Pore diameter tester of copper wire drawing die

A wire drawing die and tester technology, which is applied in wire drawing dies, manufacturing tools, metal processing, etc., can solve problems such as unusable and inability to test the inner wall wear of the wire drawing die, and achieve the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

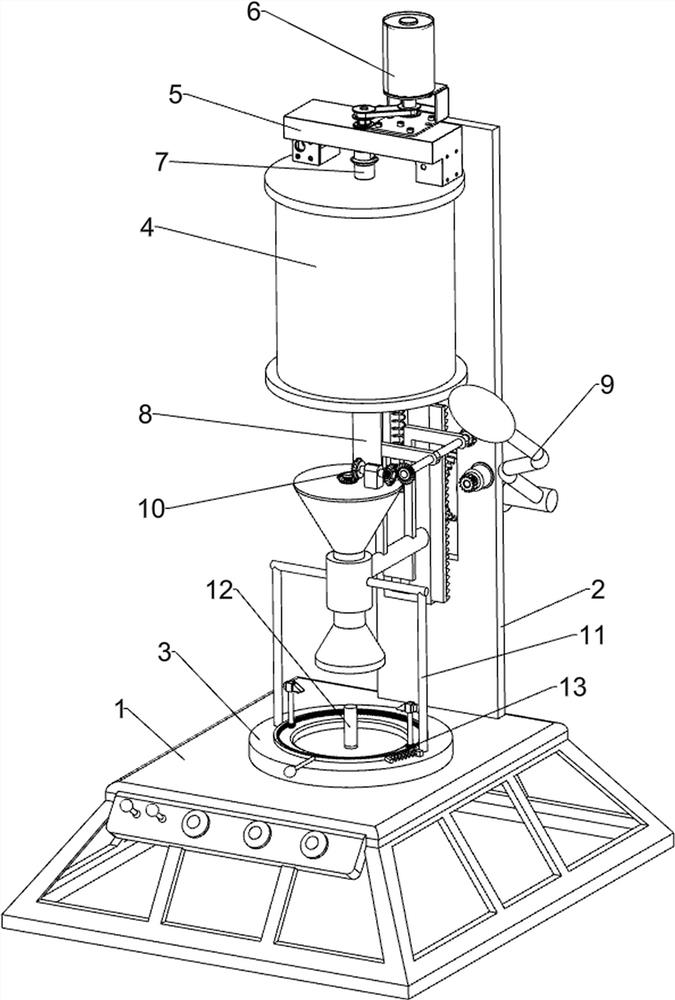

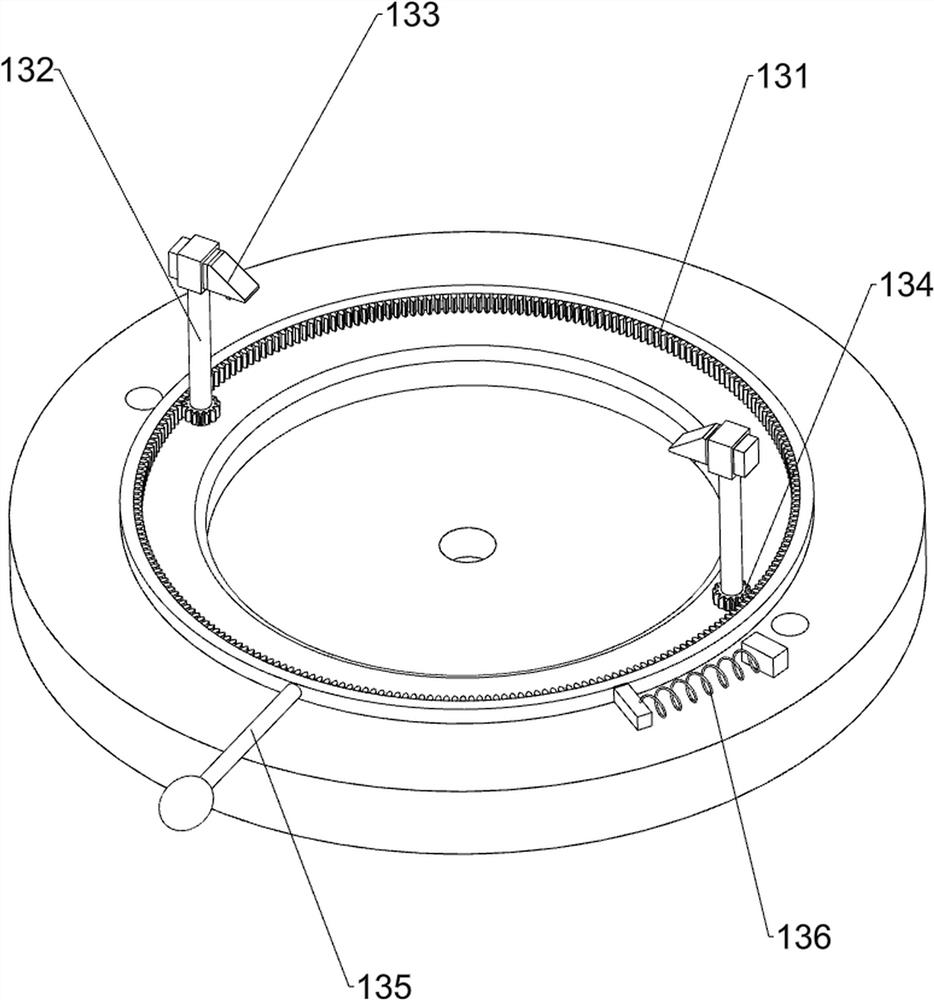

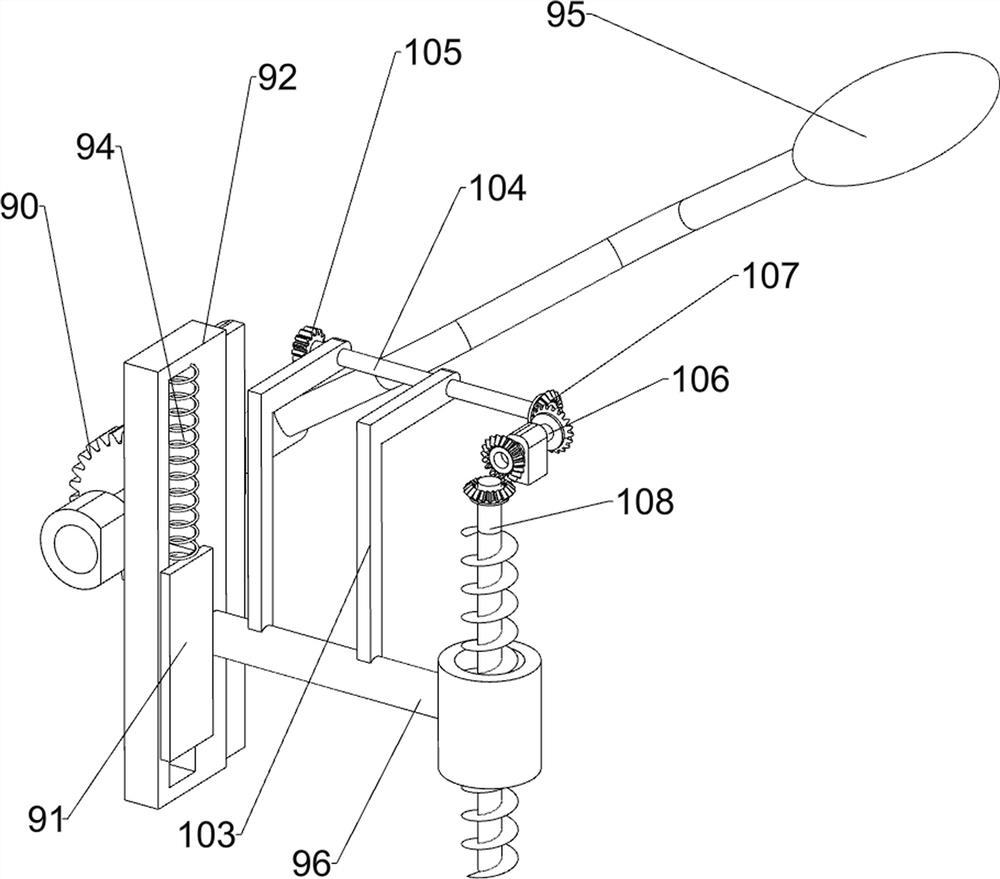

[0024] A copper wire drawing die aperture tester, such as Figure 1-3 As shown, it includes a base 1, a mounting plate 2, a mold placement seat 3, a heat preservation bucket 4, a support 5, a stirring motor 6, a stirring shaft 7, a telescopic material guide tube 8, a closing mechanism 9 and a filling mechanism 10, and the top of the base 1 The rear side is equipped with a mounting plate 2, the middle of the top of the base 1 is connected with a mold placement seat 3, the front side of the top of the mounting plate 2 is connected with a heat preservation bucket 4, the top of the heat preservation bucket 4 is connected with a support 5, and a stirring motor 6 is installed on the support 5 , the output shaft of the stirring motor 6 is connected with the stirring shaft 7, the stirring shaft 7 is located in the heat preservation barrel 4, the telescopic material guide pipe 8 is connected to the bottom of the heat preservation barrel 4, and the closing mechanism 9 is installed in the...

Embodiment 2

[0029] On the basis of Example 1, such as figure 2 As shown, it also includes a guide connecting frame 11 and an extrusion rod 12. A guiding connecting frame 11 is slidably connected between the left and right sides of the mold placement seat 3, and the top of the guiding connecting frame 11 is connected with the connecting rod 96. The guiding connection An extrusion rod 12 is connected in the middle of the inner bottom of the frame 11, and the extrusion rod 12 runs through the mold placement seat 3, and the extrusion rod 12 is slidingly connected with the mold placement seat 3.

[0030] When the wire drawing die is put into the mold placement seat 3, the wire drawing die is set on the outside of the extrusion rod 12. When the connecting rod 96 moves downward, the guide connecting frame 11 drives the extrusion rod 12 to move downward. When the connecting rod 96 moves upward When moving, the extruding rod 12 is driven upward by the guide connecting frame 11, and the upward mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com