A low power consumption induction heating power control system

An induction heating and power control technology, applied in the direction of induction heating control, induction heating, etc., can solve the problem of large power design margin of insulated gate bipolar transistors, inability to ensure the on-off of insulated gate bipolar transistors, and large grid pollution, etc. problem, to achieve the effect of simple structure, reasonable design, and low switching power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0024] It should be noted that the descriptions involving "first", "second" and so on in the present invention are only for the purpose of description, and should not be understood as indicating or implying their relative importance or implicitly indicating the quantity of the indicated technical features. Thus, the features defined as "first" and "second" may explicitly or implicitly include at least one of these features.

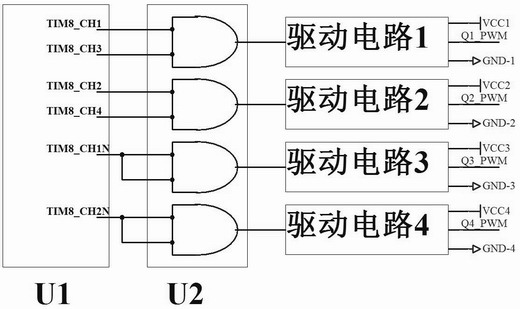

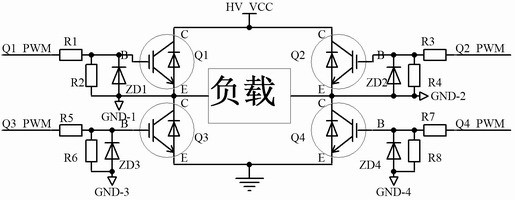

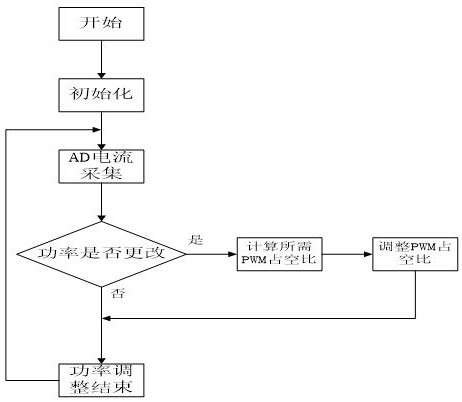

[0025] see Figure 1~Figure 3, the low-power induction heating power control system preferably implemented in the present invention includes a sequentially connected controller, a driver device, a load drive circuit, and a load. The controller controls the on-off of the load drive circuit through the driver device, and the load drive circuit controls the load by The set indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com