A new energy vehicle exhaust pipe rear muffler assembly welding method

A new energy vehicle, welding method technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient welding, increase the difficulty of fabrication, cumbersome fixing and disassembly process, etc., to simplify the fixing. Steps, the effect of quick disassembly

Active Publication Date: 2022-05-31

东莞市明仕汽车零部件有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The muffler and the exhaust pipe are fixed by welding, and the shape of the rear muffler is also different, such as round and oval, etc. When welding the place where the muffler is in contact with the exhaust pipe, it is necessary to The muffler and the exhaust pipe are fixed, and the existing fixing fixture has the following disadvantages: one, when the oval-shaped muffler is fixed, a plurality of pressing plates are required to be fixed in multiple points, and when each pressing plate is fixed, It needs to be operated separately, which makes the fixing and dismounting process cumbersome; 2. When the oval muffler is welded in an exhaust pipe, because its lower half is blocked, it increases the difficulty of fabrication during welding and is inconvenient to weld

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

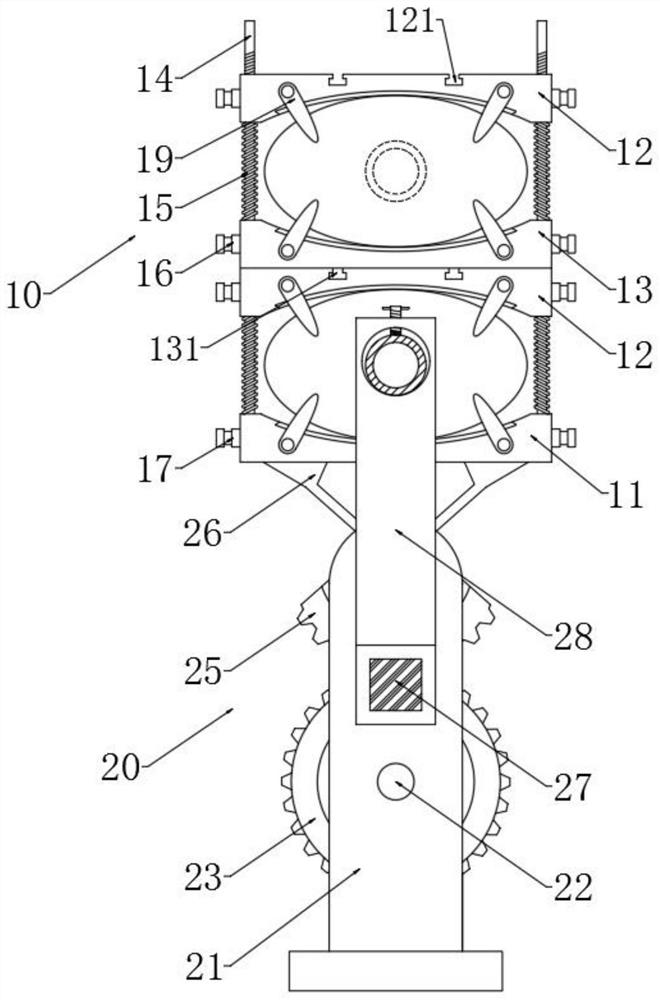

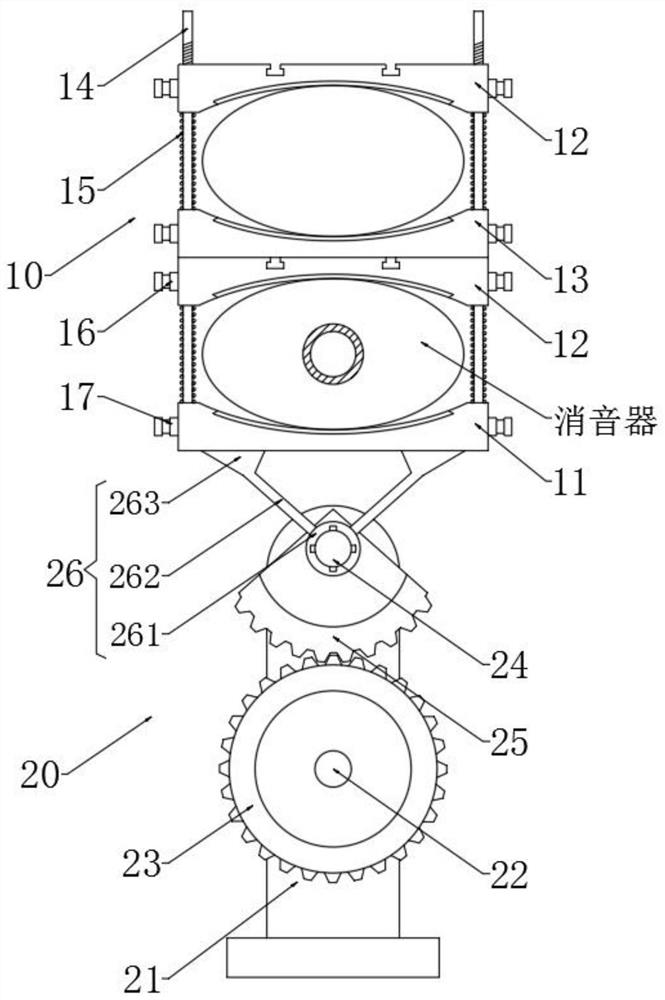

[0036] The front faces of the support plate 11, the first pressing plate 12 and the second pressing plate 13 are symmetrically provided with a limiting mechanism 19, and the limiting mechanism 19

[0037] The angle adjustment device 20 includes mounting plates 21 symmetrically arranged at the front and rear ends of the support plate 11.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

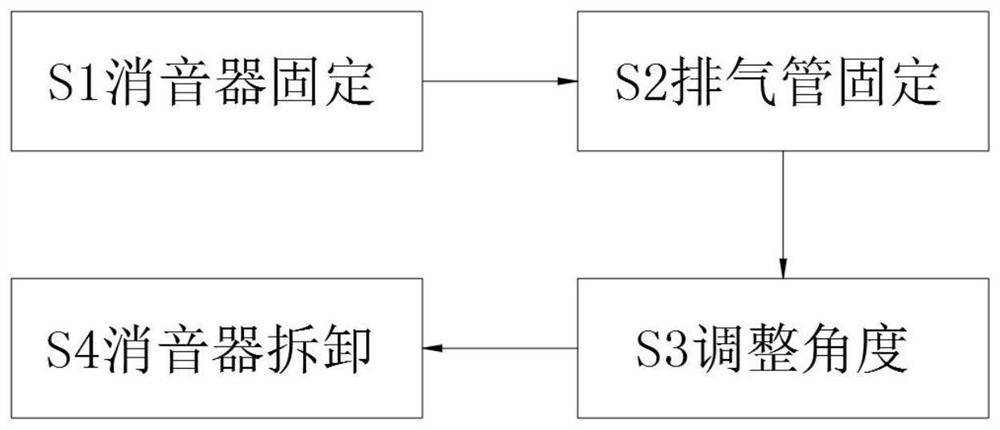

The invention relates to a method for assembling and welding a rear muffler of an exhaust pipe of a new energy vehicle. The method for assembling and welding a rear muffler of an exhaust pipe adopts the following fixing machine, the fixing machine includes a clamping device for clamping the muffler, The bottom of the clamping device is provided with an angle adjustment device. The present invention squeezes and fixes the muffler by tightening the pull cord to make the first pressure plate approach the support plate, and uses one pull rope to simultaneously drive multiple first pressure plates to move without separately fixing the multiple first pressure plates. The fixing steps are simplified; and when the pull cord is unfolded, the first pressure plate bounces upwards under the action of the spring at the same time, which can realize the quick disassembly of the clamp; the invention drives the incomplete gear to rotate a certain angle through the gear, thereby driving the supporting mechanism to follow Rotate, the clamping device clamps the muffler and also rotates synchronously, which is convenient to turn some places that are not convenient for welding to places that are convenient for welding.

Description

A new energy vehicle exhaust pipe rear muffler assembly welding method technical field The present invention relates to the technical field of muffler assembly, in particular to a new energy vehicle exhaust pipe rear muffler group Mounting welding method. Background technique Automobile muffler is mainly used to reduce the noise generated when the engine of the motor vehicle works, and its principle is that the automobile exhausts The trachea consists of two pipes of different lengths, which are separated first and then meet, due to the difference in length of the two pipes The value is equal to half the wavelength of the sound wave emitted by the car, so that the interference of the two trains of sound waves when they are superimposed cancels each other out and weakens The sound intensity reduces the incoming sound, thereby reducing the noise. [0003] The muffler and the exhaust pipe are fixed by welding, and the shape of the rear muffler is also different. Circu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K37/04B23K37/047

CPCB23K37/0435B23K37/047

Inventor 陈明亮

Owner 东莞市明仕汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com