Method for preparing building material by complex microorganism mineralization

A technology of compound microorganisms and microbial strains is applied in the field of preparing building materials by microbial mineralization, which can solve the problems of poor volume stability and low utilization efficiency of building material products, and achieve the promotion of stable carbonate minerals and active minerals. Improved stability and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

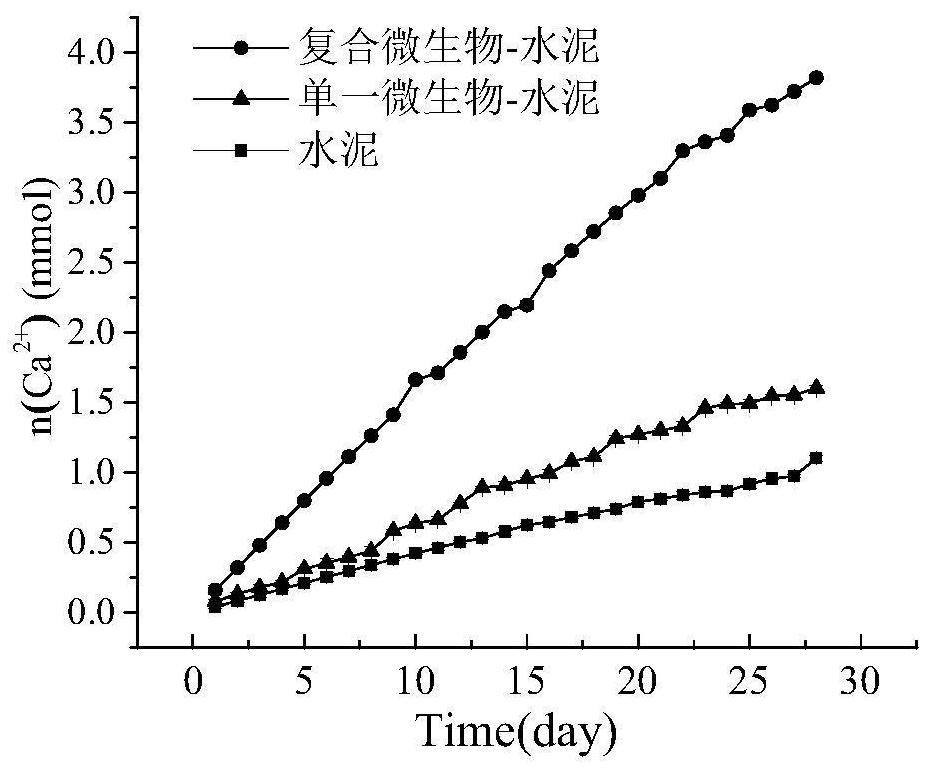

[0041] In this example, the microbial strain with the function of mineralization and deposition takes carbonic anhydrase-producing Bacillus colloid (ACCC10012) as an example, and the acid-producing bacteria adopts acetic acid bacteria (CICC 24425) that can ferment and produce acid.

[0042] The specific steps of preparing the composite microbial building material product in the present embodiment are as follows:

[0043] (1) Preparation of microbial additive A: inoculate acid-producing bacteria in the sterilized medium, each liter of medium contains 5-15 g of yeast extract, 10-20 g of agar, and 2-8 g of glucose, and then add the substrate organic The sugar content is 30-80g, placed on a shaker, and incubated at a constant temperature of 10-40°C and 50-200r / min for 6-48 hours, and the pH of the bacterial solution can be reduced to 3-6.

[0044] (2) Preparation of Microbial Additive B: Bacillus is inoculated into a sterilized liquid medium solution, and each liter of medium cont...

Embodiment 2

[0054] The microbial strains used in this example are the same as those in Example 1.

[0055] The specific steps of preparing the composite microbial building material product in the present embodiment are as follows:

[0056] (1) preparation of microbial additive A: with embodiment 1;

[0057] (2) preparation of microbial additive B: same as Example 1;

[0058] (3) Select ordinary Portland cement to prepare composite microbial cement-based material;

[0059] Add the microbial additive B to the fine powder containing calcium and magnesium minerals at a mass ratio of 1.5% of cement, and mix and stir the dry material evenly. Then mix the microbial additive A with water at a mass ratio of 5% of the fine powder, and add it to the mixed dry material. Stir evenly, and the specific ratio of cement carrying microorganism slurry: microorganism A: microorganism B: water by mass ratio is 1:0.05:0.015:0.3.

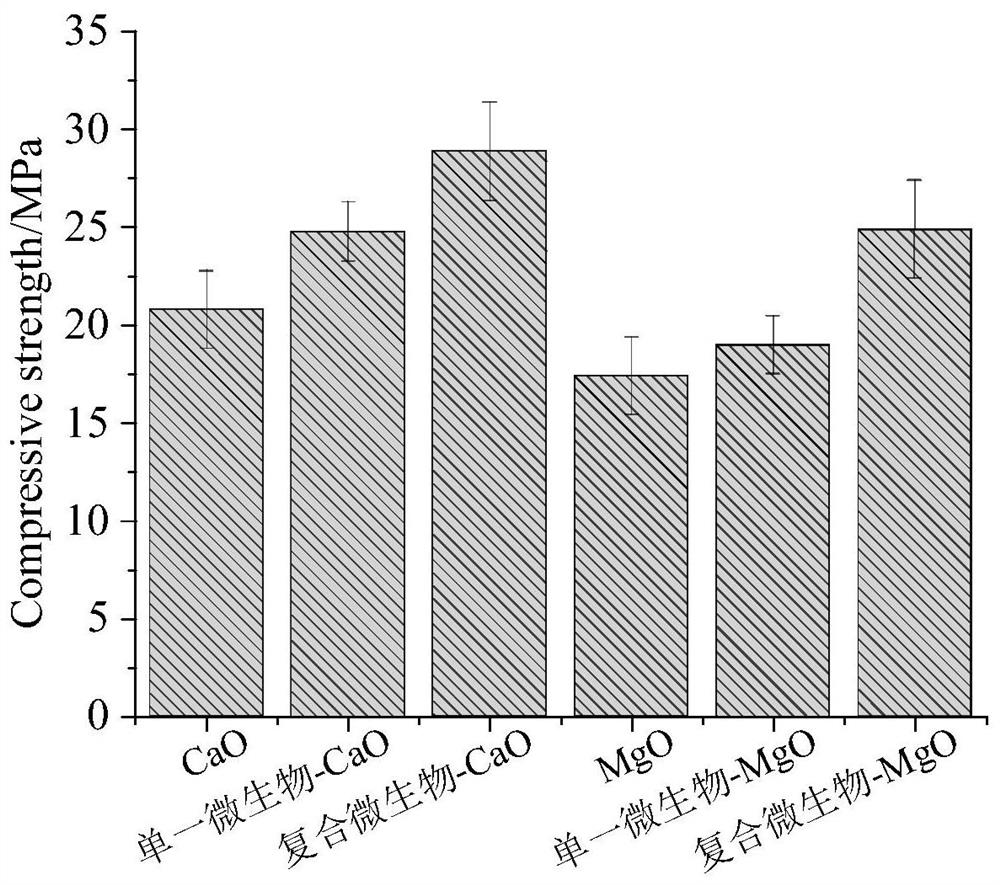

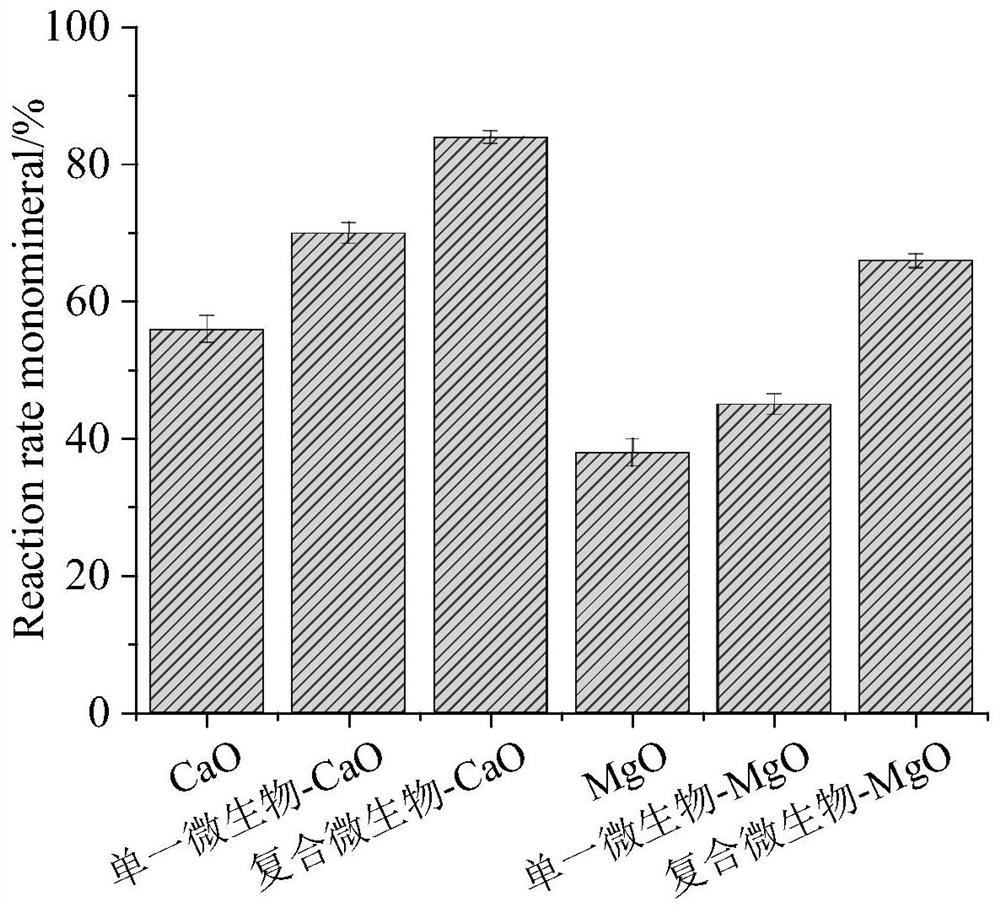

[0060] Then use it as a cementitious material, add sand at a ratio of 1:3 to ...

Embodiment 3

[0067] The microbial strains used in this example are the same as those in Example 1.

[0068] The specific steps of preparing the composite microbial building material product in the present embodiment are as follows:

[0069] (1) preparation of microbial additive A: with embodiment 1;

[0070] (2) preparation of microbial additive B: same as Example 1;

[0071] (3) Selecting steel slag with different fineness to prepare composite microbial steel slag cementitious material;

[0072] Add the microbial additive B into the fine powder containing calcium and magnesium minerals at a ratio of 2% by mass of cement, and mix and stir the dry material evenly, and then mix the microbial additive A with water at a mass ratio of 6% of the fine powder, and add it to the mixed dry material. Stir evenly, and the ratio of steel slag: microorganism A: microorganism B: water is 1:0.06:0.02:0.3 by mass.

[0073] Add sand according to the ratio of mortar to sand at 1:3 and stir evenly, as show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com