A kind of salt-tolerant structural polymer emulsion and preparation method thereof

A technology of polymer emulsion and salt resistance, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that clear water cannot meet a large amount of fracturing water, cannot meet the use of fracturing sand-carrying fluid, polymer or guanidine The problem of poor salt resistance of glue, etc., to achieve the effect of excellent sand carrying, good salt resistance, and good viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

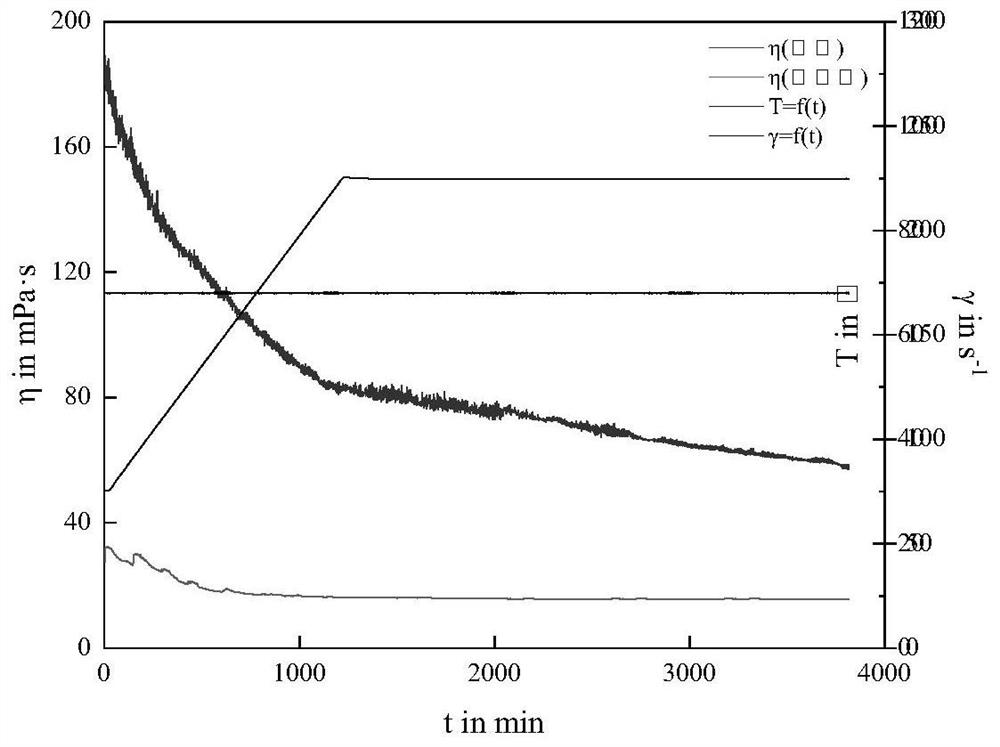

[0022] The preparation method of the salt-resistant structural polymer emulsion provided in this embodiment is as follows: in the first jacketed reaction kettle, add 340g of 3# white oil, 15g of Span 60, 40g of Span 80, and 30g of Tween 80, and start stirring to obtain oil. Phase; add 260g of water, 142g of acrylamide, 96g of acrylic acid, 15g of 2-acrylamido-2-methylpropanesulfonic acid, 52g of sodium hydroxide to adjust the pH of the solution to 6.5 in the jacketed reactor two, and control the neutralization temperature to be ≤30 ℃, add potassium persulfate 0.004g, azobisisobutyl cyanide 0.04g to obtain water phase; keep the speed of reaction kettle 1 at 240r / min, slowly pour the monomer aqueous solution in jacket reaction kettle 2 into the oil phase jacket In the first reactor, open nitrogen emulsification and deoxygenation for 30min, and control the temperature of the system at about 15 °C; use a metering pump to dropwise add 0.5% sodium bisulfite solution for polymerizatio...

Embodiment 2

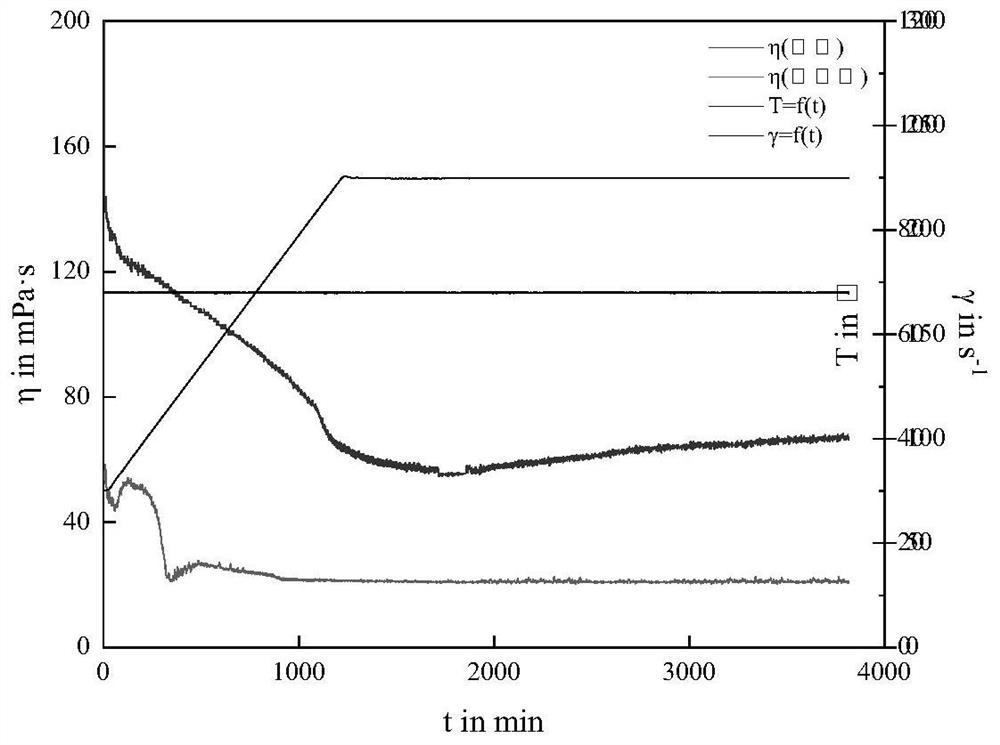

[0025] The preparation method of the salt-resistant structural polymer emulsion provided in this embodiment is as follows: in the first jacketed reaction kettle, add 340g of 3# white oil, 15g of Span 60, 40g of Span 80, and 30g of Tween 80, and start stirring to obtain oil. Phase; add 260g water, 142g acrylamide, 96g acrylic acid, 15g 2-acrylamido-2-methylpropanesulfonic acid, 6g dimethyl diallyl ammonium chloride (DMDAAC), 52g to the second jacketed reactor Sodium hydroxide was used to adjust the pH of the solution to 6.5, and the neutralization temperature was controlled to be less than or equal to 30°C. 0.004 g of potassium persulfate and 0.04 g of azobisisobutyl cyanide were added to obtain an aqueous phase; The monomer aqueous solution in the second reaction kettle was slowly poured into the first oil-phase jacketed reaction kettle, and the nitrogen emulsification and deoxygenation was turned on for 30 minutes, and the temperature of the system was controlled at about 15 °...

Embodiment 3

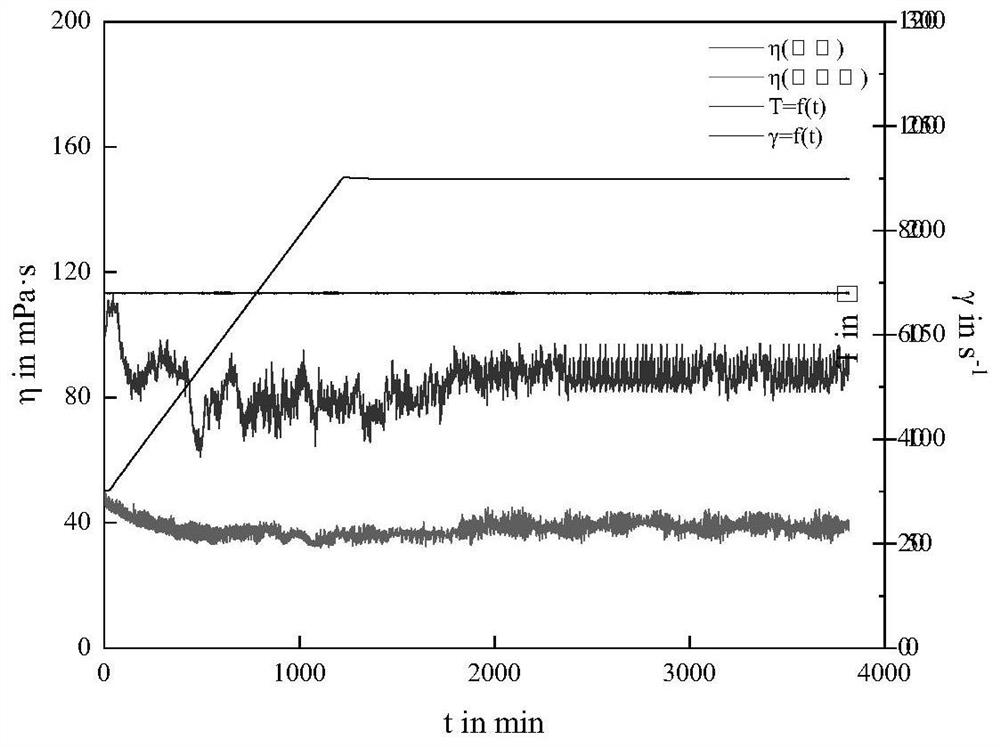

[0028] The preparation method of the salt-resistant structural polymer emulsion provided in this embodiment is as follows: in the first jacketed reaction kettle, add 340g of 3# white oil, 15g of Span 60, 40g of Span 80, and 30g of Tween 80, and start stirring to obtain oil. Phase; add 260g water, 142g acrylamide, 96g acrylic acid, 15g 2-acrylamido-2-methylpropanesulfonic acid, 10g dodecyl allyl ammonium bromide, 52g sodium hydroxide in jacketed reactor two Adjust the pH of the solution to 6.5, control the neutralization temperature to be less than or equal to 30°C, add 0.004 g of potassium persulfate and 0.04 g of azobisisobutyl cyanide to obtain a water phase; keep the first reaction kettle rotating speed at 240 r / min, put the jacketed reaction kettle two The medium monomer aqueous solution was slowly poured into the oil-phase jacketed reactor 1, and the nitrogen emulsification and deoxygenation was turned on for 30 minutes, and the temperature of the system was controlled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com