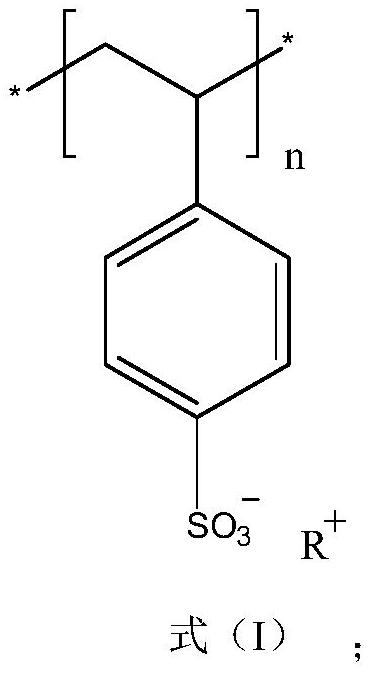

Application of polyvinyl benzene sulfonic acid or salt thereof as room-temperature phosphorescent material

A technology of polyvinylbenzenesulfonic acid and room temperature phosphorescence, which can be used in luminescent materials, applications, household appliances, etc., can solve the problem of less materials, and achieve the effect of strong luminescence, easy-to-obtain raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A halogen-free, water-based, room-temperature phosphorescent material, which uses sodium polyvinylbenzenesulfonate as a raw material and has a number-average molecular weight of 7000, is dissolved in water to prepare an aqueous solution with a mass fraction of 2%.

[0041] Use the solution prepared above as a raw material for printing, and the specific process is as follows: use 2% mass fraction of sodium polyvinylbenzenesulfonate aqueous solution to carry out letterpress printing on paper, and after printing, dry the paper at 70 degrees for 1 hour, and then it can be printed on A printed pattern with green fluorescence-green phosphorescence is left on the paper.

[0042] When the above patterns are directly placed in the air, due to the water absorption of the paper, the clusters will gradually lose their room temperature phosphorescent properties. In order to maintain the phosphorescent properties of the pattern, it can be protected by overmolding, so that the pattern...

Embodiment 2

[0045] A halogen-free, water-based room-temperature phosphorescent material, which uses polyvinylbenzenesulfonic acid as a raw material and has a number-average molecular weight of 7000, is dissolved in water to prepare an aqueous solution with a mass fraction of 0.2%.

[0046] The solution prepared above is used as a raw material for printing, and the specific process is as follows: use 0.2% mass fraction of polyvinylbenzenesulfonic acid aqueous solution to inkjet print on the ethylene terephthalate film, and then print the film After drying at 90 degrees for 15 minutes, a green fluorescent-green phosphorescent printing pattern can be left on the film.

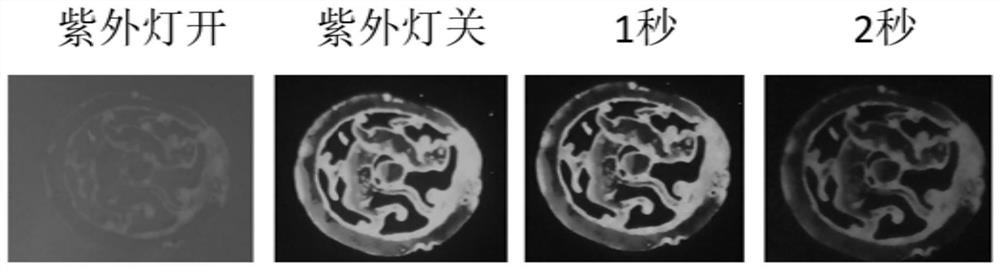

[0047]After plasticizing the film, a polymer film with room temperature phosphorescent patterns can be formed. Under the 365nm ultraviolet laser, the pattern shows green phosphorescence for 1.5 seconds after the light is turned off.

Embodiment 3

[0049] A method for preparing a halogen-free, water-based printing room-temperature phosphorescent material, using polyvinylbenzenesulfonic acid-melamine salt as a raw material, whose number average molecular weight is 7000, dissolving it in water, and preparing a polyvinylbenzenesulfonic acid-melamine salt with a mass fraction of 1%. aqueous solution.

[0050] Use the solution prepared above as a raw material for printing, and the specific process is as follows: use 1% by mass fraction of polyvinylbenzenesulfonic acid-melamine salt solution, screen-print on the self-adhesive film, and dry the paper at 70 degrees after printing After 1 hour, a printed pattern with blue fluorescence-blue-green phosphorescence can be left on the self-adhesive film.

[0051] Apply and protect with an acrylic paint that dries to form a long-lasting room temperature phosphorescent pattern on the self-adhesive film.

[0052] The prepared patterns and luminescent properties are as follows figure 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com