Barium strontium titanate-based dielectric ceramic material as well as preparation method and application thereof

A technology of barium strontium titanate and dielectric ceramics, which is applied in the field of electronic ceramic materials, can solve the problems of increased dielectric constant, decreased energy storage density, and decreased dielectric constant, achieving high dielectric constant, improved electrical resistance, good frequency stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] According to 0.27BaTiO 3 +0.22SrTiO 3 +0.13TiO 2 +0.036Bi 2 o 3 +0.29MgO+0.012Al 2 o 3 +0.04CaO+0.002SiO 2 Formulation composition weighing BaTiO 3 , SrTiO 3 、TiO 2 、 Bi 2 o 3 , MgO, Al 2 o 3 , CaCO 3 and SiO 2 Raw materials, using water as the medium and agate balls as the grinding medium, after wet ball milling for 24 hours, discharging and drying, pre-calcining the obtained powder at 1050°C for 6 hours; performing wet ball milling again, and drying to obtain the particle size It is a mixed powder of 0.5-1.0 μm; to the obtained mixed powder, add 0.8wt% polyvinyl alcohol (PVA) whose weight is the total weight of the mixed powder to carry out spray granulation, and then press under the isostatic pressure of 200MPa to form different Size green body; sinter the obtained green body at 1270°C for 10h, and then naturally cool to room temperature to obtain a ceramic block; cut and finely grind the obtained ceramic block to obtain length 300mm×width 40mm×thickne...

Embodiment 2

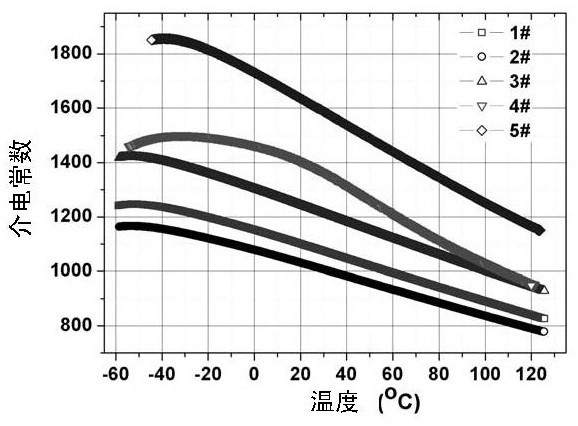

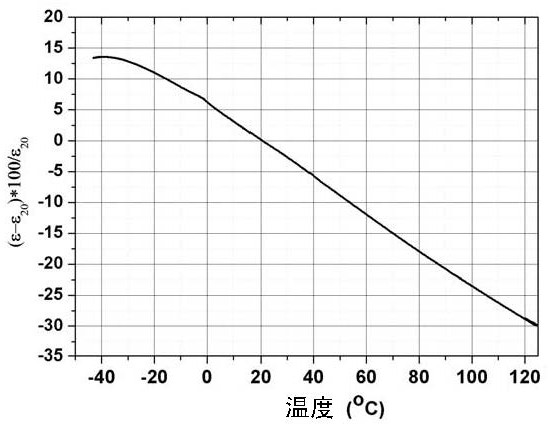

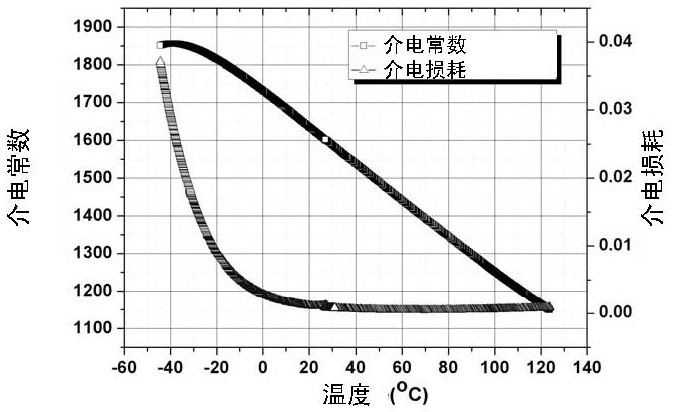

[0054] According to 0.25BaTiO 3 +0.20SrTiO 3 +0.13TiO 2 +0.036Bi 2 o 3 +0.33MgO+0.012Al 2 o 3 +0.04CaO+0.002SiO 2 Formulation composition weighing BaTiO 3 , SrTiO 3 、TiO 2 、 Bi 2 o 3 , MgO, Al 2 o 3 , CaCO 3 and SiO 2 Raw materials, ceramics were prepared according to the same process as in Example 1, and the sintering temperature was 1270° C. for 4 hours. Figure 10 Be the dielectric thermogram of ceramic in the present embodiment, Figure 11 It is the collection of graphs of the dielectric constant temperature change rate of the ceramics prepared in the embodiment of the present invention, by Figure 10 , Figure 11 It can be seen that the room temperature dielectric constant of the ceramics prepared in the embodiment of the present invention is about 1020, the dielectric loss is ~0.0024@1kHz, and the dielectric constant gradually decreases with the increase of temperature from -50°C, and the change rate is +4.6 ~ -4.7 (@-0℃~40℃). The electric strength at ...

Embodiment 3

[0056] According to 0.28BaTiO 3 +0.23SrTiO 3 +0.15TiO 2 +0.04Bi 2 o 3 +0.245MgO+0.013Al 2 o 3 +0.04CaO+0.002SiO 2 Ceramics were prepared according to the same process as in Example 1, and the sintering temperature was 1270° C. for 4 hours. Figure 12 Be the dielectric thermogram of ceramic in the present embodiment, Figure 13 It is the collection of graphs of the dielectric constant temperature change rate of the ceramics prepared in the embodiment of the present invention, by Figure 12 , Figure 13 It can be seen that the room temperature dielectric constant of the ceramics prepared in the embodiment of the present invention is about 1228, the dielectric loss is ~0.0004@1kHz, and the dielectric constant gradually decreases with the increase of temperature from -50°C, and the change rate is +5.0~- 4.9(@-0℃~40℃). The electric strength at room temperature is ~38.4kV / mm, 48.7kV / mm (@1mm, 0.38mm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com