A portable machine tool for aluminum alloy plate processing

A kind of aluminum alloy plate, convenient technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the difficulty of increasing the operation difficulty of the gantry machining center, the inconvenience of the overall operation of the gantry machining center, and the increase of the difficulty of taking the aluminum alloy plate and other issues, to achieve the effect of reducing the difficulty of taking, increasing the scope of application, and stabilizing the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

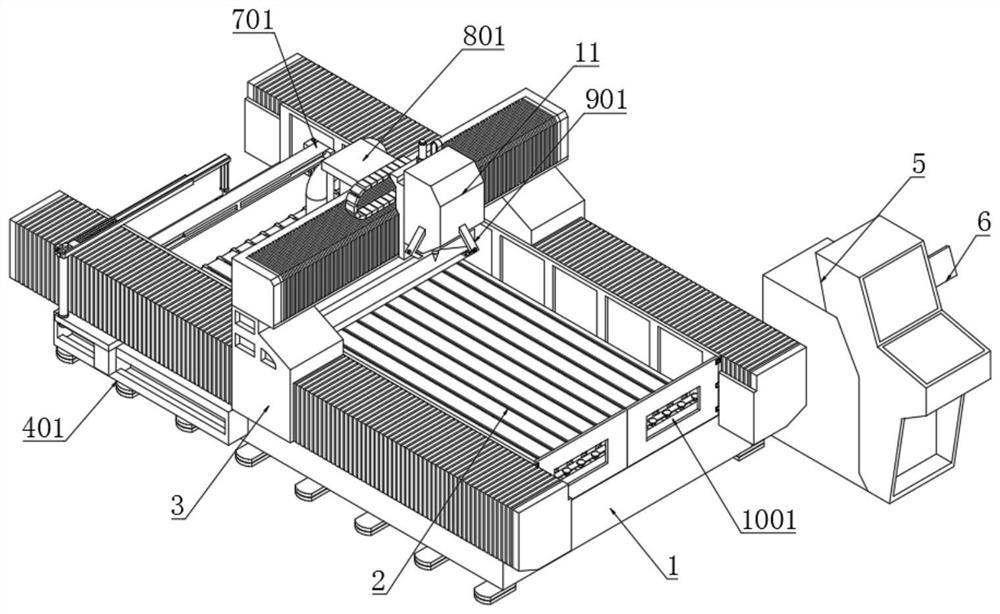

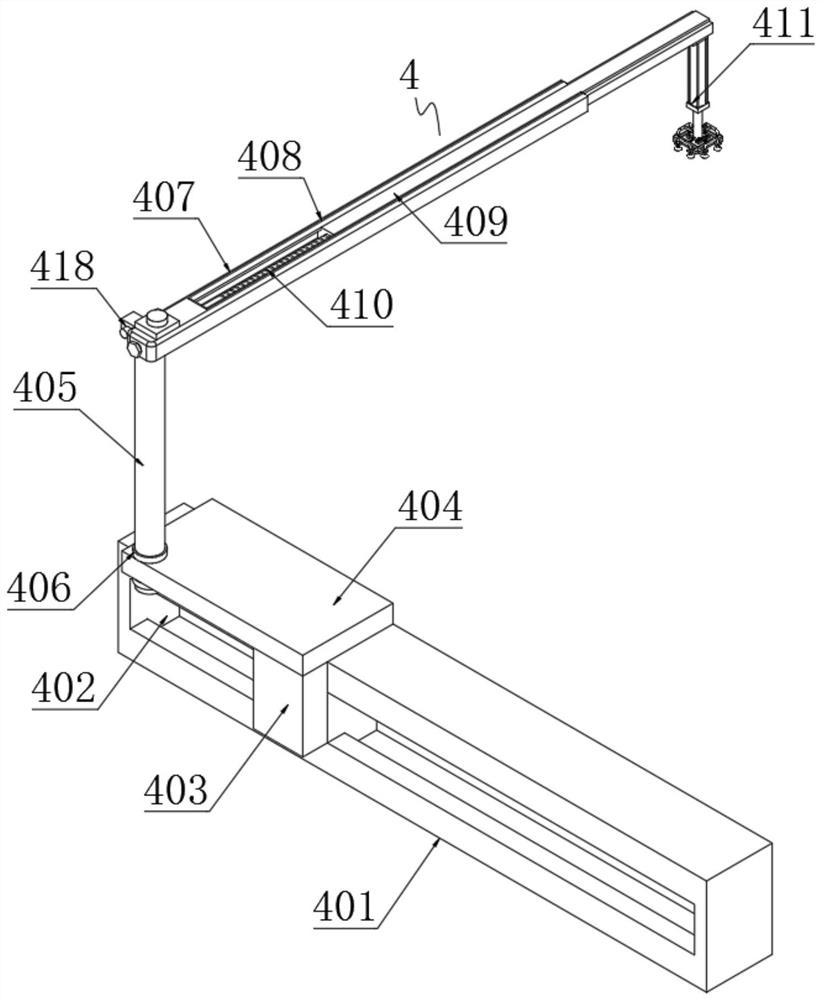

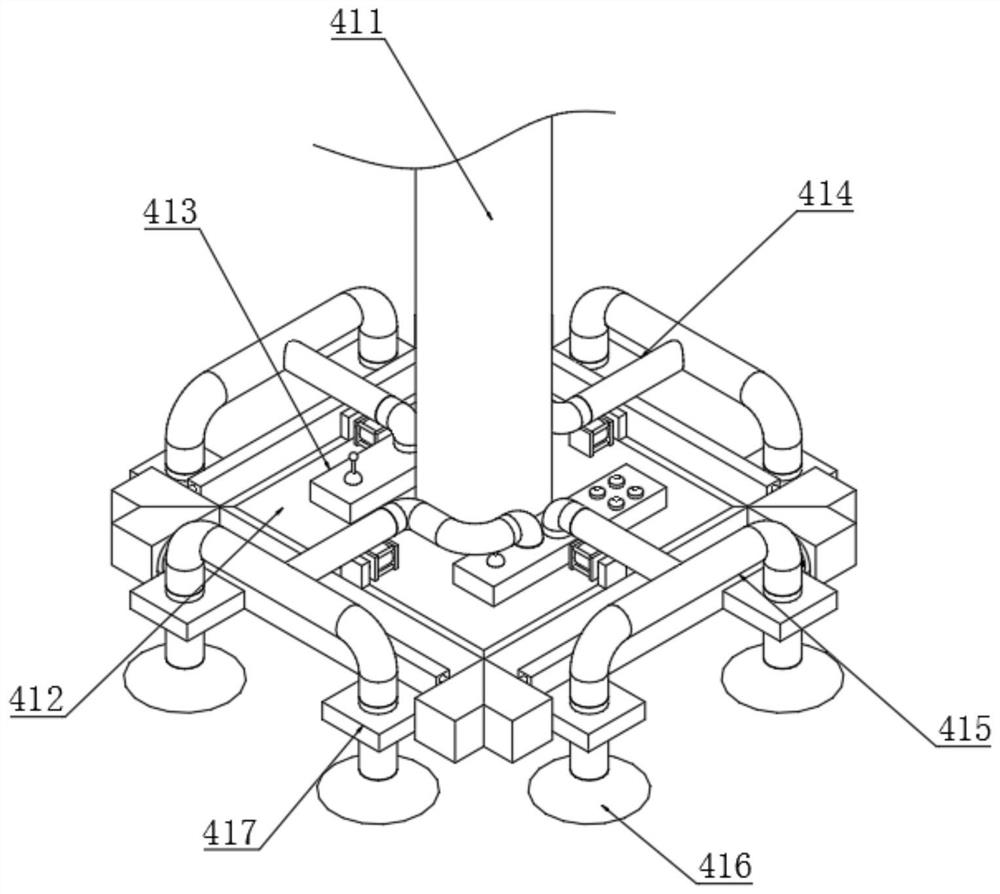

[0054] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, a portable machine tool for aluminum alloy plate processing, including a machine base 1, a workbench 2 is slidingly connected to the middle part of the top of the machine base 1, and a gantry is connected to the top of the outer surface of the machine base 1 for movement. 3. The middle part of one end of the gantry frame 3 is connected to the headstock 11 for movement, and the bottom side of the front and bottom of the machine base 1 is fixedly installed with a mobile fetching mechanism 4. The mobile fetching mechanism 4 includes a fixed plate 401, a main chute 402, a slider 403, and a main shaft. Connecting plate 404, column 405, positioning ring 406, rotating plate 407, from chute 408, slide bar 409, main screw mandrel 410, lifting cylinder 411, from connecting plate 412, air pump 413, air extraction pipe 414, connecting pipe 415, Vacuum suction cup 416, fixed block 417, contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com