Method for enhancing hydrogel through microbial mineralization

A hydrogel and microbial technology, applied in the field of microbial mineralization to enhance hydrogel, can solve the problems of poor tensile strength effect, negative impact on strength, and high requirements for initiators, achieve good economic and social benefits, simple preparation process, Broaden the effect of application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

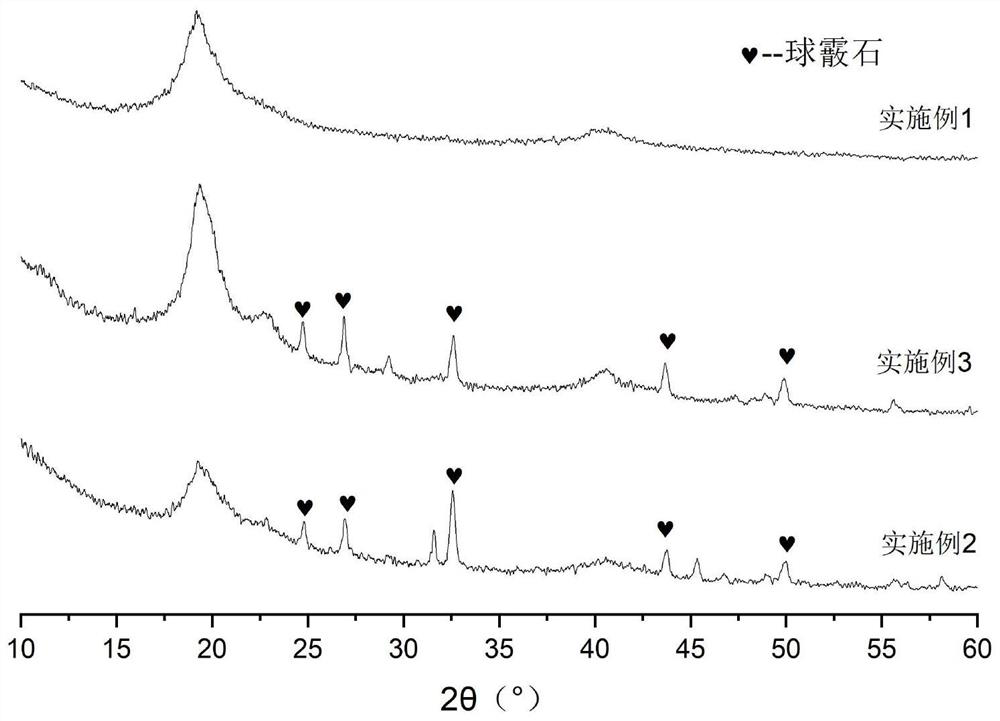

[0028] Embodiment 1 (blank group gel 1)

[0029] A method for hydrogel comprising the steps of:

[0030] (1) 1.8g of polyvinyl alcohol (PVA) particles were stirred in a high temperature (90-95°C) water bath for 2 hours and completely dissolved in deionized water to make a uniform and transparent PVA solution, and then 1.8g of urea and 3.33g of calcium chloride were dissolved in In the PVA solution, cool to room temperature to obtain a mixed solution, wherein the concentration of PVA is 6wt%, and the concentrations of urea and calcium chloride are 1M;

[0031] (2) Vacuum filter the mixed solution at 0.1MPa for 7min and 3 times, remove the air bubbles in it, and then injection mold it (the size of the mold is 90mm×10mm×3mm), then freeze at -18°C for 20h, then thaw at room temperature for 4h, alternately Cycle 3 times to obtain the blank gel.

[0032] The obtained blank group gel 1 was reacted at room temperature for 7 days, and the tensile strength of the hydrogel was tested b...

Embodiment 2

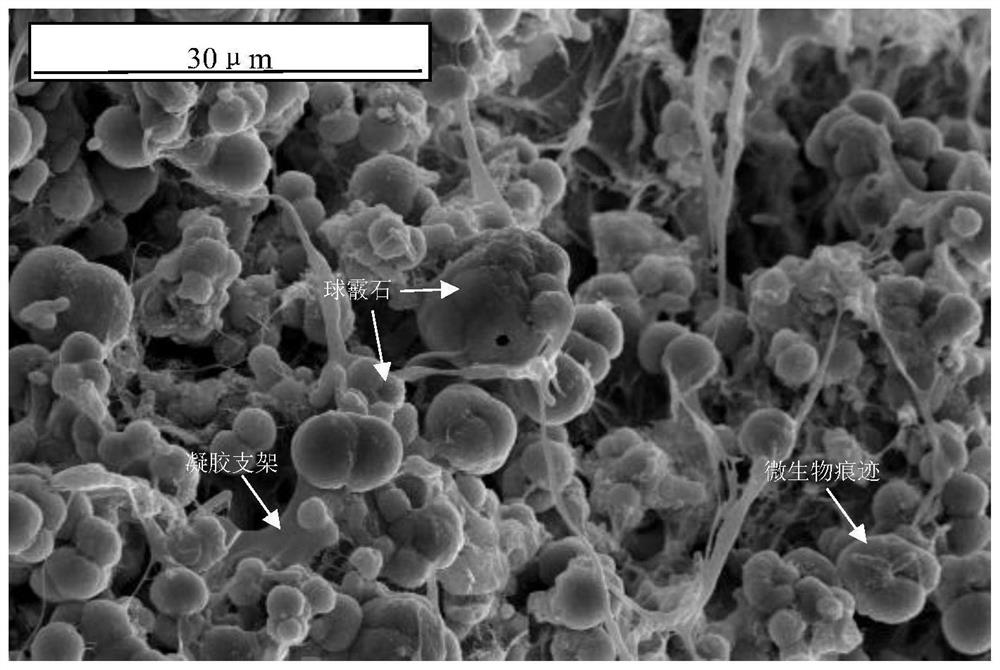

[0034] A method for microbial mineralization enhanced hydrogel, comprising the following steps:

[0035] (1) The medium used for the culture of urease bacteria is 0.13M Tris buffer, 10g / L (NH 4 ) 2 SO 4 , 20g / L yeast extract, sterilized at 120°C for 25min, then cooled to room temperature, inoculated with 1% volume of the original bacterial liquid, cultured on a shaker at 200rpm, 30°C for 24h to obtain mature bacterial liquid; then centrifuged at 8000rpm for 12min to obtain concentrated bacteria solution, the concentration of the bacterial solution was adjusted to 5×10 9 cell / mL, OD 600 The value is 1.9;

[0036] (2) 1.8g polyvinyl alcohol (PVA) particles were stirred in a high temperature (90-95°C) water bath for 3 hours and completely dissolved in deionized water to make a uniform and transparent PVA solution, and then 1.8g urea and 3.33g calcium chloride were dissolved in In the PVA solution, cool to room temperature, add 3mL of concentrated bacterial solution and stir ...

Embodiment 3

[0040] Compared with Example 2, only the dosage of the bacterial solution was changed to 5%, that is, the dosage of the concentrated bacterial solution was 1.5 mL. The prepared hydrogel was reacted at room temperature for 7 days, and the tensile strength of the hydrogel was tested by a universal testing machine. The loading speed was 100 mm / min, and the tensile strength of the sample was 0.51 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com