Ferrite asphalt mixture with microwave snow melting function and preparation method and application thereof

A technology of asphalt mixture and ferrite, which is applied in the field of transportation engineering, can solve the problems of complex production process of non-traditional deicing agent, increase of soil pH value, decrease of soil enzyme activity, etc., and achieve low technical investment and simple production process , Increase the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

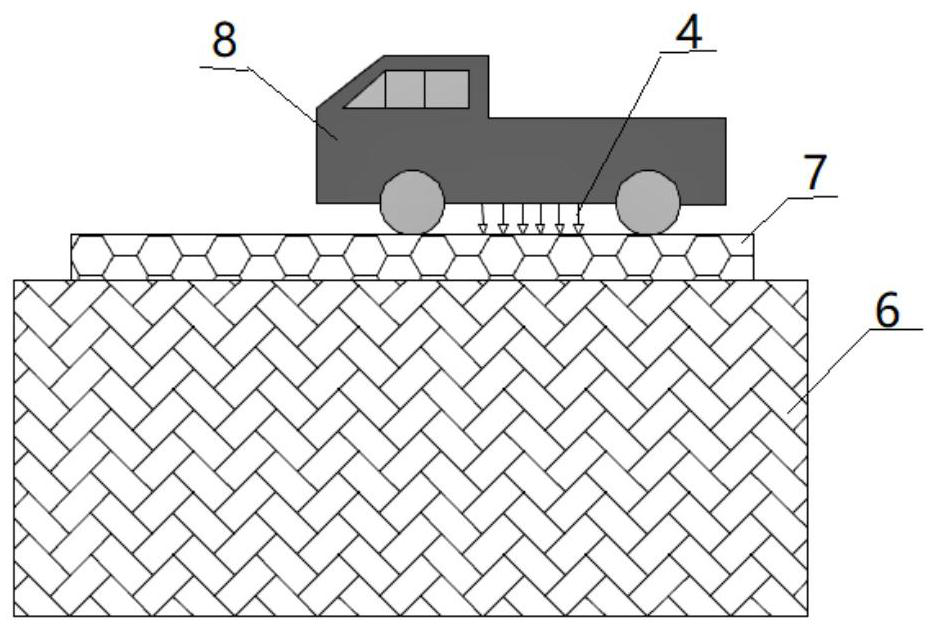

[0048] Using OGFC-13 gradation, the mass percentages of each raw material are: coarse and fine aggregates account for 87.1% (according to the gradation composition in Table 1), mineral powder accounts for 2.3%, high-viscosity asphalt accounts for 5.0%, zinc-manganese ferrite powder It accounts for 5.3% and fiber accounts for 0.3%. Heat the coarse and fine aggregates to 185°C and asphalt to 180°C, turn on the stirring pot, add coarse and fine aggregates, fibers, and high-viscosity asphalt successively, stir at 185°C for 90s, then add ore powder and zinc-manganese ferrite powder, stirred for 180s, formed the rut plate at 170-175°C, put it into the freezer to reduce the temperature of the rut plate to -20°C, and put it on the rut plate Cover the surface with a layer of snow, put it into a microwave oven and heat it for 5 minutes. The surface temperature of the test rut plate has risen to 5°C, and the surface snow has basically melted, which shows that it can realize the rapid heat...

Embodiment 2

[0050] Using OGFC-13 gradation, the mass percentages of each raw material are: coarse and fine aggregates account for 87.1% (according to the gradation composition in Table 1), mineral powder accounts for 2.3%, high-viscosity asphalt accounts for 5.0%, zinc-manganese ferrite powder It accounts for 5.3% and fiber accounts for 0.2%. Heat the coarse and fine aggregates to 185°C and asphalt to 180°C, turn on the stirring pot, add coarse and fine aggregates, fibers, and high-viscosity asphalt successively, stir at 185°C for 90s, then add ore powder and zinc-manganese ferrite powder, stirred for 180s, at 170-175°C, formed rutting boards, and stood for 24 hours for curing. Using the steady state method to test the thermal conductivity of two rutting plates at normal temperature, it was found that the thermal conductivity of the rutting plates mixed with ferrite increased by 0.46W / (m K) compared with the control group without adding, showing that the present invention can effectively i...

Embodiment 3

[0052] Using OGFC-13 gradation, the mass percentages of each raw material are: coarse and fine aggregates account for 89.5% (according to the gradation composition in Table 1), mineral powder accounts for 2.1%, high-viscosity asphalt accounts for 4.8%, zinc-manganese ferrite powder The fiber accounts for 3.4%, and the fiber accounts for 0.2%. Heat the coarse and fine aggregate to 185°C, heat the asphalt to 180°C, turn on the stirring pot, add coarse and fine aggregate, fiber, and high-viscosity asphalt successively, stir at 185°C for 90s, then add ore powder and zinc manganese ferrite powder, stirring for 180s. The test temperature is -10°C, and the size of the formed specimen is a small beam of 30mm×35mm×250mm. The low-temperature bending test is carried out on the mixed material specimen to test its bending tensile strength and bending stiffness modulus at failure. It is found that adding 3.4% Compared with the blank control group, the bending stiffness modulus of the ferrit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com