Preparation method of coronene compound

A compound and benzene technology, applied in the field of organic chemistry, can solve problems such as complicated operation, unsuitable for large-scale production, expensive raw materials, etc., and achieve the effect of simple preparation process, suitable for large-scale production, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

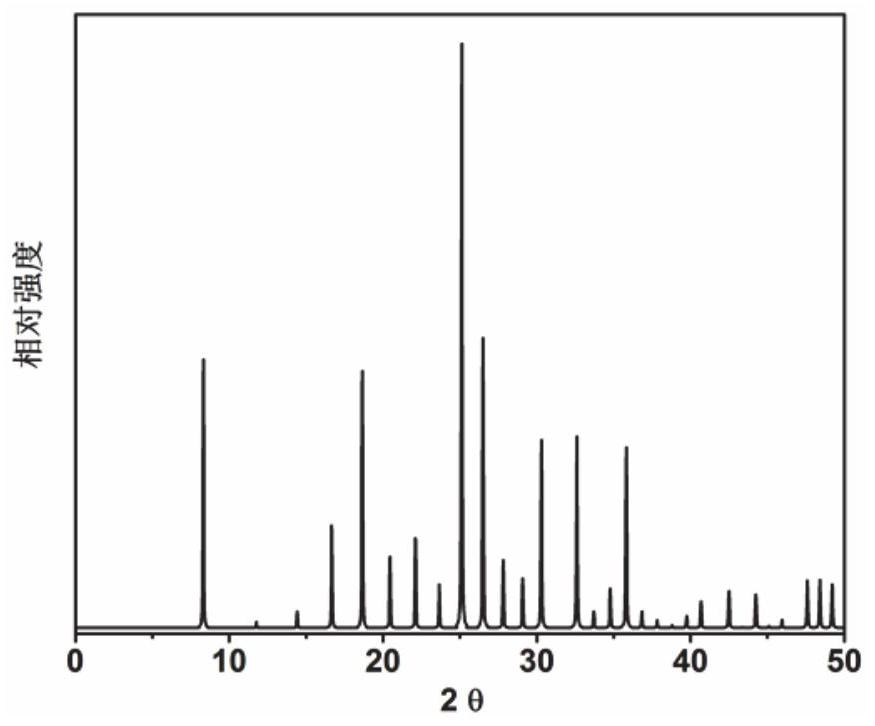

[0053] Embodiment 1: the synthesis of DNL-6 molecular sieve catalyst

[0054] Initial gel molar composition ratio 2N-methylbutylamine (as organic structure directing agent): 0.3SiO 2 : 0.4P 2 o 5 : 0.5Al 2 o 3 : 50H 2 O: 0.2 (20%) cetyltrimethylammonium bromide (as seed crystals) Mix measured amounts of organic structure directing agent, silica sol, phosphoric acid, aluminum isopropoxide, deionized water, and seed crystals in a beaker , fully stirred to form a gel, then loaded into a stainless steel autoclave lined with polytetrafluoroethylene, and rotated and crystallized at a constant temperature of 200°C at a speed of 75r / min for 24h. After crystallization, use a centrifuge at 3000 rpm for 3 minutes, wash the separated solid product with deionized water to neutrality, and dry it overnight in air at 120°C. The results of XRD analysis are as follows: figure 1 shown. From the results in Figure 1, it can be seen that the synthesized product is the raw powder of DNL-6 mol...

Embodiment 2

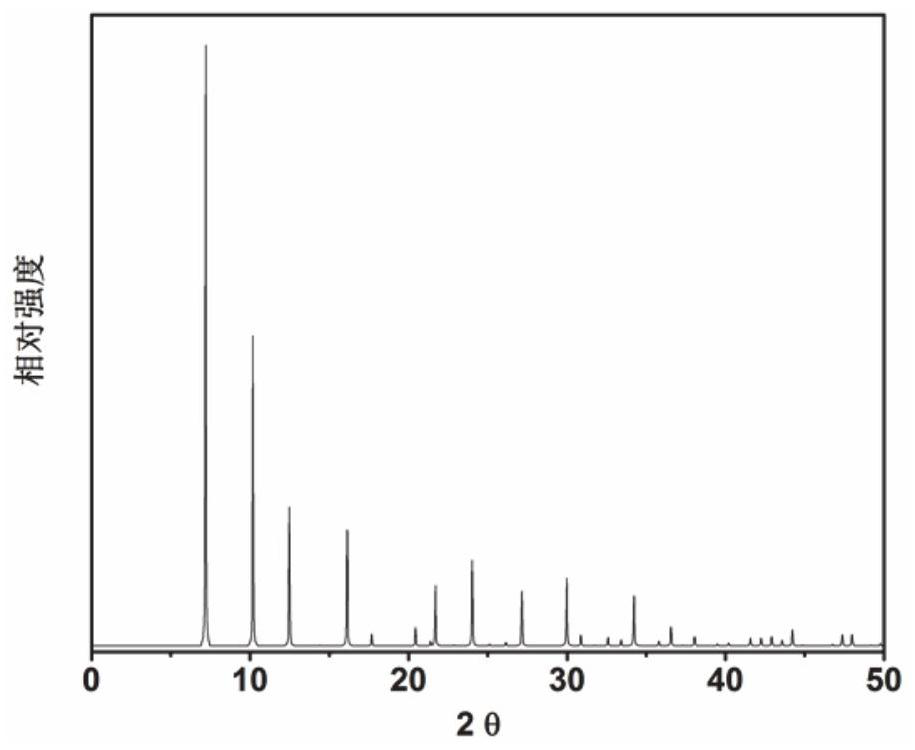

[0055] Embodiment 2: the synthesis of SAPO-42 molecular sieve catalyst

[0056] Based on the initial gel molar composition ratio of 1.85 2,2-dimethyl-2,3-dihydro-1H-phenyl[de]isoquinoline (as an organic structure-directing agent): 0.296SiO 2 : 0.85P 2 o 5 : 1Al 2 o 3 : 60H 2 O Mix the metered organic structure-directing agent, silica sol, phosphoric acid, pseudoboehmite and deionized water in a beaker, stir well to form a gel, and then put it into a stainless steel autoclave lined with polytetrafluoroethylene. Constant temperature crystallization at 175℃ for 120h. After crystallization, use a centrifuge at 3000 rpm for 3 minutes, wash the separated solid product with deionized water until it is neutral, and dry it overnight in air at 100°C. The results of XRD analysis are as follows: figure 2 shown. from figure 2 It can be seen from the results that the synthesized product is SAPO-42 molecular sieve raw powder, and the raw powder was calcined at 600°C for 5 hours to ...

Embodiment 3

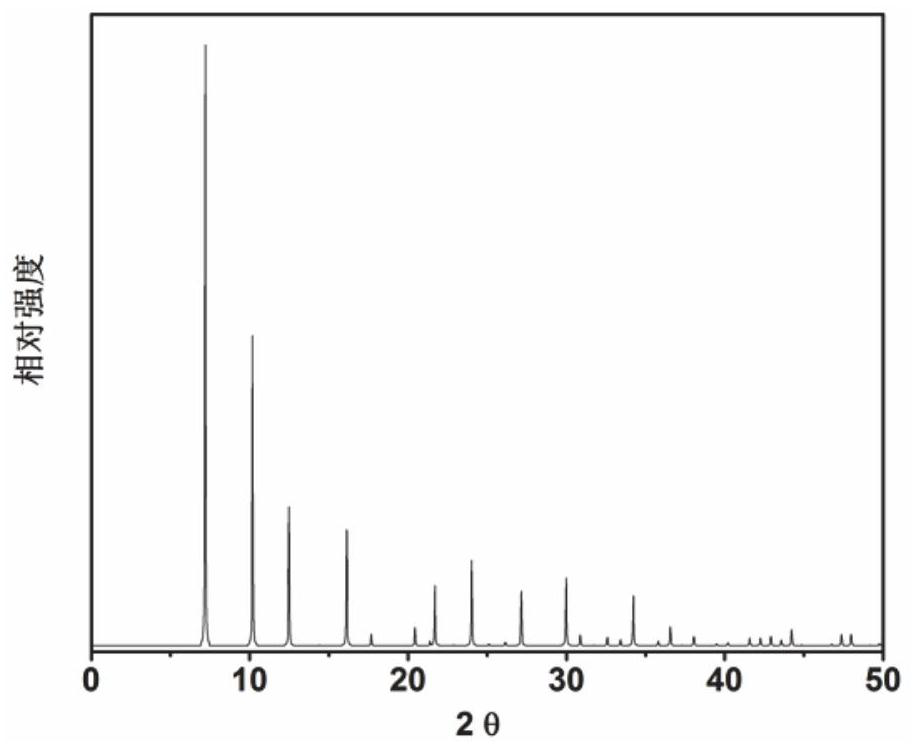

[0057] Embodiment 3: the synthesis of ZK-21 molecular sieve catalyst

[0058] 6.1g sodium aluminate (1.11Na 2 O·Al 2 o 3 3.5H 2 0) mix with a small amount of deionized water, add 23g concentration of 85% phosphoric acid, be made into 220ml aqueous solution, add 10.3g sodium metasilicate pentahydrate and 80ml deionized water while stirring, the gel obtained after fully stirring, then Put it into a stainless steel autoclave lined with polytetrafluoroethylene, and crystallize at a constant temperature of 100°C for 69h. After crystallization, use a centrifuge at 3000 rpm for 3 minutes, wash the separated solid product with deionized water until it is neutral, and dry it overnight in air at 100°C. The results of XRD analysis are as follows: image 3 shown. from image 3 It can be seen from the results that the synthesized product is the original powder of ZK-21 molecular sieve, and the original powder was calcined at 600°C for 5 hours to obtain ZK-21 molecular sieve, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com