network macroscopic body composite material, which includes:

[0032] (1) providing a carbon nanotube network macroscopic body, the carbon nanotube network macroscopic body contains iron as a trace impurity;

[0033] (2) Activating the carbon nanotube network macroscopic body;

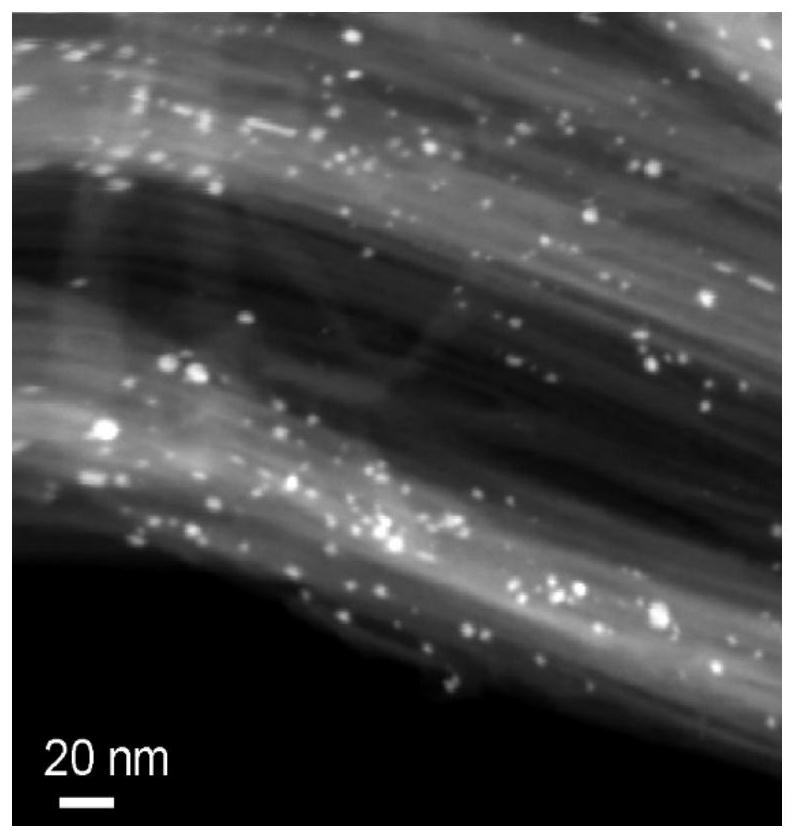

[0034] (3) Contacting the activated carbon nanotube network macroscopic body with the metal precursor solution, causing the iron element to undergo a displacement reaction with the metal precursor to generate an elemental metal combined with the elemental iron, the elemental metal It has oxygen reduction catalytic activity, followed by drying treatment;

[0035] (4) Transient electric heating is performed on the carbon nanotube network macroscopic body treated in step (3) to obtain a metal alloy-carbon nanotube network macroscopic body composite material.

[0036] In some typical ...

Embodiment 1

[0080] The preparation process of a metal alloy-carbon nanotube network macroscopic body composite material provided by this embodiment is as follows: figure 1 As shown, it includes the following steps:

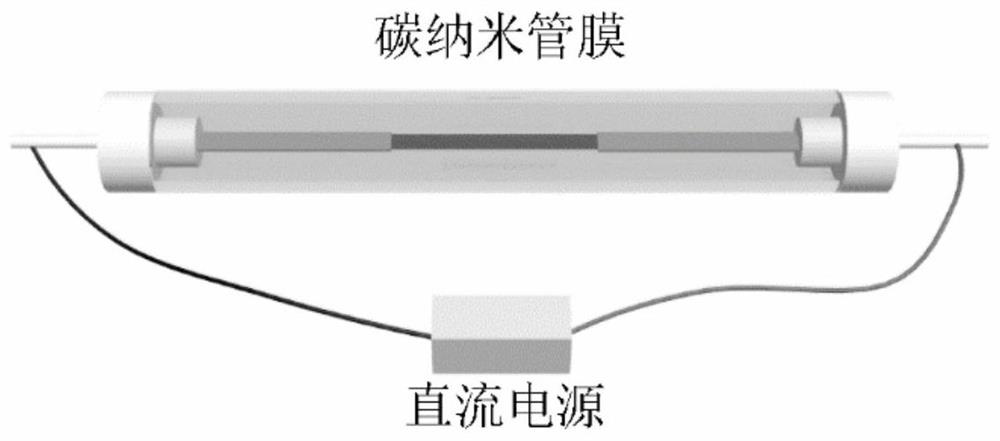

[0081] Step 1. Provide the carbon nanotube network macrobody prepared by floating chemical vapor deposition method, its preparation process is: the FCCVD tubular furnace device is heated to 1300 ℃, injects with syringe pump containing 2wt.% ferrocene and 0.4wt.% Thiophene solution in absolute ethanol at an injection rate of 20 mL h -1 , the carrier gas is Ar / H 2 Mixed gas, Ar flow rate 2200sccm, H 2 The flow rate is 2000sccm, the original CNT airgel is collected by the roller after floating out from the tail, sprayed with ethanol and infiltrated, and further compressed by the roller shaft to obtain a carbon nanotube network macroscopic body containing 5% iron impurity, and then electrochemically Activation treatment, including: using the carbon nanotube network macroscopic...

Embodiment 2

[0087] Step 1. Provide the carbon nanotube network macrobody prepared by floating chemical vapor deposition method, its preparation process is: the FCCVD tubular furnace device is heated to 1300 ℃, injects with syringe pump containing 2wt.% ferrocene and 0.4wt.% Thiophene solution in absolute ethanol at an injection rate of 20 mL h -1 , the carrier gas is Ar / H 2 Mixed gas, Ar flow rate 2200sccm, H 2 The flow rate is 2000 sccm, the original CNT airgel is collected by the roller after floating out from the tail, sprayed with ethanol and infiltrated, and further compressed with a roller to obtain a carbon nanotube network macroscopic body containing 1wt.% iron impurity, and then electrochemically activate it The treatment includes: using the carbon nanotube network macroscopic body as an anode, using a platinum sheet of the same area as a counter electrode, using a solution of 0.2g sodium hydroxide dissolved in 1mL water and 20mL ethanol as an electrolyte, and using a direct cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com