Application of strengthening materials for concrete protective layer, composite template cloth and strengthening of concrete protective layer

A technology of strengthening materials and composite formwork, which is applied in the processing of building materials, formwork/formwork components, layered products, etc., can solve the problem of limited strengthening effect of concrete protective layer, reduction of water-cement ratio of surface concrete, no chemical reinforcement, etc. problems, to achieve the effect of improving mechanical properties and durability, shortening the maintenance period, and improving the strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

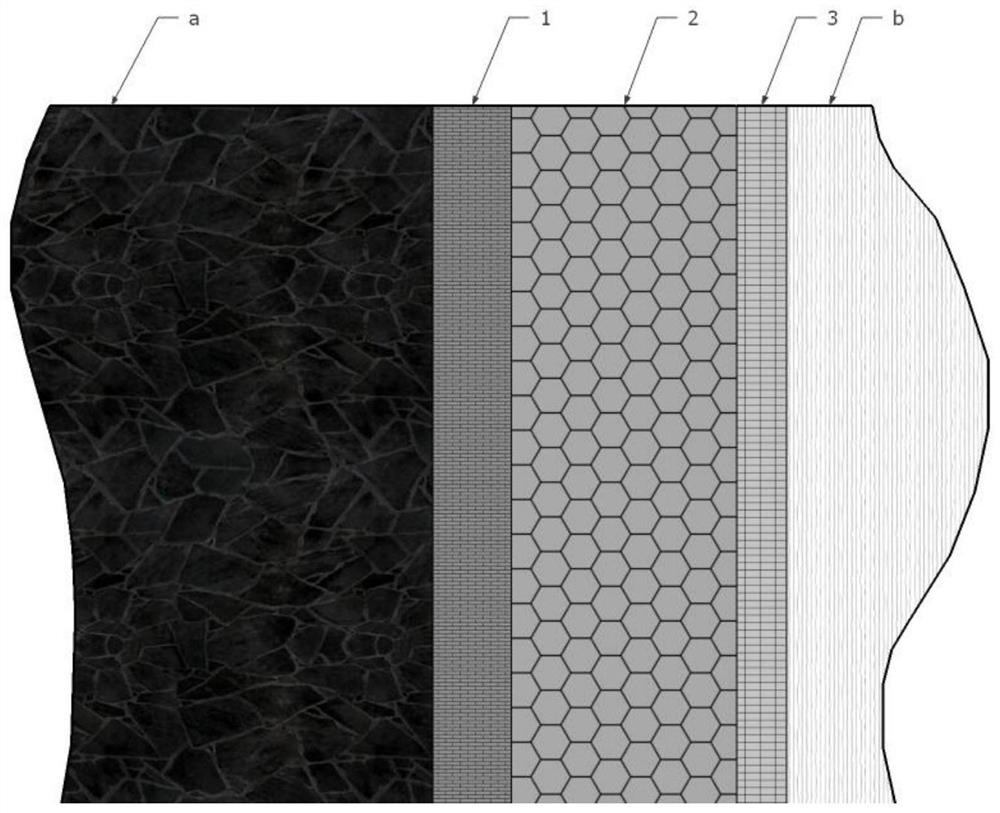

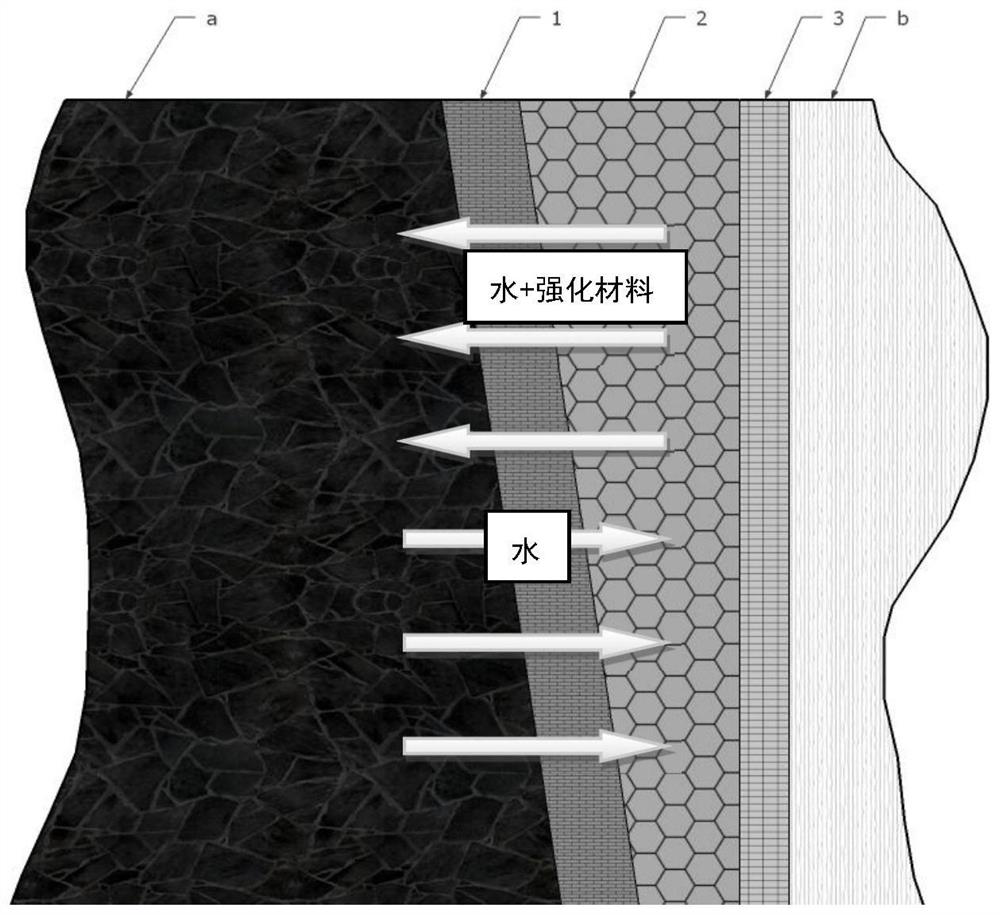

[0069] Water-permeable and breathable non-woven fabrics and water-repellent non-woven fabrics produced by Jusheng Company are used to make the surface layer and base layer respectively. The thickness of the water-permeable and breathable non-woven fabrics is 0.9mm, the pore size is 30μm, and the pore thickness of the water-repellent non-woven fabrics is 0.1mm. The pore size is 10μm; the middle layer of deformable material is produced by Yuanyuan Company with a density of 22kg / m 3 The K324 sponge package is finally compounded and becomes the composite template cloth of the present invention.

[0070] A proportion of the concrete protection layer strengthening material (strengthening slurry) according to the present invention is made up of the following substances by mass percentage: silica sol: 45%, nano-silicon dioxide: 10%, magnesium fluorosilicate: 13%, go Ionized water: 32%, and mixed uniformly by a magnetic stirrer in a water bath environment at 22±2°C, and the dosage is 5...

Embodiment 2

[0072] Water-permeable and breathable non-woven fabrics and water-repellent non-woven fabrics produced by Jusheng Company are used to make the surface layer and base layer respectively. The thickness of the water-permeable and breathable non-woven fabrics is 0.9mm, the pore size is 30μm, and the pore thickness of the water-repellent non-woven fabrics is 0.1mm. The pore size is 10μm; the middle layer of deformable material is produced by Yuanyuan Company with a density of 22kg / m 3 The K324 sponge package is finally compounded and becomes the composite template cloth of the present invention.

[0073] A proportioning of the concrete protective layer strengthening material (slurry) of the present invention is made up of following material by mass percentage: Silica sol: 50%, nano silicon dioxide: 12%, magnesium fluorosilicate: 15%, deionized Water: 23%, mixed uniformly by a magnetic stirrer in a water bath environment at 22±2°C, and the dosage is 5% of the cement mass.

Embodiment 3

[0075] Adopt the composite template cloth structure of the present invention, coordinate existing conventional strengthening agent, specifically:

[0076] Water-permeable and breathable non-woven fabrics and water-repellent non-woven fabrics produced by Jusheng Company are used to make the surface layer and base layer respectively. The thickness of the water-permeable and breathable non-woven fabrics is 0.9mm, the pore size is 30μm, and the pore thickness of the water-repellent non-woven fabrics is 0.1mm. The pore size is 10μm; the middle layer of deformable material is produced by Yuanyuan Company with a density of 22kg / m 3 The K324 sponge package is finally compounded and becomes the composite template cloth of the present invention.

[0077] Use commercially available Anhui Tairun concrete surface enhancer TR-HNTBMZQ, dosage 0.8kg / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com